I’ve heard replicas described as paper-dolls for grown men, and it’s true.

There is a subset of owners who like the idea of trying this or that and seeing how well they like it. I didn’t start out in this hobby thinking I’d be that guy, but here I am-- serving as a cautionary parable for all that can go sideways when you sacrifice treasure and reason in pursuit of… something.

Because a replica Speedster starts out as a simple device, how it’s festooned and fitted changes the flavor from one thing to the next. Unfortunately, this is one of the things I like (or tell myself I like) about owning my particular plastic fantastic. One can follow the worm-hole down as far as one wishes to go. There is no bottom.

Deciding what I want the car to be has always been the hard part for me, and it’s changed from one thing to another more than a few times over the years. Molding the car into one thing is hard enough, but attempting to make it into two things at the same time is an order of magnitude more difficult. My particular dysfunction has been trying to make it many things at once, which is a bit like alchemy.

I want my car to be good looking, race-car light, modern-car fast, handle well, and able to travel long distances in reasonable comfort. I’ve also been 100% committed to an archaic air-cooled power-train designed about 90 years ago to be cheap and disposable. None of the circles on the Ven diagram overlap easily, so I’ve fettled endlessly-- if not exactly robbing Peter to pay Paul, then borrowing from him, commoditizing the debt, bundling it, and selling it in an auction.

My solution over the years has tended toward adding complexity (often to the point of convolution) in an attempt to solve what I believe to be a complicated problem. This is antithetical to the original intent and primary appeal of these cars, but no matter-- it has been my little science project over the years.

I'm only happy when it rains

I'm only happy when it's complicated

And though I know you can't appreciate it

I'm only happy when it rains

Garbage

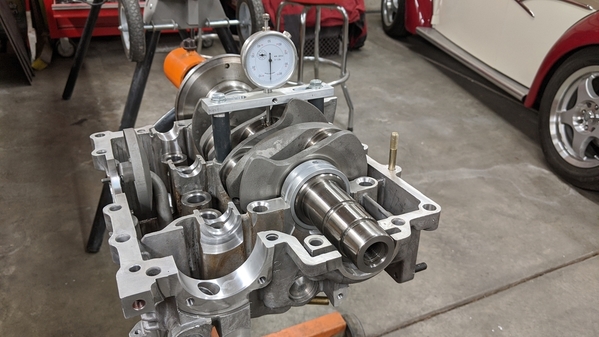

Dry-sumping allowed me to lower the car past where I’d have been able to with any extended sump. It also enabled me to use 911 oil sprayers to cool the under-side of the pistons, (due to the increased capacity of the pressure side of the pump, and because windage doesn’t matter so much when there’s no oil in the sump). The sprayers gave me the courage to bump compression up as well.

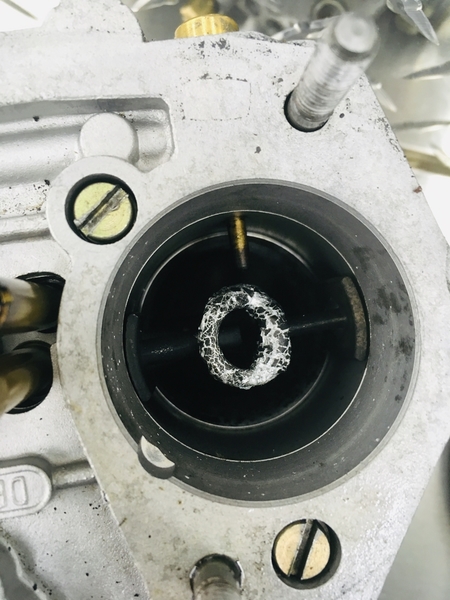

Then there is the twin-spark setup. The idea behind this is that with two flame fronts, combustion can be completed more quickly across a larger diameter cylinder. In theory-- this allows a higher compression ratio without pre-ignition, and should reduce the amount of total timing advance needed for complete combustion.

In addition to all of this, I also used thermal coatings in the combustion chambers, exhaust ports, and piston tops. The twin-plug thing required a kind of science project ignition, asking people to build things that were not commercially available. I have gotten very, very lost inside my own head over the years. I’ve sometimes struggle to determine if all this has kept me sane or driven me mad, but regardless-- the resulting car has been awesome

… except when it hasn’t been.