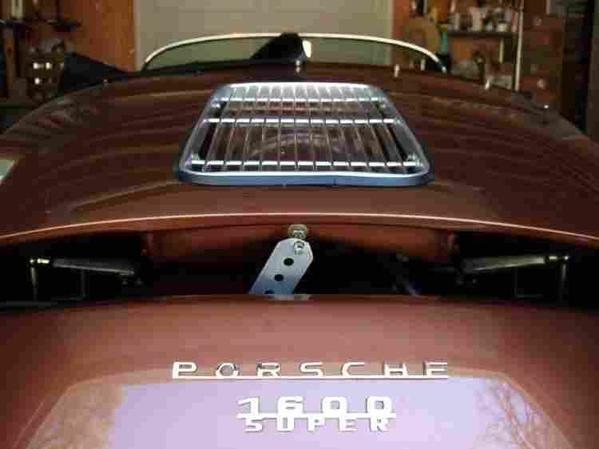

Just about finished with my VS car project. Engine should go in next week. My question is: do you really need that hole on the firewall? Seems like air flow might be ok without it but would love some input on it before I install??? Any thoughts? The engine is a 1965 356 SC Porsche, a little healthier than stock. Thanks for your time. Scott

Replies sorted oldest to newest

Apparently old VS did not have it - they added it for a reason, I'd think. CMC has a similar cut out way back to the early '80. Not easy to cut out once engine is installed.

If you look at the design of your fiberglass engine lid you'll probably notice there is not a lot of air intake; compound that with the fact that at higher speeds the negative air pressure over it wants to pull air out (and not let air in), I think you'll see that another way for air to enter the engine compartment is needed. With the hole in the firewall (in front of the fan intake in the shroud), positive air pressure from below the car (as much as 2 psi) flows into the engine compartment at higher vehicle speeds. Holes in the sides of the engine compartment (right by the aircleaners) can be beneficial too. The more air you get through (notice that word) the engine compartment, the cooler it will run, as air flowing through will remove the heat radiating off the engine, instead of it recirculating back into the fan and the carburetors.

You'll know you've got it right when a remote thermometer in the engine compartment reads close to the ambient temp outside the car. If you run an extra oil cooler, above the trans or on the front of the firewall is not the place for it, as it will preheat the air going into the engine compartment.

Hope this helps. Al

It has been noted by a couple members that the hole in the firewall is only so beneficial; maybe we should be looking at more places where the air can exit the engine compartment?

These are air-cooled and air-breathing engines.

They need air.

The more air the better.

Original 356's didn't have the compartment in front of the engine compartment that our replicas do, so a hole in the firewall would have made a funny looking hole in the back seat.

But we can cut a hole in the firewall without messing up the back seat. And that hole is a good thing. It opens into a space that is open to under the car, where air pressure is higher than in the engine compartment when the car is moving.

Opening that hole brings more airflow into the engine compartment, which is a good thing.

The more air the better.

Look what Porsche did to the deck lid of the 356 as their engines got more powerful and produced more heat. First, in the Carrera, they cut louver-shaped holes. Then, later on, they cut two great big holes where there had been only one. Holes in the engine compartment are a good thing.

The more air the better.

But even if you don't believe this, look at it like @ALB does.

A hole in your firewall saves weight.

And that's a good thing, too.

PS: Looks like ALB and I were typing at the same time. Oh well, the more air the better.

Leaving the lower bulkhead open ( 1.5 - 2") will increase clean cool air to the motor, I do this on every build, you'll need a 1/4" coarse screen over the fan intake to stop leaves etc. from getting ingested into the shroud.

Air is funny.

It goes places you think it won't, and stays out of places you think it would naturally want to go. Aerodynamics is rocket science, or at least part of it. I'm pretty sure Herr Doktor (and his team of sainted German Engineers) didn't do any legit aero testing on his speedster afterthought. If he did, he missed the boat on getting air into the engine compartment.

We've talked a lot about our theories over the years, but the simple fact is: these engines require A LOT of air to cool well, and the shape of a speedster is not conducive to naturally feeding it what is needed.

The cooling fan spinning away back there is capable of ingesting huge amounts of air, as is the engine itself. All that air gets sucked in on the topside of the engine and pushed out the bottom (or out the exhaust). It's not an inconsequential requirement, and indeed is the very goal of what is trying to be accomplished. If the engine compartment could be a positive pressure zone (relative to the underside of the car), we'd always have enough air for cooling and/or the engine. We almost never do. I think this basic fact is often overlooked with all the talk of "in and out."

The fact is, unless the air is coming in the top and going into the fan and out the bottom (or down the carb throats), there could be an in/out hurricane through the engine compartment and it wouldn't do a single thing to cool the engine. It's all about getting the air to the fan so it can go over the heads and out the bottom.

Regarding firewall holes: I've had none, and I've had two big ones with blower fans. The fans and the holes don't hurt anything, I guess, but they don't help anything either. I've got several hundred bucks and a lot of time in my holes/fans. They look neat and make a cool noise, so I guess there's that. Any air they are pushing into the engine compartment is hot, so there's the flip side of that.

The easiest and best thing I've ever seen or done is to build a really simple set-up, whereby I can pop the deck-lid about 2". This lowers oil temps about 5*-10* on average-- because more air is coming into the engine compartment. If I could rig up a "ram-air" setup like the 10" duct running through the engine compartment Al puts up now and again, I would. Otherwise, I'd spend $5 on a deck-lid standoff, and know I had done all there was to do.

It would be fairly simple to fabricate a flat blade type scoop under the trans area kind of like a "Cow Catcher" ( bet there are many here that don't know what that is :~)

Almost all of us know we need more air to our engines, both air & water-cooled. Clean, unobstructed, ambient temperature air helps our engines. But that's about the extent of agreement. As Stan said, air is tricky. A lay person would think you could mount a wide, thin funnel-shaped opening right under the front bumper, then send that air back to the engine inlet area, through an elliptical tube or hose, mounted either on the firewall, or very near, and voila, problem solved.

However, that's not how air movement really works. There's boundary air considerations, surface friction, laminar flow, and other complicated considerations. Most efficient is a slightly smaller opening in front, then a tube or pipe that increases my no more than 7% to get the most efficient air flow where it's needed. F1 cars normally use those mechanisms for brake cooling, cockpit cooling, and some heat exchanger cooling. An example of the above: if you want 36 square inches of air cooling, your opening in the front of the car would be no greater than about 18 square inches, with a slight but continuing increase in pipe size to the device being cooled.

I am not a scientist by any means, but most of what I've learned is counter-intuitive to what I consider common sense. If you have a large opening in the front of the car with unobstructed air, the ram effect only works until you reach speed, nominally over 35 mph, then flow stalls, with a complicated pattern of diffused air that goes nowhere. That's why the inlet needs to be smaller than the outlet. Strange, eh?

From my experience, it's easy to find a completely dumbed-down explanation of air movement, and it's also easy to find a completely scientific explanation of the same. Unfortunately, neither end of the spectrum is very helpful to me. That middle-of-the road explanation is not available, or, better said, I have yet to find it.

I'm no genius, but I like to think I have above average intelligence. However, trying to understand air flow has caused me to reconsider where I stand in the intelligence spectrum. I know we have some scientists in our midst. Perhaps there are just too many holes in my old bucket, and you guys can set me straight.

Alan Merklin posted:It would be fairly simple to fabricate a flat blade type scoop under the trans area kind of like a "Cow Catcher" ( bet there are many here that don't know what that is :~)

...and that's why, when I built Whitecloud's engine, I ran a 4" duct from the firewall hole to the front-right wheel well. It "rams" fresh air into the engine compartment at most speeds and gives me that warm, fuzzy feeling, knowing my engine's feeling exactly the opposite...

Remember these on old Baja's? This guy must collect birds with the air horns.

It's not quite that easy. Really.

Keep that hole open. If you really don't like it, just make a plate to cover it up. That way you can remove the cover later if you feel that you need it. More important is what you do with that open space at the rear of your engine compartment where you can look in and see the backside of your tail lights. That whole area has to be sealed off. You have a VS and that area is not....... so it acts like a big SCOOP to collect the hot air that went through the engine already and give it back to the fan to do it again ! You need to block off that area.Some photos are attached of how I did it. It's pretty easy and nearly any material can be used like fiberglass or sheet metal. You should really familiarize yourself with two other things regarding your engine lid ( "hood") The grille is adequate for enough air flow but underneath, the air turns 90 degrees, right and left, into a very restricted area before it reaches the engine compartment. This is a flow restriction problem area. Above you read raising the hood 2 inches and many other suggestions (including that hole your talking about). All those will do the job to reduce or eliminate air flow restriction but you really need to take care of that rear heat scoop I'm pointing out. The best time to deal with that is NOW before you install your engine.

Hope this helps........here's some photos........Bruce

Attachments

Alan Merklin posted:It would be fairly simple to fabricate a flat blade type scoop under the trans area kind of like a "Cow Catcher" ( bet there are many here that don't know what that is :~)

Something to do with the front end of a locomotive ?....

Like Stan, I installed a fan behind That Hole because, well, it just has to make things better, right? Maybe what's best about it is that I control the fan with a toggle switch, and stuff you turn off and on with a toggle switch is just cool.

But there's something else going on here besides oil temperature and head temperature. And that would be carb temperature. The carbs are affected by temperature, too. All of those little passages with fuel and air running through them expand and contract as the carb heats up and cools down. You may have noticed that your engine runs differently when it's hot than when it's cold or warming up and that's mainly because the carbs themselves change with temperature.

A troublesome thing on many of these engines is what happens when you park after driving for a while on a hot day and try to restart after 10 or 15 minutes. It coughs and sputters and runs like hell for a few minutes until it 'clears up'.

When you park, with no air passing through the engine compartment, the carbs get hotter than when you're driving, gas can percolate in all those little passages, and air bubbles form where they really shouldn't be.

I've found that running that little fan while I stop for gas, or for a few minutes after shutting down, greatly reduces this tendency to run rough after a stop.

I've also talked myself into believing that the little fan helps reduce engine compartment temps when I'm driving in warm weather, too.

Please don't try to burst my bubble. The ritual of the Toggle and Fan has become part of my personal religious beliefs and my world would crumble if I discovered I was worshipping false gods. Besides, we true believers are not easily swayed.

Can I get an amen?

Firewall holes, no firewall holes, switched fans, cow-catcher blades, ambient air temperatures, air pressure shunts...

I have no angst over any of those things. I just drive!

J.K.....BWAAAAAAA HAAAAAAAAAA HAAAAAAAAA! ![]()

![]()

Your shunt is a replica...

Jim, you're my hero.

I dream of some day being free of this curse of the demon fan. But I have a long way to go. The first step is admitting I have a problem, but I'm afraid I'm still trapped in denial.

For now, I need my fan.

Will is that why you have a small rats nest in that car every winter as the varmint travels up the air hose ![]()

Jim have you got an air flow diagram worked out yet that makes you move that Radiator to the front yet ? ![]()

Amen, Mitch!

Ray,

I just returned from 3 weeks in the US, and finally seem to have my overcooling woes controlled. I even went over the dreaded "Grapevine", Tejon pass in Central California, twice in one day as a test, and ran the twisties with Troy and Robert M for fun. An enterprising mechanic actually removed every coolant hose in an attempt to find an obstruction and get to ground zero. The attached picture is what he found in one cooling hose, a 1/2" male x 1/8" barb brass hose fitting. The picture shows a generic but accurate representation of the fitting. The actual one is in my pocket. I work it into general conversation and whip it out with fervor.

I can't envision the scenario in which the placement of that fitting would occur accidentally. After removing it, then it was just a matter of adjustment for fan controllers, electric water pump, heat exchangers, etc. Pretty weird, eh? Since I have been bashing a certain manufacturer for many years, I can't help but make a connection. If there is such a thing as karma, he will twist in the wind one fine day. At least that's what I tell myself.

Attachments

To cool my engine bay temperatures I fabricated a standoff for my IM's engine hood.

It didn't have any effect on my oil/head temperatures but it sure did cool down the surface of the shroud, alternator, carb, etc.

After a drive during the summer months, with the engine lid closed, I couldn't rest my hand on the shroud, alternator, etc. After a drive with the lid popped open 4 inches I could.

Attachments

What the heck?

MusbJim posted:I have no angst over any of those things. I just drive!

Oven, no oven... I have no angst over those things. I just cook!

J.K.....BWAAAAAAA HAAAAAAAAAA HAAAAAAAAA! ![]()

![]()

ALB posted:What the heck?

If you are referring to Jim's 1/2" MPT x 1/8" barbed fitting, I agree-- "what the heck?"

If you are referring to Ron's stand-off, I can tell you that this little thing makes more difference than all the what-not we talk about regarding holes, airflow through the engine compartments, etc. I have no idea why it works, but it does.

" I have no idea why it works, but it does."

That's how my "tuner son", who's totally fluent in EFI mapping, feels about ANY carburetor. He believes that rebuilding a carburetor simply restores its' Mo-Jo.

Jim: That mechanic that found the restrictor deserves a case of really good hooch!

Attachments

Not sure how you'll squeeze an errant brass barb fitting into a conversation with umbrella drinks in Fiji. I'd start off with Lane's missing brass carb piece that took several months to diagnose! Th STIG says he pulled out his hair trying to resolve that one! I like it when an obvious cause surfaces - far better than issue magically going away, unexplained. Like the time I rebuilt my MGC engine and it wouldn't start - called my dad who came by and observed the dizzy rotor sitting on the work bench - Dooh!

aircooled posted:Keep that hole open. If you really don't like it, just make a plate to cover it up. That way you can remove the cover later if you feel that you need it. More important is what you do with that open space at the rear of your engine compartment where you can look in and see the backside of your tail lights. That whole area has to be sealed off. You have a VS and that area is not....... so it acts like a big SCOOP to collect the hot air that went through the engine already and give it back to the fan to do it again ! You need to block off that area.Some photos are attached of how I did it. It's pretty easy and nearly any material can be used like fiberglass or sheet metal. You should really familiarize yourself with two other things regarding your engine lid ( "hood") The grille is adequate for enough air flow but underneath, the air turns 90 degrees, right and left, into a very restricted area before it reaches the engine compartment. This is a flow restriction problem area. Above you read raising the hood 2 inches and many other suggestions (including that hole your talking about). All those will do the job to reduce or eliminate air flow restriction but you really need to take care of that rear heat scoop I'm pointing out. The best time to deal with that is NOW before you install your engine.

Hope this helps........here's some photos........Bruce

Still have any templates lying around?? I need to do this next!

There is a good write up on the rear exhaust shield in the CMC/FF build manuals posted here. CMC supplies precut (but fitting is req'd) fiberglass pieces for the rear. One goes below the steel cross bar and the other goes above it. The one that goes above is fitted around the rear tail lights and gets fiberglassed in both for a good seal and to add strength to overhanging rear fiberglass.

Attachments

Jim, Great news that you finally solved the issue. ![]() How the heck can a hose fitting fall off and get into that hose? But solving that issue by removing all the hoses was BRILLIANT. Sometimes going back to the real simple stuff you find errors in logic, extr pieces, dropped hose barbs and hopefully never any instruments inside one of your body cavities

How the heck can a hose fitting fall off and get into that hose? But solving that issue by removing all the hoses was BRILLIANT. Sometimes going back to the real simple stuff you find errors in logic, extr pieces, dropped hose barbs and hopefully never any instruments inside one of your body cavities ![]() Just reading about you chasing that heating issue was a nightmare, Welcome back to sanity, ... Ray

Just reading about you chasing that heating issue was a nightmare, Welcome back to sanity, ... Ray

Never cars are smoothing out and closing out the front engine compartment to stop the air from going into the engine compartment which seems to be a real benefit to slip streaming and aerodynamic efficiency.

Stan wouldn't the lift cause airflow on top of the rear lid and cause air to be drawn out of the engine compartment air. Only speculating.

Windtunnel testing is an art and many things paradoxically are not what they seem ![]()

Longfella...No I don't sorry to say. Did have them but they went out in the last garage clean up. It's really not a difficult job to make them if you have the engine out and the car up on stands. You can sit on the floor inside your engine compartment comfortably with some good heavy duty poster board, scissors, and cut-to-fit one. Use my photos to get the general size and concept. I bought some of the flat fiber glass sheeting that Kirk at VS uses for the other panels around the engine. (VS is only 1/2 hour from me). He squawked a little about giving me some because he gets it from the people who make the bodies and was short on it. If you wanted to use this, ask him to send you some or you can make your own on a piece of melamine from home depot, fiber glass matting and resin. Band saw or saber saw for the cutting......You could make this shield out of sheet aluminum or sheet metal as well. I made mine so it's removable. Two of those tabs rest on the 2" by 2" square tubing. I drilled and tapped the tube to accept 10X32 machine screws to fasten down the shield. The rest of the edges of the shield are sealed to the body with silicone sealant.....nice and air tight when finished and still removable with the engine in. I used Justice Brothers epoxy to "weld" the pieces of the fiber glass shield together. This is a really clean and nice looking installation when completed. I painted it black to match everything else. I hope this helps you.......Bruce

* You can order a partial sheet of aluminum that is epoxy painted black on both sides.... you'll have quite a bit left over.

* Kind thinking someone may have put that fitting into the hose as a flow restriction?

Brian - I forget.......is your car a CMC? Regardless, I have full-size, HD craft paper templates for a CMC in two pieces:

1 big horse shoe piece surrounding the engine (it mates up to stock VW engine tins)

1 piece that fits across the rear of the engine compartment effectively sealing the back and above the tail lights

They will cost you postage (about $6-7 bucks, last time I sent some out)

I made my shields out of HVAC sheet metal. Easy to work/cut/drill/bend and a local HVAC contractor gave me a bunch, once he found out what it was going into, but I used a pretty large sheet for the horse shoe piece. It would be easy to make that up from three smaller pieces.

aircooled posted:Longfella...No I don't sorry to say. Did have them but they went out in the last garage clean up. It's really not a difficult job to make them if you have the engine out and the car up on stands. You can sit on the floor inside your engine compartment comfortably with some good heavy duty poster board, scissors, and cut-to-fit one. Use my photos to get the general size and concept. I bought some of the flat fiber glass sheeting that Kirk at VS uses for the other panels around the engine. (VS is only 1/2 hour from me). He squawked a little about giving me some because he gets it from the people who make the bodies and was short on it. If you wanted to use this, ask him to send you some or you can make your own on a piece of melamine from home depot, fiber glass matting and resin. Band saw or saber saw for the cutting......You could make this shield out of sheet aluminum or sheet metal as well. I made mine so it's removable. Two of those tabs rest on the 2" by 2" square tubing. I drilled and tapped the tube to accept 10X32 machine screws to fasten down the shield. The rest of the edges of the shield are sealed to the body with silicone sealant.....nice and air tight when finished and still removable with the engine in. I used Justice Brothers epoxy to "weld" the pieces of the fiber glass shield together. This is a really clean and nice looking installation when completed. I painted it black to match everything else. I hope this helps you.......Bruce

I made mine in a few hours. Not 100% perfect but they work. Check my build thread. I could send outlines of them if you're nice.

When I was redoing my engine area, I made an insert for the firewall.

Used cardboard as a template. From that I made a mold and molded an insert. That insert then screws to what I left of the body molded in firewall.

I then covered the air inlet hole with 1/2" hardware wire.

When removed, it , makes working on the engine easier. It also allows for a peice of bulb weatherstrip from the top of the front engine sheetmetal.

Attachments

Hi Alan,

Yes, someone did put that fitting inside the hose as a flow restrictor, but their intent was malicious, not helpful. Unfortunately, slowing down coolant to that extent creates all kinds of problems after the engine reaches temp. It's just like having a thermostat that never opens fully.

I cut the 6" hole in front of the fan intake and covered it with 1/4" hardware cloth and omitted the front gasket seal.

Sealed up the rear with aluminum flashing , which was supposed to be the prototype , but it worked so well, I cleaned it up and painted it black. I have no oil cooler or fans and do not prop open my deck lid.

I installed port holes in the sides of the engine compartment in the wheel wells to get at #1 and 3 spark plugs and thought that I could open them if I was running through the desert or such but that ain't gonna happen.

My puny little 1904cc runs cool all the time as long as I keep it at least 2500 RPM. But that's me living in the north east and every one and every car is different. Have fun

Wow, Jim! I'm just glad to hear that you have the overheating issue sorted out. I assume that a certain manufacturer had access to your car at some point after the "relationship" went south. That is despicable if your suspicions are true.

In any case, good news that it is running right.

I have been pleasantly surprised that after all the work done on my 2110cc, including new exhaust and some customized tins to accommodate it, the car actually runs cooler in the Panhandle of Florida than it did in the corn fields of Illinois. I run an oil cooler and fan mounted on the cabin side of the firewall. No firewall hole and all tins in place.

Your engine is undoubtedly more sophisticated than mine, but too hot is never good whether it's a Suby or a T1.

Congrats on the fix!!!!