Today i hooked up my new FAST AFR meter and went for a drive. What a mess ! Idle was 12/1. Cruise was 9.5/1. De-cell was 15/1. So back to the garage for a jet change. I have Weber 44s on a 2110cc CB engine kit. The jets I started with are 145 mains.F-11 emulsion tubes, 175 air correction jets, and 65 idle jets. This isn't what CB sent to me in the carbs but I wanted to experiment with some different jetting.Turns out that my logic wasn't so good so back to the drawing board. Jeeze....these carbs are really sensitive in the idle jet area!! I'll let you guys know what I find as I go....continued.......Bruce

Replies sorted oldest to newest

Bruce- Are you running a combination vacuum/mechanical advance (svda) or mechanical only (009, 010, 019, or ??) distributor? The reason I ask is it will make a difference how you tune them. What did the carbs come with originally? Right off the start I'd say the idle circuit is rich, but you already know that...Al

65s are HUGE for that engine! Try 55. I ended up with 57s.

Mine are 57's too. Also a 2,110 running Del'lorto 40's

Mains are something like 162.5 (a convenient drill size I had in my kit that happened to work when I drilled out my 155's).

I tend to run about 13/1 a lot of the time, and it leans out to about 16/1 for about a second if I really stomp it at about 50mph.

Robert.......The ideal textbook number is 14.7:1 at cruise but as you can see from other comments, that varies to some extent. At idle, it's usually richer (a lower number) At high speed/RPM it's not good get too lean (a higher number) things start to melt then. Hope this helps

Al...I'm using a 009 mech. only. I don't know what the carbs. were originally built for.

Yup...right now they are so rich that the AFR Meter doesn't register anything lower than 9:5 it just flat-lines if it's richer. I'd be interested in what you have to say about the tuning differences of those various distributors.

The next "jet set" I installed are 155 mains, 200 air corrections, and 60 idles. I haven't tested them yet because the wife has me putting up Christmas decorations inside and out and we have company. By the looks of your comments I think I will be closer to goal. I'd like 13:1 at Idle, 14:7 at cruise, and 15:1 on decel. Accel will probably be all over the place but ideally, not to lean for very long as Gordon points out.......Bruce

A mechanical advance distributor is entirely rpm dependant and really only set up for idle and full throttle, and doesn't react to throttle position at all. A vacuum/mechanical unit (svda) adds timing at lighter throttle settings, and this allows you to safely jet the idle circuit somewhat leaner, resulting in better mileage and cooler running at part throttle cruising. John Connolly at Aircooled.net says- "...This will result in a lean-cruise that is cooler than 13:1 and max power without the risk of hurting the engine. The engine may run A/F ratios of over 20:1 safely this way."

We use mech advance distributors because (for the most part) they are what's available and easiest to set up/tune, while just about all factory ignition systems (for any car) have used vacuum as well for I don't know how long now. I remember John saying in a post (on the Samba) that a properly tuned engine with an svda will get 4mpg more than with a mechanical only distributor. And if the mechanical curves are similar the engine will make the same power at full throttle with either distributor.

A piece of advice- start with the idle circuit, get it running where you want it before moving on the the mains, and don't change more than 1 thing at a time. It can be hard to tell what caused the difference when doing multiple things at one time.

Do your carbs have vacuum ports?

PS- If you're genuinely interested in using an svda I'll find John's specific tuning instructions; his quote is the end of specific tuning instructions. Al

A guy can spend a lot of time on jetting, and get pretty lost. I've been really lost in the past, and so have a lot of other guys. Everything I know now (and it isn't a lot) regards Dellorto DRLA carb sets. This is where I've chosen to become a very, very sick man. I own at least 4 of every idle, air correction, and main jet from impossibly small to stupidly huge. I've got an Innovate LM1 A:F gauge and a German snail tool, and it's how I tune. Your mileage may vary.

When I started in this hobby, I spent about 4 Saturdays really screwing up a set of 40 IDFs. I thought I'd never get the hang of it. I tried a lot of things to avoid learning how to do it-- ICTs on a 1776, and a horrible AJ Sims "big Kadron" experience.

Jetting assumes you know how to sync the carbs, set the idle mixture, and have a decent linkage. If this stuff is too much, just pay somebody to do it for you. However, I can tell you with 100% certainty that unless your mechanic wants to marry your daughter or something, he'll never spend the time to get it 100% perfect.

If you want to tackle it yourself, this thread is a great place to start. It's 55 pages (and counting), and full of a lot of great information, misinformation, and argument. Still, reading this thread is a great way to start:

55 page carb tuning thread on "the samba"

I've read every post in this thread a couple of times, making me a very sick man, a huge water of time, hopelessly "mad", or all of the above.

To summarize: 14.7: 1 may be "ideal", but 14.7:1 is almost never going to be the best thing for an air-cooled engine.

Why? In a word: heat.

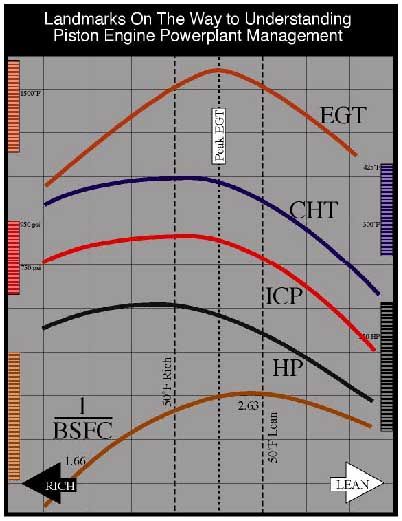

Reference the chart below. This is an aviation chart, where peak EGT (exhaust gas temp) is stoichiometric combustion (14.7:1 A:F ratio). The area to the left of peak EGT (stoich) is rich of peak (or "rich"), represented on an A:F meter as a lower numeric value (10:1, 12.4:1, etc.). The area to the right of EGT is lean of peak (or "lean"), represented on an A:F meter as a higher numeric value (16:1, 15.4:1, etc.),

Aircraft guys tune their mechanical injection system in flight by monitoring EGT, and adjusting accordingly. This is impractical and unworkable in an automotive application, because flying involves a lot of steady-state operation, and cars are constantly getting throttle corrections, etc.

You'll notice that peak power begins at about 100* rich of peak (ROP), peaks at about 75* ROP, and hangs tough until about 50* ROP. You'll notice that the cylinder head temperature (CHT) line roughly follows the HP (horsepower) line. Tuning rich provides a very wide zone in which the engine makes the most power with a lot of fudge factor. This is why drag racers (and everybody else) tunes rich, and why carb sets come with huge jets.

This isn't such a bad way to set main jets- rich of stoich is going to produce the most power.

However, as it was noted above-- running down the road and around town, under the bulk of most driving conditions YOU AREN'T RUNNING ON THE MAIN JETS. You are on the idles. On the idles, I have found it to be better to run slightly to somewhat lean of peak (LOP) than to run rich (as they come set up). If you'll refer to the CHT chart, the temps start to drop off pretty crazily by 50* LOP. HP is also dropping off a lot, but it really doesn't matter because under these conditions the engine is running on the idle jets (barely cracked throttle). Note the bottom line "1/BSFC"-- this represents fuel efficiency. BSFC peaks at 50* LOP.

The net/net of this is as follows: "dyno-tuning" is always at WOT, and great for setting the main jets-- it does nothing for the idle jets, which is where >75% of your time is spent. Tuning a bit lean on idles, at about stoich in transition, and rich on the mains is going to give you the best of everything.

Your A:F meter is going to swing around a lot tuning like this, but once you get a hang of where the transition is occurring (it's vacuum/throttle position dependent-- not RPM dependent), it becomes a lot easier. I get 25- 30 MPG with big carbs on a 2276-2332 set up like this. Power has never been lacking.

In the 55 page thread above, John Connolly advocates hard for tuning crazy-lean (like 16-17:1 lean) on idles. I tried mightily, and suffered a lot of lean misfire in a vain attempt to get to his recommended numbers. My best results have always been to get as lean as I can on the idles before I go into lean misfire, then back to the next size bigger, then "normal" main jet sizes typically recommended by drag racer types (or maybe one leaner). I don't ever mess with emulsion tubes, but fill in any transition issues with accelerator pump squirt. I don't mess with those orifices either-- the "standard" emulsion tubes and accelerator pump jets are good for all but the weirdest applications.

Alternately, you can just set it up to be somewhat ROP everywhere, and it'll make good power as well, but your MPG will not be all that great. It's no big deal if you run 1000 mi/yr, but if you run 5000- 10,000 mi/yr, and you want crisp throttle response and good mileage-- it's worth spending some time on getting it right.

Dude…you lost me at "A guy can spend a lot of time….". ![]() That stuff is way above my pay grade.

That stuff is way above my pay grade.

That being said, all the tech info is spot-on for those in need of that sort of stuff. That's what makes this site the best place for anything and everything about replica Speedsters…there's something in it for everyone whether you need it or not! ![]()

Stan - nice post, and I totally agree with everything, especially that the "normal" 14.7/1 doesn't necessarily apply to an air-cooled engine.

Most of us, however, are "running blind" to CHT and EGT as a measurement to help in tuning our engines and just shotgun things to get us well inside the ballpark. That's where modern Electronic Fuel Injection has is all over us - all of those sensors are included and used by the "Gonculator 5000" ECU all the time.

I tend to run slightly less lean on the Idles, as without a means of measuring the "squirt" of the accelerator pumps I go rich(er) on the idles to make the transition to the mains easier (also with Dells). Either way, (yours or mine) is a workable solution, just approached differently. Everything I've always read on air-cooled VW/Porsche engines, though, tells me to run in the mid-upper 13's as much as I can to keep the engine cooler, so I do.

Which brings up a question - Do you just trial-and-error adjust the accelerator pump strokes or do you use one of those test-tube-measurement thingies that Jimbo has? I set mine years ago and got in the ballpark (somewhere over near Left Field), but it would be nicer to have a more precise way of measuring what's going on with them.

And you're right about the A/F meter swinging around a lot (at least with on-board, constant monitoring), but you get used to seeing what's going on after a short while and can spot a lot of things going wrong as they just begin to happen. Pretty easy to spot a clogged jet versus a manifold leak with an A/F meter if you are used to what it "normally" shows.

Now I'll have to wade through that 55-page Missive.......

Thank you Stan ! It's not often I hear someone speak of Stochiometric values in such a familiar way. Your info is very useful and leads me to being able to "shortcut" some time and effort. I will also scroll thru the Samba stuff you mentioned as well. Again thanks!

Al...I hadn't thought about the vacuum/mechanical distributor application. I may take a closer look at that later,once I get all the other fun stuff I want to do working satisfactorily.

It looks like Sunday will be road test time. Hopefully, I'll have read the Samba info before then..........Bruce

Once again Stan nailed it, in both the info presented and the way it is presented. Kudos!

I also use the snail and an Innovate wideband, which is how I arrived at the only change I needed to make, 57.5 idles instead of the .60s. But my motor was built in 2002 and gasoline was different then so a change was inevitable. Stock emulsions and accelerator jets, 1.40 mains are still spot-on. If I really spent some time I'm sure I could get .55 idles to work. But I get 23 mpg local driving and 32 highway on the way to Carlisle at 70-80 all the way, so I'm thinking it's good.

The problem with that one port is it only ports one cylinder. It may work well depending on the vacuum can on the disti if you grab the port off both carbs and T it together. The best way is to put a fitting in each manifold runner and put them into a small can about 5 cu. in. or so and then run that to the distributor. Only way to do it when running a MAP sensor on EFI or distributorless ignition.

MAP sensors are very sensitive to vacuum fluctuations, disti vacuum cans much less so, but you still need a certain amount of vacuum(and from the correct side of the throttle plate) to operate the vacuum can. The port needs to be located correctly in order to dump or lose the vacuum when under load.

Do not set "target afr" at #'s people are throwing out at random. Engines all like different afr to run correctly. Listen to what the engine wants,for example,a lower compression engine or one with lots of valve overlap will want a richer afr than a higher compression engine or one with mild cams. Also timing advance plays a part in idle/accel/cruising afr's. Every engine is a little different with what it wants,VW aircool engines have a archaic head design and less thermal capacity than watercooled engines and benefit from a little bit richer afr than water cooled gas engines.

I have professionally tuned my own (I say professionally,since I have tuned stand alone on multiple small displacment turbo street engines making over 250bhp per liter) and have idle afr's in the mid 12's,with a mild cam,and WOT set at high 12's,low 13's and cruise in the 13's-low 14's. I do not have a vacuum advance distributor and do not have the timing advance necessary at cruise to take advantage of super lean afr at cruise,which will reduce EGT,but you need the high advance. Listen and FEEL what your car likes!