David,

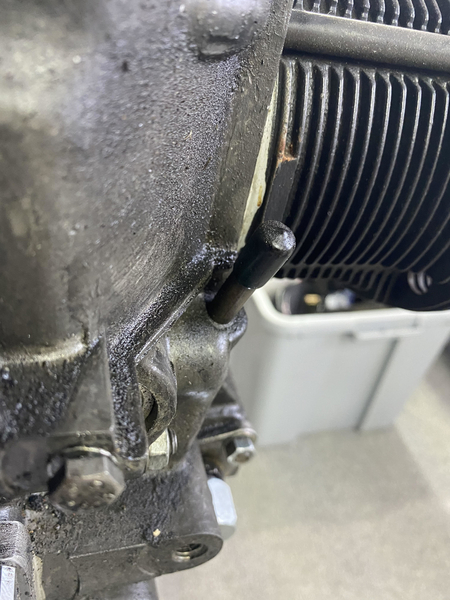

I know that your have a dry sump system-- converted from a wet-sump system, and I'm 99.9% sure that the conversion was done by Ron L. after he had the engine built, installed, and running. That's why there's a dipstick on the engine-- because the dipstick tube was already there, and putting a dipstick in it is a decent way to keep from puking oil out the hole. Here's what I did with mine:

I think I finally understand the confusion. I believe you want to know why there's a level in the sump, as it can't bleed backwards that quickly (it's not overnight, it's "right now").

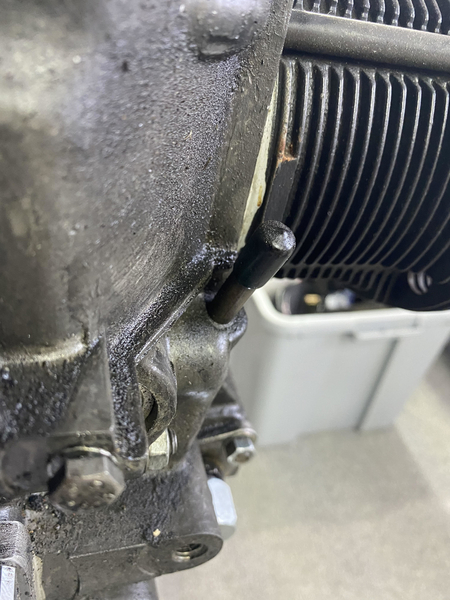

I've got one big question-- does your oil pump look like this?

^^^ A CB dry-sump pump is only about 1-1/2" thick. ^^^

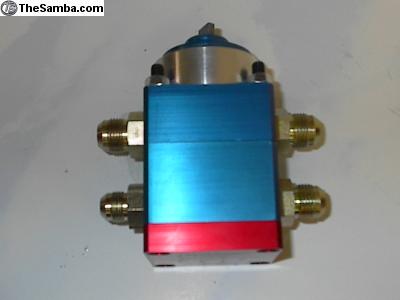

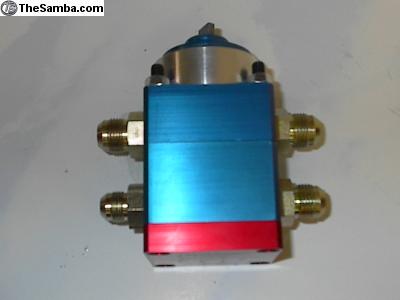

Or does it look more like this:

^^^ An AutoCraft or Buck-Pack pump ^^^ sticks much further away from the case-- like about 3- 4" out to the face of the pump.

The pumps we are talking about are "2-stage" pumps-- they are 2 separate pumps in the same housing*. With both of the pumps above, there is a "scavenge" pump, and a "pressure" pump. The scavenge pump sucks the oil out of the engine and puts it into the reservoir, the pressure pump sucks it out of the reservoir and puts it back in the engine bearings. The oil can be filtered and cooled in either system, but almost everybody (except me) does it in the scavenge circuit.

The scavenge pump will always be bigger than the pressure pump, because the whole goal is to keep the sump dry ("dry sump", get it?).

As you can see from the thickness of the pumps, the impellers on the AutoCraft pump are a lot bigger than those on the CB pump. A LOT bigger.

Why? Well... packaging. The big drawback to a nice, big dry-sump pump is two things

- The crank pulley gets in the way.

- The header collector almost always gets in the way (unless you have a Spyder).

My crank pulley is small enough to clear, but that means it's way smaller than a power pulley even-- small enough that in order for the fan to spin at the right speed, I need a much smaller alternator pulley. That's why I've got a serpentine set-up. Mine was one of the first ones, before everybody was making them-- it was just a guy in his machine shop doing them after work. He (and only he) offered a dry-sump set-up that replicated the stock fan ratio using smaller pulleys that would clear the pump. When everybody in China started copying the systems, he moved on the other things, and the dry-sump pulley set-up became unobtainium.

The other thing is the header, and I had to wait 6 months for Tiger at A1 to build me a custom sidewinder (2 actually, one was 1-3/4" when I had the 2332) that would clear the pump. It was less than awesome trying to do it two time-zones away.

Anyhow-- that's why CB does it the way they do: to allow the use of a 6" power pulley, since the pump doesn't stick out super-far, and the cover plate can sneak behind a 6" pulley, and to allow you to run any exhaust you want. It's slick, except that it may not pump fast enough to keep the crankcase empty of oil.

There's the trade-off. It sounds like yours isn't doing everything it could be doing, and I'd suspect it's because you have a CB pump.

OTOH, it isn't hurting anything either. You aren't carrying any more oil in the crankcase than you would be with a wet-sump, and you are pumping out of the tank. It'll probably run just fine with that, but I'd definitely want an oil pressure gauge in the pressure side of the system to see what kind of oil pressure the pump is producing. I'd guess it's less than you'd think, because the pressure pump on the CB dry-sump pump is pretty small as well. It's hard to fit two nice sized pumps under a pulley.

*FWIW, AutoCraft (and Moroso, and a lot of other people) make multi-stage pumps with many scavenge circuits pulling from a lot of different places (valve-covers, etc.), all dumping back in the reservoir. They're really, really funky looking and are typically belt-driven.

The deeper you go into this stuff, the cooler it gets. Good luck. If you decide to go to a bigger pump, get out your wallet-- it's goes pretty sideways, pretty fast.