.

...I don't know why builders who lay up their own bodies don't modify the molds to accommodate IRS and 5-1/2" wheels. It would just be a matter of pie-cutting a standard rear-end and then splashing a new mold. I know there is time and money involved, but we live in an age of a >$50K base build...

.

Playing advocate for Mr. Beelzebub, here.

If I were a small shop struggling to keep up with orders (and losing the battle), with delivery times slipping two years into the future and up to my Bendpak in alligators, I'd think now wouldn't be the best time to be developing and prototyping new products. (There would probably be no 'Super Coupes' if development hadn't begun long before The Troubles started.)

If anything, what I'd seek is a more streamlined workflow, not diversification, seeing as most folks are happy enough with the current product to be ordering it just as it is.

Too, a lot of customers want these cars because they look just like the originals - the closer the better. Some folks even eschew those hooligan 185/65 tires for skinny 165/80s just because that's what were run in the day.

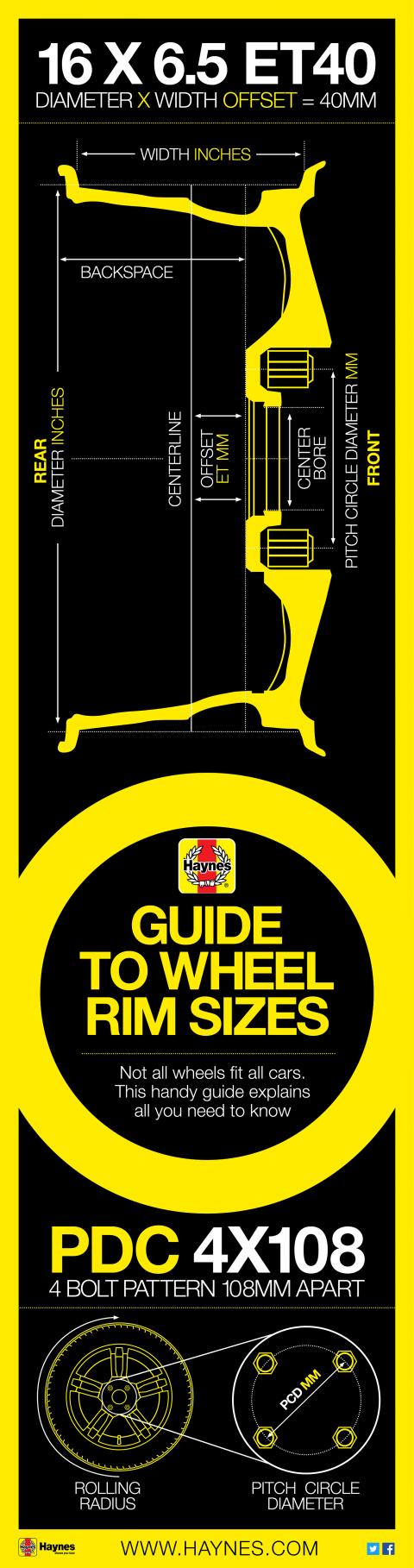

If you're talking small changes for improved performance, accommodating 16- or 17-inch wheels would make sense, too, if only for the wider choice of modern rubber.

If the replica industry survives (it seems pretty healthy just now) and prospers, more options seem likely in the future. Now, maybe not.

And hovering over all of this is the grim fact that no man's life, liberty, or non-compliant clown car are safe while the legislature is in session. With the chance of your current product being regulated out of existence altogether more a possibility each day, I can understand reluctance to throw time and money at new variations.

.