Guys, as always I appreciate all your input.

Al, yes I'd seen that thread - it was one of the first I found when initially googling for fan shrouds. Hence my comment about no vanes inside. It was meant to be a non-partisan comment, just a plain description of the situation.

To my mind that thread is similar to a cross-section of Speedster owners - all the way from those who just want to drive their car regardless of what's under the hood, to super-knowledgeable, technical experts who want the absolute maximum from their engine and/or the perfect engineering solution. I stand somewhere in the middle. I can learn from and appreciate the technical expertise in analysing the problem and going to huge efforts to make things work perfectly, and to be honest the techie geek part of me really loves reading this stuff (I try and bore my wife silly with this new-found info, but for some reason she sticks her fingers in her ears, goes blah blah blah and walks away!), but also I realise that:

a) my driving, wile spirited at times, will never put this car under extreme strain

b) I live in England, so cooling is not so critical as in hotter climates and

c) my engineering skills are minimal.

And whilst I would rather put everything back to stock cooling, that is a level of spend I'd rather not do on a 'learning' vehicle. This is part of the deal with myself on my first Speedster - spend where necessary, learn as much as possible but don't go for perfection.

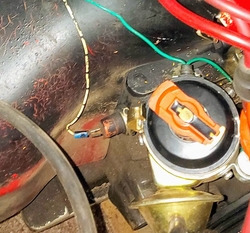

So Danny, I'll follow your lead to a large extent and look to fabricate some kind of simple internal deflector to redirect some of the air towards no. 2 and particularly no. 4 cylinder. As you know, the fan casing has deflector vanes already cast into the rear to cause a swirl effect. I'll also look to fabricate some sled tins, because I appreciate the aerodynamics of the whole situation.

And I stand corrected, in double-checking the securing straps they are indeed stainless steel. :-) And the crossbar/hexbar carb control doesn't fit in a Speedster with a 911-style shroud, hence the twist pullrod fabrication that sits behind the shroud (looking from the rear bumper).

However, I will be working on the 80/20 rule - it's relatively simple to achieve 80% improvement but the final 20% takes ever increasing effort/money (which I won't be doing). But I do plan to seal the hell out of the engine bay to maximise the effectiveness of the fan.

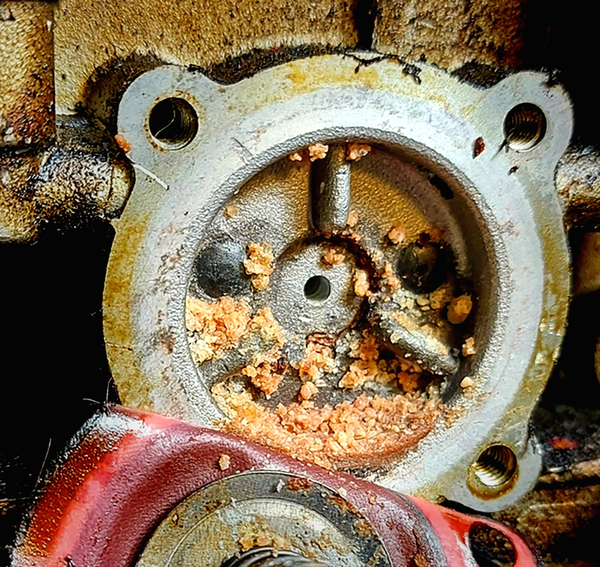

Meanwhile, I'll be sanding down the shroud, getting the dremel out to make the carb manifolds fit properly, checking threads of manifold studs (some are a bit cross-threaded) and figuring out how I can tidy the engine bay. I'll also run a compression test whilst it's easy to do so. One thing I noticed was the non-standard dipstick/oil temp sensor: it doesn't seat properly at the top of the dipstick tube, there's around a 5mm gap, which I think has been letting oil spray out.

Thanks again, and tune in soon for the next episode of Mothy's Garage Adventures!