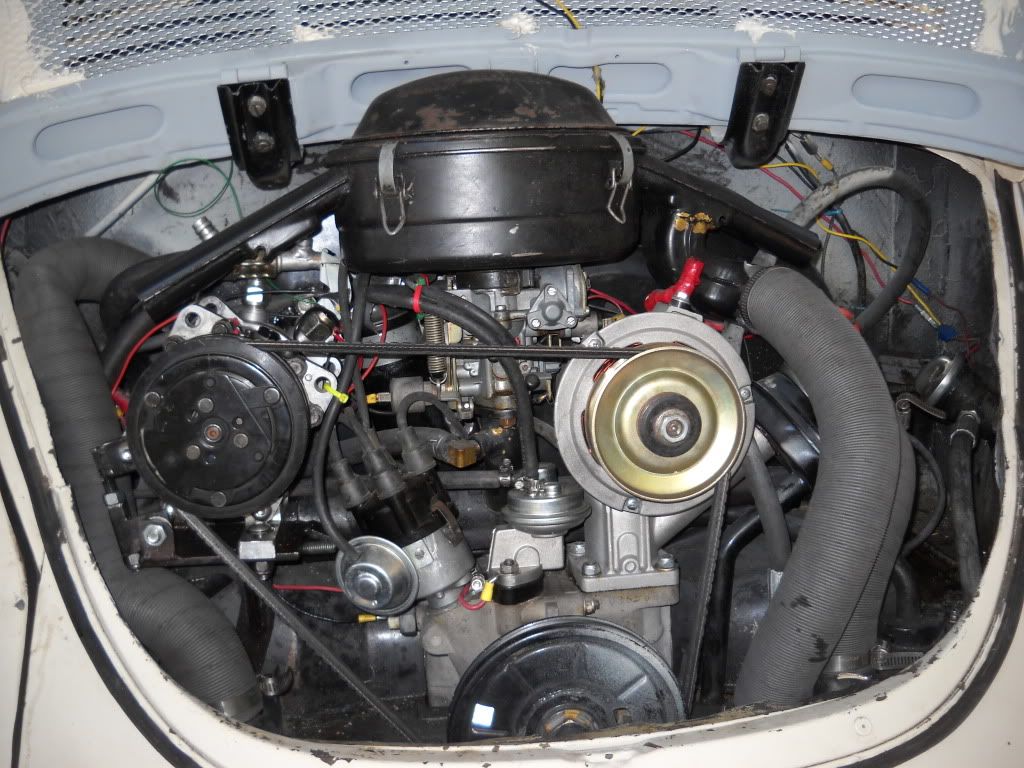

My Beck Speedster has a CB 1915 motor with air-conditioning. So in front of the degreed crank pulley there's another small pulley for the compressor.

I've been hearing this ratty noise for a while and thought it was maybe the fan out of balance and maybe hitting the shroud. Today I took it for a short ride and it was really making more noise. When I got home I looked inside and man I saw the Crank Pulley and the compressor pulley were wobbling bad. By hand it is really loose!

Problem number one is of course the back tins will need to come out to get any kind of socket on the nut.

Problem number two (I think the bigger one) the nut that's on it is some large chrome, larger then the std. nut. (not sure of the size. Also it looks like it has only about an 1/8" or so of contact area to tighten. I could only see inside the compressor pulley with a mirror as it's recessed.

The other minor problem with my Beck is the rubber sealing/gasket material they used to mate to the rear tins to the FG was riveted in place so I'll need to drill all 8 of those out to get the tins out.

Anyone ever deal with a loose not to std. crank pulley nut? If I am able to tighten it what's the torque (like 250+)?

Do you recommend lock tight?

Of course this has to happen right before Carlisle.![]() Then again better at home then on the road.

Then again better at home then on the road.

Thanks for any help.

Pete