Is there such a thing as too much crankcase breathing? Could one use large diameter pipes to a large central box? Any advantage in this? or is some pressure in the case desirable?

Replies sorted oldest to newest

I hope there is not a problem with too much breathing.

I have two breather boxes. I have a CB alternator stand mounted breather box with an added connection to the fuel pump block off and connections to the air cleaners

I also have an EMPI breather box mounted up high on the front of the firewall. I have a vent line from my Berg-5 and my valve covers connected to it.

I have a CB Performance breather mounted on the alternator stand so it "breathes" up through the stand, just like the original VW and the same as the Berg breather. Originally, I had 7/16" ID hoses, one to each air filter to vent the case, and a 3/8" drain hose going to the fuel pump block-off plate to drain back into the sump. It worked OK, but I was still getting quite a bit of pressure, shown by oil being blown out around the crankshaft behind the fan belt pulley. Bear in mind that the Sainted VW Designers engineered it that way to keep any dust/debris from getting sucked IN past the crank, so some positive crankcase pressure is desirable, just not too much.

Over time and by trial-and-error, I deleted the 3/8" drain hose as it wasn't needed (the system drains any oil right back down the oil filler pedestal), added a "Chore Boy" stainless steel scrubber pad inside of the breather box to trap airborne oil being vented, upped the air filter hose ID from 7/16" to 5/8" and that got me down to an acceptable amount of pressure - around town it get almost nothing leaking out behind the pulley. If I'm beating on it on the freeways at 70 - 80-ish all afternoon then I get maybe 4 - 6 drops on the floor after I stop. That amounts to about 1/4 to 1/2 quart per year. I figured that's acceptable. Your mileage may vary.

I too added a pot scrubber to the CB breather. Originally I had a tee on the back of the breather connected to AN6 hoses boing to the air cleaners. I changed those to AN10 with individual connections at the breather, one on the back, and one on the top. I had to drill and tap the breather for the bigger fittings.

I have a Berg clone on my alternator stand with one outlet going to an Empi box and the other outlet piped to the ground. I took my carbs out of the loop. The Empi box other inlets are fed by the valve covers. No leaks , fingers crossed, my carbs run smoother with no crankcase feed.

@R Thorpe posted:No leaks , fingers crossed, my carbs run smoother with no crankcase feed.

That’s what I figured. I lost my air filter input and run a 5/8” hose from my fuel pump block off and a 1/2” hose from my oil filler neck to a catch can filled with ChoreGirls vented to below the car with a 1/2” hose.

I get a few drips from my valve covers occasionally, but none from the pulley area. The catch can has a sight glass on it and after running it for two years, oil has never appeared in the sight glass.

Attachments

@Michael McKelvey posted:I hope there is not a problem with too much breathing.

I have two breather boxes. I have a CB alternator stand mounted breather box with an added connection to the fuel pump block off and connections to the air cleaners

I also have an EMPI breather box mounted up high on the front of the firewall. I have a vent line from my Berg-5 and my valve covers connected to it.

I wouldn't do that. Do you want 90w and engine vapors to mix?

Robert M, you motor looks SWEET!

Originally, only the transmission vented to the box on the front of the firewall.

Then, when I decided to vent the valve covers this was an easier place to connect them.

Do you think this will result in trans oil in my engine and engine oil in my transmission?

If so, maybe I need to add another breather on the firewall to separate them.

I would just put a small breather filter on the transmission itself.

You don't need anything else on it for a street car. The stock VW is a vent hole. My PBS cable shifter has a hole with a brass screen.

Originally, the Berg-5 had a single vent in the nose. Then, the builder said I should add a second one above the R&P. So, I have two trans. lines connecting to the breather box.

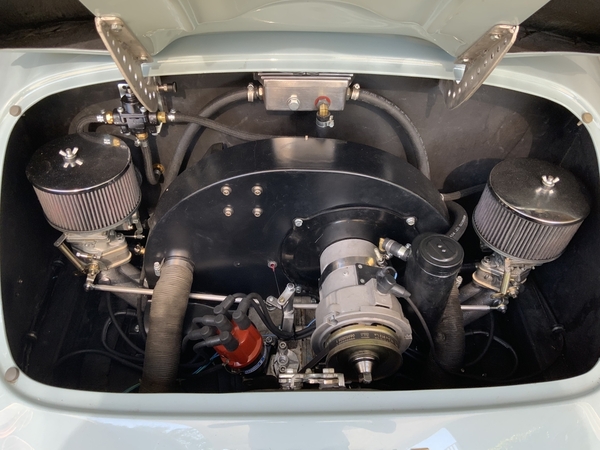

Berg Breather Box and a Kaddie 356 Breather Tower

Crankcase Vented at the Mechanical Fuel Pump Port with a 10AN Fitting

Passenger side Valve Cover Vented

@Michael McKelvey posted:Originally, the Berg-5 had a single vent in the nose. Then, the builder said I should add a second one above the R&P. So, I have two trans. lines connecting to the breather box.

Yes, Michael, although I can't see there being enough intermixing to be an issue, and with the drain going back to the engine you'd only have to worry about diluting the engine oil, what I'd worry more about is the constantly changing engine vacuum pulling oil out of the trans. Is it possible- I don't know, but I think you're still better off to keep the 2 (engine and trans) systems separate. Al

PS- how are you doing? Are you getting out in your car much? Did you get your shifting issue figured out? And btw- the suggestion to add another breather line above the r&p originally came from GBE.

@Michael McKelvey posted:Originally, the Berg-5 had a single vent in the nose. Then, the builder said I should add a second one above the R&P. So, I have two trans. lines connecting to the breather box.

IMO with the fifth gear the vent of is used to prevent frothing and the vent and catch can being high allows the tranny oil to go up if and when it is thrown up towards the catch can and as the tranny settles down the oil goes back down into the tranny. This would not happen with a vent right on the tranny and could end up leaking and you could end up running out of tranny gear oil and get a full STOP Tranny seize up. FYI I have lived this.

In conclusion, you should seperate the two for sure as the mix would not be good in your tranny at all IMO

FWIW it would be nice to have a berg tranny apart to see if the fifth in the nose cone gets affected by oil starvations and if discolouration occurs on 5th showing oil starvation and overheating

So far so good, my engine is a 2332 long stroke and creates lots of crank pressure, with the pictured setup it’s dry so far.

@IaM-Ray posted:...FWIW it would be nice to have a berg tranny apart to see if the fifth in the nose cone gets affected by oil starvations and if discolouration occurs on 5th showing oil starvation and overheating

Berg did send out a notice some time after the original run (they sold about 700(?) of the first design with the modified stock gear holder casting)- iIrc, some holes and grooves to get more oil to the shafts(?), so there was something going on.

@dlearl476 posted:That’s ingenious, Robert, and looks the business. How does it vent?

Same with yours R.

Like I said, I ran a 1/2” hose from the top of my catch can down through the bodywork behind the firewall outside the spring plate. (But my Spyder is backasswards, obviously.)

One of the hoses runs from the oil filler tube to the top of the oil filter canister and a second hose runs out the bottom of the canister back into the case. The lid was modified so there is a little bit of standoff to relieve the pressure or allow fresh air in, whatever it does. Lol

@Robert M posted:One of the hoses runs from the oil filler tube to the top of the oil filter canister and a second hose runs out the bottom of the canister back into the case. The lid was modified so there is a little bit of standoff to relieve the pressure or allow fresh air in, whatever it does. Lol

You don't find it mists your engine compartment with oil?

That's why I ditched my air cleaner input. At the end of the summer, my driver's side carb throttles would be covered in oil.

@dlearl476 posted:You don't find it mists your engine compartment with oil?

That's why I ditched my air cleaner input. At the end of the summer, my driver's side carb throttles would be covered in oil.

Not at all. There’s material inside to help catch the mist. I’ll see if I can remember to open it and take a picture.

I wanted to get rid of hoses so I drilled two holes in the back of my breather box and installed two 1/4" X 4" pipe nipples. These go thru the firewall and the hoses from the valve covers connect back there. I made a little breather housing out of aluminum that has a small, replaceable paper filter in it and attached this to the fan stand. This really cleaned up the clutter in the engine compartment. See photo...............Bruce

Attachments

I did something similar with my electronic ignition.

I ran the wires from it through the firewall and then back into the engine compartment at the coil.

Attachments

Nice, I noticed you have a proper fan housing, are you running an external cooler?

@aircooled posted:I wanted to get rid of hoses so I drilled two holes in the back of my breather box and installed two 1/4" X 4" pipe nipples. These go thru the firewall and the hoses from the valve covers connect back there. I made a little breather housing out of aluminum that has a small, replaceable paper filter in it and attached this to the fan stand. This really cleaned up the clutter in the engine compartment. See photo...............Bruce

Very nice bruce. Your work is ALWAYS meticulous.

@R Thorpe, yes, I have an external oil cooler mounted behind the left rear wheel.

Thorpe....Yes, same as Michael McKelvey, left rear wheel well..............Bruce