The company thats building my Speedster does not supply the Porsche emblems for the car. The emblems are redily avaliable but I'm thinking before I drill the holes I beter know exactly where to drill. Are there templates avaliable to align the emblems? "PORSCHE" on the front "PORSCHE below the engine lid, and the emblem on the dashboard. Thanks.

Replies sorted oldest to newest

I got a template for locating all the "jewelry" on my Spyder from Fibersteel when I purchased the front jackpoints.

I wonder if anything like that is available for a Speedster? Or maybe a kind soul on this site will help you out.

I do have a tip for you though. The Porsche emblem has to be drilled EXACTLY perfect. And you only get one chance. Make a template by poking the posts through a manila folder and tracing the letters. Then you can position it and mark and drill the holes. Step WAY back and eyeball it really long and hard for straight and even.

Cover the area with blue masking tape before you mark the holes. Start your holes with a small bit in REVERSE. This prevents the paint from wanting to lift. Peel the tape toward the holes without pulling the edge of the paint up. Seal the edges of the drilled holes with some touch-up paint or you can raid the wife's clear nail polish. It's important to seal the raw fiberglass.

Thank you, great advise maybe someone has the templates or at least the measurements. Cheers.

Richard

@DannyP posted:I do have a tip for you though. The Porsche emblem has to be drilled EXACTLY perfect. And you only get one chance. Make a template by poking the posts through a manila folder and tracing the letters. Then you can position it and mark and drill the holes. Step WAY back and eyeball it really long and hard for straight and even.

Cover the area with blue masking tape before you mark the holes. Start your holes with a small bit in REVERSE. This prevents the paint from wanting to lift. Peel the tape toward the holes without pulling the edge of the paint up. Seal the edges of the drilled holes with some touch-up paint or you can raid the wife's clear nail polish. It's important to seal the raw fiberglass.

No pressure, though. ![]()

I won't bore you with the sad story of me quietly sobbing after I'd drilled and nutserted holes in my brand new $400 Thing shroud to mount my coil, only to discover it was 3/4" to high to clear my hex bar. Oh, wait.

Good tip on the sealing of the holes. I need to go back and seal the holes I drilled in my front bulkhead for my master cylinder reservoirs and lines.

@Gordon Nichols posted:

Maybe it's just me, but I think I'd rather do it wrong than install it off center.

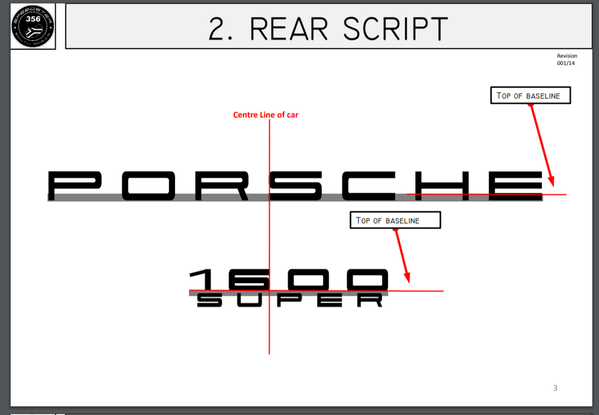

Attachments

Agree 200%, center them.

I want to add that the front nose Porsche and same on the rear the script pins do not go straight into the fiberglass, making the drilling template you need to also allow for the inboard angle of the pins as the script followed the curve of the body.

Alan,

Good point, the hole guide will have to conform to the curvature of the front, maybe carved wood or a strip of soft metal.

I used a piece of clear acrylic about the size of a 12" ruler. Easy to see where the emblem pins are from the back side to mark them for drilling through the clear stuff and then the acrylic becomes the drilling template for the body.

I would grind off the posts and use 3M tape to secure them ... some day you might want to remove them. I had scripts on my first IM but on my newer one I don't have any at all.

I strongly second IaM-Ray’s suggestion: I purchased my emblems from Stoddard’s, carefully ground off the posts with a Drexel, and affixed everything with emblem adhesive. The pieces that needed to contour to the shape of the car (the ‘PORSCHE’ on the nose, for example), I pre bent to match the contour - bending it over a basketball works great, and results in the perfect radius.

My big concern also was that since the our fiberglass is far thicker than the bodywork of the original metal cars, I would have to grind (thin out) the fiberglass from behind each emblem or the pins would otherwise be too short. That thought almost made me more nervous than drilling the holes correctly to start with.

Its been a couple years now and the emblems look as good as the day they went on!

Thanks for all the knowledge, grinding and adhesive looks like the way to go.

I also clip the posts pins off , grind them even with a small cut off wheel or Dremel. Use 3M adhesive emblem tape.

a drilled hole is forever

I would take May West's advice, oh I mean 30west and I never thought about the back side of the FGlass that would scare me too but the permanence of the emblems I did not like on my first IM. Just saying.

@barncobob posted:a drilled hole is forever

Exactly. Grow a set and put the holes in.

X5 on the 3M molding - emblem tape recommendation. It’s easy to grind off the post from the emblems... with tape there are always second chances!

@barncobob posted:a drilled hole is forever

My brother was having a yard sale and among the booty was a hand drill that our family had as long as I can remember. It's going to be the perfect thing for drilling the fiberglass, if I have any more holes to drill.

Maybe.

Is it variable speed?

The preferred method is to use a newly sharpened drill with almost no downforce on it and running at a very low drill speed (150 rpm or so) til you cut gently athrough the gel coat, then speed up a little and slowly cut through the fabric layers. This will minimize cracking or chipping of the gel coat.

Of course, if you use adhesive, this is probably moot.

If you choose adhesive would one use tape or the brush on contact cement made for emblem mounting. What is preferred?

@R Thorpe posted:If you choose adhesive would one use tape or the brush on contact cement made for emblem mounting. What is preferred?

The adhesive is a tape that is applied to the back of the emblem. Others can tell you how they did it. Otherwise you can order emblems with the tape precut.

@R Thorpe posted:If you choose adhesive would one use tape or the brush on contact cement made for emblem mounting. What is preferred?

I would go with tape. Those can be removed with dental floss and GoofOff adhesive remover. If you use emblem adhesive, it can pull the paint off if you have to remove it. I don't know if contact cement would stand up to the elements.

FWIW, here's a little trick from my days of applying 6" Vinyl graphics to sailboats: Spray a little windex on the paint surface, then the adhesive won't immediately stick to the surface. Let's you make adjustments. Once everything is on straight, apply a little pressure then walk away. Once the windex evaporates, the letter will be fixed.

You don't need to cover the entire emblem with the 3 M tape, just both ends and a few other places. I snip larger pieces from the tape roll stick it to the emblem then with a new razor blade make your trim cuts.

Thank you, great tip.

Using emblem tape just makes the most sense. Unless you want the the emblems to look legit from the back side, which, what kind of obsessive knucklehead would ever care about that?

I might add that NOTHING about a replica makes sense. Except that smile that you get when you drive one well. And you're sweaty. And tired.

It's like a good hike to the top of a mountain, or any of a number of other pursuits. When done right, it feels right.

When I ordered my car from Kirk in 2004 I sent him the emblems and the guys in the shop mocked them up and drilled the mounting holes in the body; then they mailed me back the emblems for me to install on the car when it got delivered.

Impala,

I asked just that. Not possible.

That document that Gord shared is great; you could tackle it with adhesive tape. I used 3M plastic emblem adhesive but it is a little tricky.

Yes I think tape is the way to go