Surprise surprise, yes, another question. If anyone's paying attn, clearly I'm juggling a bunch of projects in parallel.

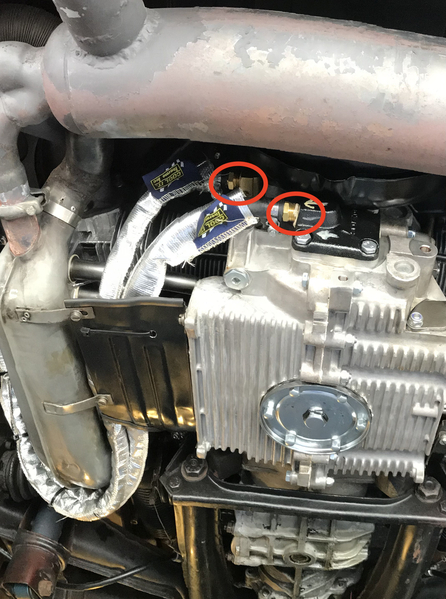

The good news is that I've identified a (maybe the last?) source of leaking oil. Great. The bad news is that I can't get to the location. So I'm just staring at the culprits who're just smugly staring back at me. More specifically, they're metal fittings that simply need teflon tape. I did the same teflon application for a leak around my oil sender and it worked like a charm (yes I was careful about not electrically insulating the relevant portion).

Anyway, these guys are the offenders:

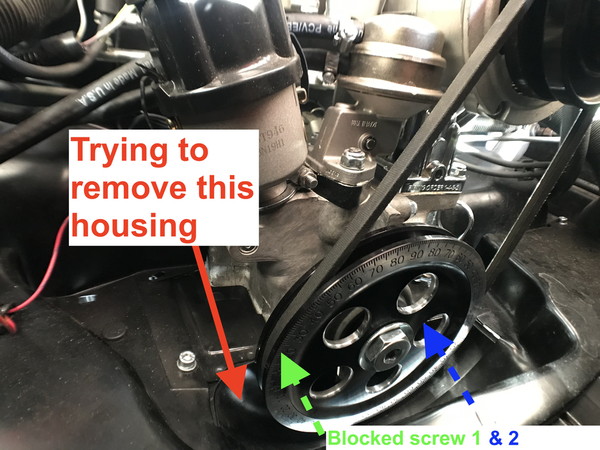

Last time I tried, I can't remember exactly why but I was pretty sure I had to remove this housing (red). Basically that scoop portion that bellies downward to accommodate the pulley wheel. However, there are two screws that're blocked by the pulley wheel itself. The second screw (blue) I can get to through the cross drilled holes of the pulley wheel, but the first one (green) is offset from the cross drilled, unfortunately. So I had to give up, but I'm having trouble ignoring the leak especially when I know exactly where it's from...

SO, my question is what's required to remove this pulley, thereby allowing me to get to that screw? Does it come out easily or require force? Do I need a wheel puller? If so, there isn't much room in there to operate it right? Am I walking right into a world of pain?

As always, any thoughts from you guys are very appreciated