Some of you know I went ahead and did the Hoover mods when I had the 1776 apart to clean it up from sitting new for 12 years.

All I can say is that I've had no oiling or cooling problems since (aside from that time the fan decided to explode). My breath is fresher and checkout girls frequently wink at me at the grocery (that might be because I often forget to zip up).

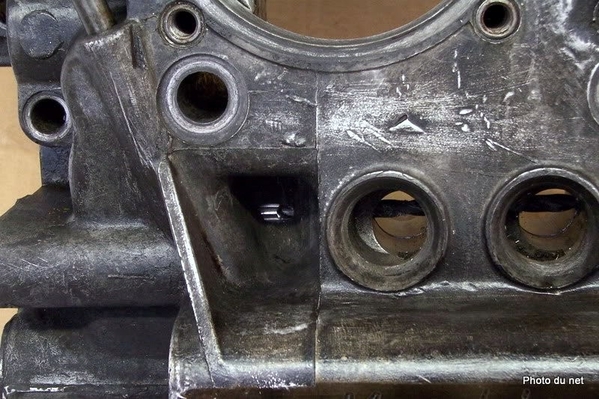

What does that mean? Bob Hoover developed his mods based on teardowns of type 1 engines used to propel aircraft. Having an engine failure at 10,000 ft above the ground is different than having to coast to the side of the road.

I'm convinced most of his mods are based on research and make sense, but may not make a lot of difference for the majority of us. I'm retired and enjoy tweaking things so...

Hypothesis: Hoover mods provide oil flow to critical areas of the type 1 engine and prevent wear, cool better than the stock design. They fail less frequently.

Null Hypothesis: They don't. Hoover mod engines fail at the same or increased rate as unmodified engines.

Rejecting the Null Hypothesis: Data should show that Hoover mod engines fail less frequently and upon teardown analysis show less wear than unmodified engines.

Evidence: Bob Hoover anecdotally said it worked. My engine is still working after 10,000 miles. Replication - haha.

Conclusion: We don't have enough data to reject the null hypothesis. Maybe it helps and maybe not. We just don't have the data to form a conclusion. So, maybe yes, maybe no.

And, as my dear old research professor taught us to say, "Never argue from a non-rejected null hypothesis."