I agree, the casting could be made a little smaller in the area of the flange. I do recommend a thick washer under those small nuts to spread the load and prevent galling the manifolds.

Ok, got that off of my chest, again, and @Stan Galat, I don't want to hear "No, we all use the even SMALLER special nuts!"

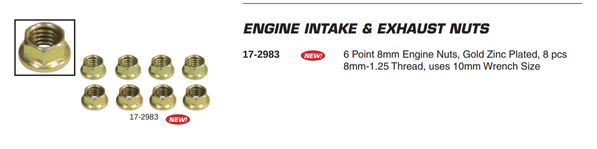

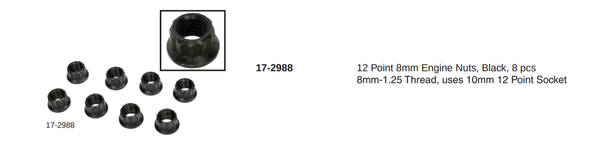

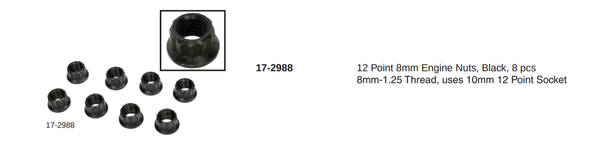

Actually... I didn't post before, because you said you didn't want to hear it, but everything can be solved with different nuts. Smaller socket, no need for a separate washer to drop into the nether regions of your engine when trying to remove the manifolds when you do this again.

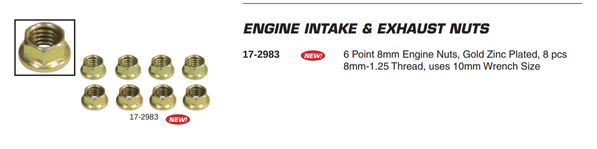

From the EMPI catalog:

or:

They can be purchased almost anywhere that sells EMPI stuff (which is to say, every single VW shop).

Sorry...

PS: The manifolds are always going to be as big as they can possibly be, because they don't cast separate manifolds for every port configuration. The manifolds for the Panchitos are the same casting as those for Super-Pros or Ultra Wedge-Ports, which get a LOT of material cut away inside the runner when port-matched. Lots of hand-porting guys end up welding material onto manifolds, so they can cut the ports even bigger. Your casting is as big as it is to reduce the need for that. It's not a flaw or a QC problem, it's making one part that works for all applications, rather than 15 for each individual port. CB doesn't do everything right, but this is not one of the top 10 "wrong" things.

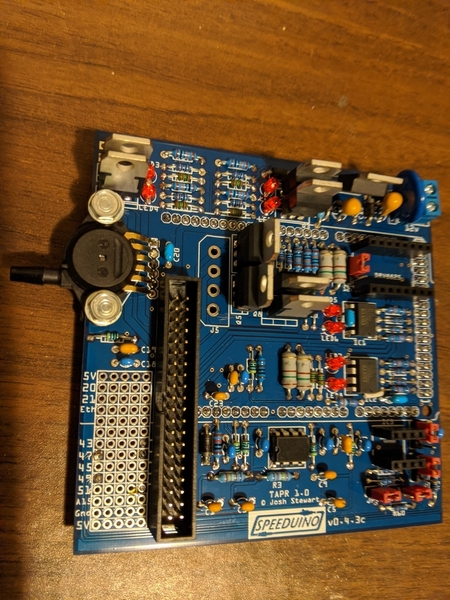

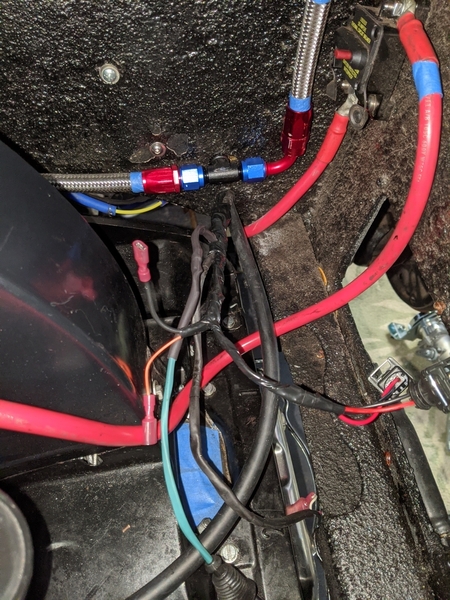

Grinding a bit on the outside of the manifold so we can use 13 mm (or 11mm, as the case is) headed nuts and a 3/8" drive socket instead of aftermarket 10 mm headed nuts and a 1/4" drive socket doesn't seem (to me) like an excessive amount of modification, especially for a guy building an entire EFI/crank-fire system from scratch.

I know it's frustrating, but there is a reason for it.