Was headed out one evening, last week, only to find that my Speedster was a daytime only ride. So I ordered a headlight switch and naturally the new switch is too short to to attach to the dash as the dash if about 1/4" thick. Needless to say I need another switch with a longer nipple. Can someone provide a part number that will work ? I guess all Speedsters would have the same issue. This is the old switch. the threaded nipple is 17mm long.

Replies sorted oldest to newest

Just grind out the fiberglass behind the dash - the fiberlass does not need to be a full 1/4" - 1/8" is fine. You can also look for one in a marine supply store - more expensive but mostly more brass construction.

Grind out the back side of the dash ever so slowly ..I did that same thing on a red oak wood dash that took me 4 days to make and finish only to have me destroy it in 5 seconds when I plunged bit through the new dash :~(

That switch is pretty universal. If you take it out and wander over to your local NAPA store (or equivalent) I'm pretty sure they'll have one with a longer snout. If you need a NAPA cognizant part number, I can probably find something in my "Standard" or "Echlin" catalogs, but they should be able to help you right at the counter.

If not, then you can do the reverse-dash grinding that Wolfie mentioned. I use a Dremel with a 3/16" metal rasp and gently buzz out half the thickness and a circle wide enough to accept the switch body, (If necessary). There is a Dremel accessory that screws onto the tool body that lets you set the depth of the cutting tool so you won't go through - that's handy to have, too, and prevents what happened to Alan.

I would try for the different switch, first. After all, if Steele could find one and not have to cut the backside of the dash, you can too.

I thought about cutting out the back, but there's not much room to work. It would sure make a mess in the car. Sounds like a common problem. Has no one tried to find a switch? They come from somewhere, but have no marks of any kind. The new switch has the din numbering and no fuse. Gordon if you would have a look in your archives I'd really appreciate it.

Jim, There are marine switches that have a longer threaded shaft, best to check out a boat place .

Here's one example https://www.ebay.com/itm/NEW-S...rstClass!26241!US!-1

Jim, you did try replacing the fuse, right? Sometimes the wire separates at one of the ends, so the fuse looks good at first glance. Or the clips can corrode slightly and lose contact with the fuse.

Alan, Thanks. I'm sure your photo is just an example. My switch has 6 terminals and all are used. I'd really like to find a German switch with the DIN numbering. I've sent an email to JPS. I have contacted them in the past and got no response. What's the definition of insanity?

Sacto, The fuse was good. Part of the switch was working. I took it apart and the contacts were all corroded and burnt.

I may be grinding this afternoon. Hate the thought.

You may want to add a relay to the circuit. (Especially the headlight/brights circuit). Corroded / burned contacts indicate the switch can't handle the draw on the circuit.

Safety Jim Buffalo NY. posted:You may want to add a relay to the circuit. (Especially the headlight/brights circuit). Corroded / burned contacts indicate the switch can't handle the draw on the circuit.

There is a lighting relay.

That one in the photo doesn't look like anything German I've seen, and if you opt for a VW German one you'll still have the issue behind the dash as those all expect to go into a 19 gauge piece of metal.

You have what appears to be the equivalent of a Standard Auto Parts DS-121 (which is made for 6 volts). That might 'splain the pitted/corroded contacts inside.

Standard also makes a 12 volt version DS-135.

Either is a "universal" switch, not specific to any make/model. Both have that fuse on the back, although the 6V version should have a slightly larger fuse (like a 20 amp).

For sure, NAPA can look those up and see if they either have one or can get one. They may have dimensional specs on-line, too.

Gordon, DS-135 does appear to be the switch JPS used. Thanks.

Naturally I have cut off the the screw terminals and installed female spades to the wiring harness.

The switch is $14 delivered

I really wanted a DIN switch and have conceived a solution...I'll keep you posted.

Got a reply from JPS. The switch is a DORMAN, PN 85989. Cost 4.99 at O'Reilly Auto Parts. I'll have one by 7:30 in the morning.

Price beats eBay!

Jim Gilbert - Madison, Mississippi posted:Safety Jim Buffalo NY. posted:You may want to add a relay to the circuit. (Especially the headlight/brights circuit). Corroded / burned contacts indicate the switch can't handle the draw on the circuit.

There is a lighting relay.

Jim (Gilbert), all of our cars have at least one dimmer (or 'dipping') relay, which switches the output of the headlight switch between high and low beams.

But, if that's the only relay in your headlight circuit, the heavy current for those lights is still being handled by the switch itself, which is what burns out the contacts. At least two additional relays are needed to route that current around the switch (one relay each for high and low beams).

Basically, the output of the dimmer relay is used to control those two other relays instead of going straight to the lights.

Also, a '6-volt' switch is, in theory, preferable to a '12-volt' switch, as it will (in the best of all possible worlds) have more robust contacts than the 12-volt switch. (Insert long, tedious explanation of voltage, current, and power here.)

If this is Greek to you, do some research here or shout out for some help.

- Mitch

Sacto, I hear what you say.

Based on the wiring diagrams I have, VW did not have a dimmer relay until 1966 and did not have any other relay in the lighting circuit through 1975. That's as far as I looked.

No doubt, best practice might be to install SPST relays on both the hi and lo beams, but VW didn't find them necessary.

I suspect that the corrosion comes from the fact that the switches are not sealed and water gets in there. Corroded contacts burn. Mine were not destroyed, just corroded up and blackened. If I exercised the switch I could make the lights come on. I did drive this car 700 miles home, in a thunderstorm all the way, in 2017.

My car was built in 2009 and now has 15k miles.

The headlight switch is rated at 30 amps; same rating as the relays. VW built 20 million bugs at least several million without additional relays.

If the headlight switches are prone to fail or if the wiring harness burn because of the switch, then I'll install the relays. Please advise me if that is the case.

I don't recall this being an issue in the 60's

Thanks,

Jim - You'll note too that every old VW you see on the road looks like it has dim yellow burning candles for headlamps. VW made a high quality switch but skimped on both wire size to the headlights and the lack of a relay - to save a few production Deutsch Marks. With heavier wiring and relays you'd get full voltage to the headlights (and be able to safely upgraded to whiter light H4 ones) for stronger headlights.

Wolfgang, Are you replacing all of the wiring in the headlight circuit? If not how does this help? The lights are minimal to be sure. I'd like to have better lights.

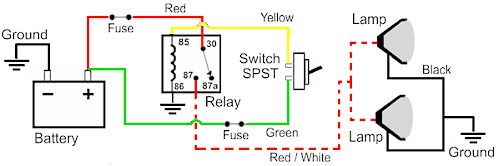

The wiring to the switch is fine since the switch is just used to provide voltage "to pull in" the relays. Heavier wiring is added from the battery to the relay (#30) and then the hot side of the relay to headlights (#87). Since most have the battery in frunk distance is short (a plus). Be sure to also add an inline fuse. While there I added a battery cutoff switch to prevent battery drain and act as cheap theft detection. I used Hella Vision plus "European" lamps with the removable bulbs (Amazon and others have). There are even more modern LED and HID lights available now but $$$. Here generic wiring diagram -

Jim, you're right. VW ran the headlight current right through the switch and never included relays, mainly (as @WOLFGANG says) to save money.

The problem for us is that it's nearly impossible to find a high-quality switch with beefy contacts made out of real brass like VW used. You can track down some original VW switches or high-quality equivalents if you do some sleuthing, but you'll usually pay mightily for them.

Anything you find in an O'Reilly's, Autozone, NAPA, or on Amazon for a friendly price will look spiffy on the outside, but on the inside where it counts, are only diaphanous slivers of pot metal and alloys that disintegrate when exposed to daylight, air, or heavy breathing.

The normal use of a switch oxidizes the contact points just a tad every time the switch is thrown. This oxidation goes up exponentially as the current through the switch increases. Using relays on a headlight circuit cuts down the current through the switch by a factor of around a thousand, allowing you to get a decent service life out of even a cheapo switch.

The headlight switch on my VS burned out after about the tenth time I turned the headlights on. I was worried about finding a decent replacement that would also accept the knob and bezel that matched the other switches. So, I had VS send me the same switch, but I wired in relays. Six years later, the ersatz switch and I are still happy.

Cheers!

more questions...

What gauge wire?

If LED lights are installed does this really need to be done?

I have a primary disconnect.

I hate the cheesy wiring harness on these cars! All of the dash wiring is junk. 14ga wire to a 3 watt bulb is B.S. In my Spyder, I cut the harness at the the feeds to the dash and built a neat little dash harness that was color coded, actually worked and you could see what every wire was connected to. The 10ga primary wire was the only ones not in the harness. It was all about the size of my little finger. I may have to do that again.

For the first time, since I've owned the car, the alternator light actually came on prior to starting the engine. I have never had instrument lights in the oil temp/fuel gauge. I'll get it all fixed and then someone will get a reliable go anywhere car they won't have to work on.

I've got a friend that wants to buy it, but I tell him, not yet, I haven't spent enough money on it.

I'd go at least 14 gauge for 50-65w bulbs - 12 gauge if you plan to use the higher 60-80w bulbs. Bigger is always better - but stiffer and a little more cost.

Here's some pictures of a Speedster with a burned up dash from the switch overheating and catching fire.

Attachments

An alternative to the relays might be LED headlights that draw less power.

Michael, That was one f the questions I asked. It would seem logical that LED's would draw less current. If I start cutting this wiring out I won't be able to find a place to stop.

True - if you want LEDs. With suggested upgrade, the original wiring stays - just cut the 3 prong plug off the back of existing light and pull wire into the frunk. Hook it to relays so it activates the relay then run the heavier wire to the 3 prong plug from the relays and ground. Since the battery is right there in nose, it really isn't much wire to run.

Wolfgang, If I go to LED's and if they draw less current; why would I need to change ANY of the wiring? Why would I need to add relays?

If your wiring is in good shape and each filament is getting 12.5+ VDC then LEDs wouldn't tax the wiring. I'm old school and prefer the look of H4 lights - very European (LEDs are very bright up close and a much whiter/bluer color). H4 is like 4 amp draw and LED 1.5 amp - there is heat with LEDs though.

@ WOLFGANG I sent you a PM

Formula for power(in watts):

P=V×I. V is voltage. I is current

60 watts= 12 x 5, or 6 x 10.

If the wattage of the bulb is the same, twice as much current is drawn through a 6 volt switch at 6 volts. So theoretically a 6 volt switch is designed to handle twice the current a 12 volt one does.

I got an old VW 6 volt headlight switch, and I run LED headlights with no relays. They are bright as heck. 14 gauge wire is good for 15 amps. I might be running 3 amps.

Mitch is right.