Here is a copy of all those parts taken from some manual. Reliable assembly of all related parts was giving me fits and I got plenty of tips from Al Gallo ( thanks again, Al...) and studied that Aussie lad on Youtube till I was blue in the face. He and others will harp on how important it is to not let the large O ring get even a bit dis-logged upon final assembly. The pisser is you won't know if it became dis-logged until you finish the job, fill the tranny up with oil and go for a ride and take a look see for a leak.

I used a different strategy which was WAY easier and I think it will preclude any chance of the large O ring becoming dis-logged. Here's my method. Get everything squeaky clean, lubed up where necessary, then assemble in this order.

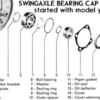

Get the backing plate organized in the correct location, install the inner spacer on the axle, followed by the bearing, then the small washer, then the small O ring. Then take the bearing retainer / cap and install the oil slinger, the seal, the outer spacer into the seal and then the large O ring and finally the gasket. Don't even think about putting the large O ring onto the axle end where it may become dis -logged. Put it in the cap where it cannot become out of position and where it will wind up anyway. Pre-assemble as much as you can into the bearing cap. Easy and it works.

I found that the backing plate would want to spring away from the axle tube a bit because of the springiness of the brake line so a helper would be nice right then to keep it perfectly in place while you slide on the bearing cap assembly. I didn't have a helper and it came out ok anyway because you can hold the backing plate with one hand and just slide on the "pre-assembled" bearing cap on easily with the other hand.