Ted, you're doing a fine job transforming your Speedster. What's it ben since you joined the madness? 12 months or so?

Thanks Rich & Teby.

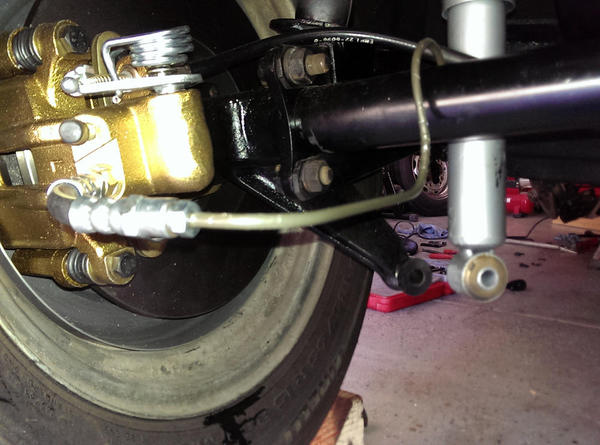

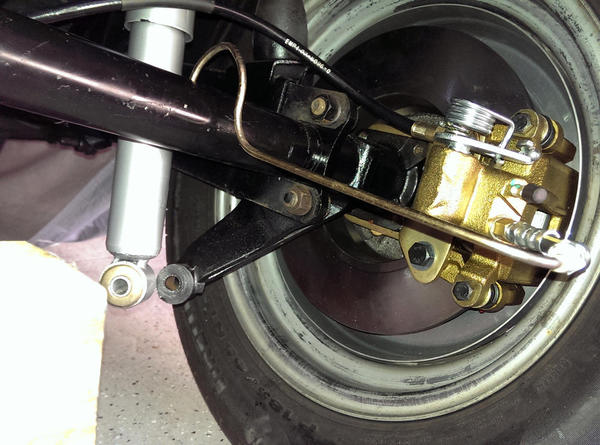

I picked up the car in late March of 2014. Almost nothing I've done 'had to be' done. I just kind of went 'mad' with upgrades. I was thinking about it this morning, I've done a LOT of work on the car. For a change, most of it was mechanical and not cosmetic. ![]() With past cars it was always paint and interior... with mechanical items only as necessary. It's amazing what age does to you.

With past cars it was always paint and interior... with mechanical items only as necessary. It's amazing what age does to you. ![]()

Teby - Heaters are for skinny people. ![]() I don't have heater boxes or any sort of forced air heat. I may put in seat heaters eventually, but for now - I bundle up.

I don't have heater boxes or any sort of forced air heat. I may put in seat heaters eventually, but for now - I bundle up.

Good point on the engine compartment. I'll keep at it. Need to remind myself that it doesn't NEED to be on the road. I'd just like for it to be. ![]()

The rest of you need to get out there and drive.

Greg - if I can almost totally rebuild the mechanicals of my car in less than a year, you should be able to get yours on the road. Yes... that's right... I called you out AGAIN. ![]()

Ted