Isn't cutting a window in the tunnel opposite the pedals going to weaken the chassis?

Doesn’t seem to.

It’s only something like 4” high by 8” long.

edsnova posted:Isn't cutting a window in the tunnel opposite the pedals going to weaken the chassis?

Not at all. In fact, most VW based Speedsters have a cut there (at least all of Kirk’s and now Greg’s). Most of the time they will put a plate over it, but you can still remove it if needed...

ALB posted:*LongFella posted:AllnuttS posted:Brian,

I see you notched the back above the shift coupler. Wasn't there a 2x2 steel horizontal tube running across there in the coupe?

Stephen

There is a 2x2, but it is not that far into the interior. I notch that spot, add a hinge, and stop so that I can access the coupler later on (if needed). I do that same where the opening is on the opposite side of the pedal assembly...

Do you have (or can you take) a good pic of that, Brian? I have that issue with my car and before the trans goes back in I'd like to do something there. I have an adjustable coupler on the end of the shift rod and getting that all undone to pull the trans out was a bear. I have an idea for a solution but it involves welding so I'd like to see what you did. Thanks in advance. Al

Here are some pics. There’s a good amount of distance between my cut out and where the 2x2 is. The foam is nice because it expands and gets all the way back there. It’s easy to shape too...

Attachments

What brand foam are you using, being white?

Attachments

Thanks Brian... Great stuff is off-white to yellow. Hadn't used loctite brand. Plan on cutting my access hatch tomorrow. How deep is your notch?

Brian, is the body standing many inches away from the frame. I have never seen this close up, having never had a pan speedster. Is any cushioning needed or do you just fill it hoping it will never move at all?

Brian 1 or 2 cans to do the rear area?

Alan Merklin posted:Brian 1 or 2 cans to do the rear area?

2 cans, but one can do it. I usually over do it and just trim away the over do...

IaM-Ray posted:Brian, is the body standing many inches away from the frame. I have never seen this close up, having never had a pan speedster. Is any cushioning needed or do you just fill it hoping it will never move at all?

Cushioning? Not sure what you mean??

If sealing... I can only speak for the two of mine I've built/building, but there is (in some areas) a gap that requires some sealant. Not all pans are the same. The body and sub-frame within are usually the same... they just don't line up 100% to the pan... because the pans are all different in some shape or form...

I personally make it a point to seal the sh^& out of every spot the body meets the pan... and then use dyno-mat type stuff to seal and sound deaden it more... and then add some polyester material to sound deaden it even more... and some expanding foam... and more sound deadening material...

All of that adds weight too ![]()

Which, of course demands the application of additional horsepower to mitigate. 🏎

Ray: The original VW had a body/pan sealing gasket that, in cross section, looked like a small dog bone, maybe 1-1/2" wide. It was very effective, but as Brian mentioned, there are a lot of differences between the donor pan mating surface and the speedster body frame causing gaps here and there needing something extra - The VW body and pan fit together really closely, the speedster frames, not so much.

Before we had the benefit of this forum, I assembled one car without that gasket, using only LOTS of silicon caulk instead, followed a few years later with lots of foam (Great Stuff) to finally seal things up. After the forum, the next car got a base of silicon, then that dogbone gasket followed by another thick layer of silicon and then mating the body and THEN followed with more foam (Great Stuff). Unfortunately, Dr. Clock finished that car so I don't know how effective all that work was (and all those tubes and tubes of silicon caulk).

I simply installed a sump pump! ;-)

That's pro'bly a much simpler approach......

And maybe baffles in the footwells to keep the fore and aft tidal waves at bay!

Gordon Nichols posted:Ray: The original VW had a body/pan sealing gasket that, in cross section, looked like a small dog bone, maybe 1-1/2" wide. It was very effective, but as Brian mentioned, there are a lot of differences between the donor pan mating surface and the speedster body frame causing gaps here and there needing something extra - The VW body and pan fit together really closely, the speedster frames, not so much.

Before we had the benefit of this forum, I assembled one car without that gasket, using only LOTS of silicon caulk instead, followed a few years later with lots of foam (Great Stuff) to finally seal things up. After the forum, the next car got a base of silicon, then that dogbone gasket followed by another thick layer of silicon and then mating the body and THEN followed with more foam (Great Stuff). Unfortunately, Dr. Clock finished that car so I don't know how effective all that work was (and all those tubes and tubes of silicon caulk).

The gasket helps, but there will almost always be a little gap.

Here is the stuff I use on all the seams inside and out...

Attachments

Thanks for the info having never built one from scratch it’s good to know the challenges

Lane Anderson posted:Which, of course demands the application of additional horsepower to mitigate. 🏎

Yes it does!

Attachments

Brian, looking good, I would double the insulation and sound deadening in your coupe to reduce the reverberation that these can bring. Just saying. Since it's christmas you can use flashy christmas wraps. ![]()

Attachments

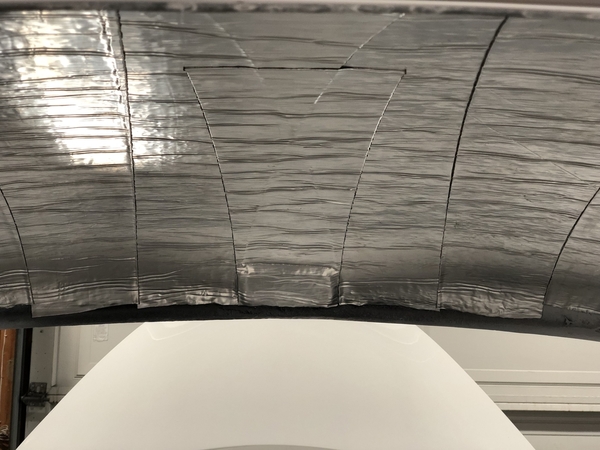

Now for the second coat and absolute silence in that coupe....![]()

Brian, your making me think about how to get one of those across the border ![]()

IaM-Ray posted:Now for the second coat and absolute silence in that coupe....

That would be a little much. There will be carpet padding and German square weave carpet on top... should be enough ![]()

IaM-Ray posted:BTW, there is a Bug restorator in NJ that uses roofing tar paper to sound insulate all his cars and he says it does a great job, does not smell and is very inexpensive.

I think it is this

That’s similar to what I’m using. I think mine is called Peal and Seal. Cheap at Lowe’s and works perfectly. Thickness is good too and it doesn’t smell at all...

Attachments

@*LongFella I used the same stuff after I took out my carpet to put in the subwoofer. I heated mine with a heat gun and used a roller to really make the stuff stick. I'm sure I don't have to tel you how to do this since this is your second car.

Robert M posted:@*LongFella I used the same stuff after I took out my carpet to put in the subwoofer. I heated mine with a heat gun and used a roller to really make the stuff stick. I'm sure I don't have to tel you how to do this since this is your second car.

The heat gun is essential, especially when doing the roof or up under the dash.

But damn the heat gun tip gets hot - got a little love bit’s from it today...

@*LongFella Beautiful work. I'm still working on the body of mine and you and the rest of the folks here are giving me great info. Thanks and hope you have a great holiday season.

*LongFella posted:Robert M posted:@*LongFella I used the same stuff after I took out my carpet to put in the subwoofer. I heated mine with a heat gun and used a roller to really make the stuff stick. I'm sure I don't have to tel you how to do this since this is your second car.

The heat gun is essential, especially when doing the roof or up under the dash.

But damn the heat gun tip gets hot - got a little love bit’s from it today...

I'm not gonna ask how bad it was...

*LongFella posted:IaM-Ray posted:BTW, there is a Bug restorator in NJ that uses roofing tar paper to sound insulate all his cars and he says it does a great job, does not smell and is very inexpensive.

I think it is this

That’s similar to what I’m using. I think mine is called Peal and Seal. Cheap at Lowe’s and works perfectly. Thickness is good too and it doesn’t smell at all...

Will this roof stuff work equally as well in say, the door cavities?

thanks,

Art

Art posted:*LongFella posted:IaM-Ray posted:BTW, there is a Bug restorator in NJ that uses roofing tar paper to sound insulate all his cars and he says it does a great job, does not smell and is very inexpensive.

I think it is this

That’s similar to what I’m using. I think mine is called Peal and Seal. Cheap at Lowe’s and works perfectly. Thickness is good too and it doesn’t smell at all...

Will this roof stuff work equally as well in say, the door cavities?

thanks,

Art

Yes. The key to install is using a heat gun. You need to heat the base enough so that it becomes slightly soft. Use a paint roller to press it in. Done.

I did the roof of my coupe a few days ago and you can’t get it off...

Heat gun. One must use a heat gun ![]()

Art posted:*LongFella posted:IaM-Ray posted:BTW, there is a Bug restorator in NJ that uses roofing tar paper to sound insulate all his cars and he says it does a great job, does not smell and is very inexpensive.

I think it is this

That’s similar to what I’m using. I think mine is called Peal and Seal. Cheap at Lowe’s and works perfectly. Thickness is good too and it doesn’t smell at all...

Will this roof stuff work equally as well in say, the door cavities?

thanks,

Art

I have it in my doors and it works well. As stated above, use a heat gun to soften it up. Sticks like the dickens after that.

Updates from over the holidays...

99.9% of sound deadening is done. Only spot left is inside the doors and will take 10 mins to do. Next step: complete underside coating of truck bed liner (same stuff I used for the pan). The underside has already been sealed.

After the above is complete: run the wiring harness, gauges, lights, battery, gas tank, emblems, etc... shouldn't take too long since I've done it all before...

Then off to the upholster. Rather then get the carpet kit like I did the Speedster, I am having the kit cut/fit specifically to the car... should turn out a lot nicer...

Once that is done... off to Greg for the glass to be put in...

I am really hoping this all done before SLO so my wifey has something to drive too ![]()