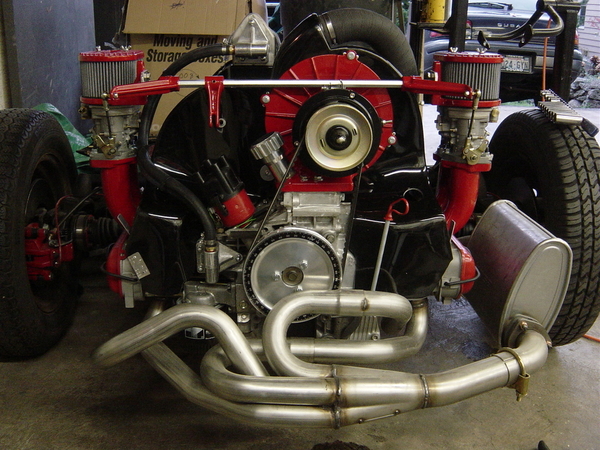

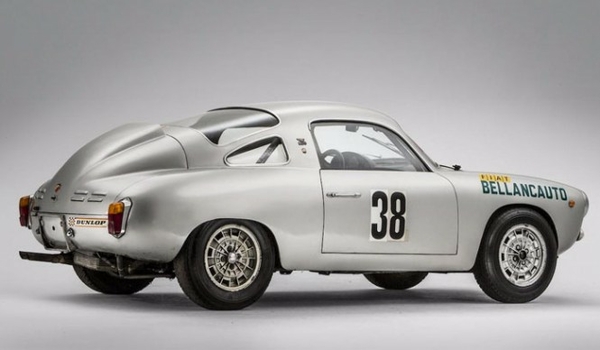

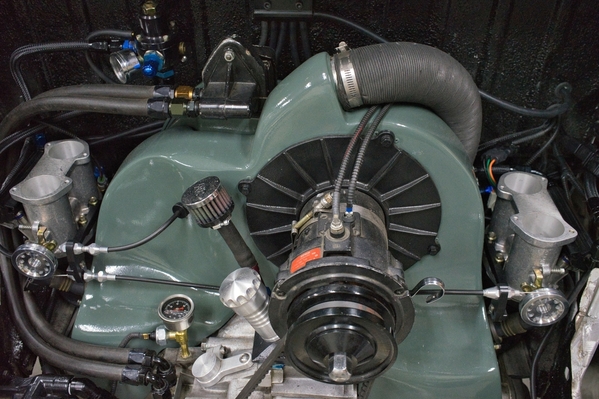

I decided it best to start a new thread to post the progress of the big type 4 engine I am having built. To recap I bought a used turnkey Raby parts kit 2056 type 4 engine from a fellow SOC member and Speedster owner Chris Sutton. I have given the engine to my engine builder Bill Westerfeld, a long time Porsche, VW engine builder in the Cincinnati, Oh. area. He has been in the go fast business for over 40 years. I have had several engines built by him and have only praise for his big talent and attention to detail he gives each and every engine he builds. Bill, has his own machine shop and can do just about anything including head work from mild to wild . That said I picked up Chris's engine because it was too good a deal to pass up and a no brainer. If I was looking to just make a profit I could doubled my investment by parting the engine out, instead I have decided to build a larger displacement type 4 and then install it in my recently bought Puma. The engine builder ordered the parts today, 104mm P&C's, 82mm Counter weighted forged crank shaft, H beam connecting rods, Webcam 86a cam with 1" circle to allow crank clearance (The cam specs are .435" lobe lift (.565" lift with with the 1.3 ratio rockers) .290 duration) along with all the other items needed to build an engine with all new parts. The displacement will be 2786cc and the HP/TQ target is 240HP/235 TQ. This will be more clearly known once I decide on the amount of head work I want to have done. That said, does anyone know anything about the AA or AMC stage 2 914 heads offered by AA? I can't find any feedback online concerning the quality of the heads which appear to be nice for the money. The Raby modified 1.8L heads that came with the motor are very nice also and I will have a bunch of porting work done if I go with them. I will have the valve sizes increased from 42/36 to 48/38 as well. If you are new to the Chris Sutton Type 4 engine for sale story I have attached a pic of the engine after it was completed by Chris many years ago to give an idea of what the DTM fan setup looks like. It converts the type 4 engine to an upright fan and allows it to by mounted to a type 1 transaxle. I will be posting more as the engine progresses.

Replies sorted oldest to newest

Hoffmann Automotive Machine (HAM) in Watkinsville, GA has been the go-to for Type 4 heads for a long, long time. Have your guy talk to Len.

That’s gonna be one hell of a sexy looking hot rod, Jimmy. I gotta get a ride in it sometime.

Thanks Stan you sent me to the right place! I may consider ordering a pair of LE200 heads. According to Len Hoffman of Hoffman Automotive they are the most up to date highest performing type 4 head available with ceramic coated valve chambers and Thermobaric coated exteriors, with the highest flow and highest port velocity. They are made by HAM using AA head castings from China. According to his site the Chinese castings have improved since their launch. Hoffman Automotive stopped taking any used type 4 and 914 heads in to rebuild or repair in 2017 because they weren't getting any in that were in goo enough shape to repair. From 2017 forward they have only sold new heads built from first AMC castings (their quality declined) and now AA castings FYI. I love this forum, what a treasure of info and great people.

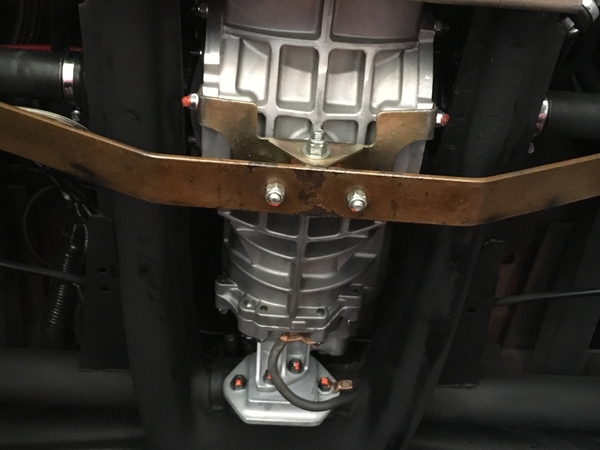

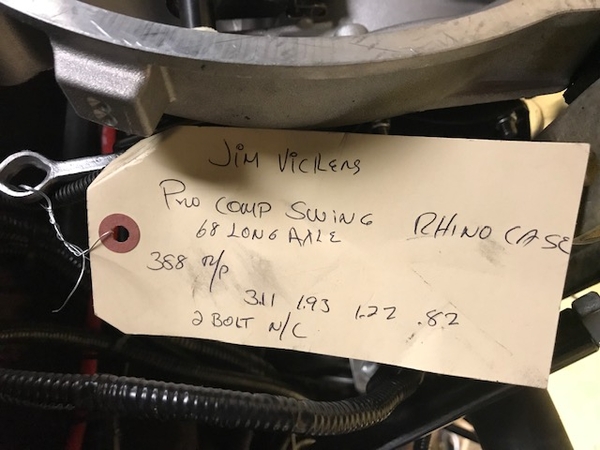

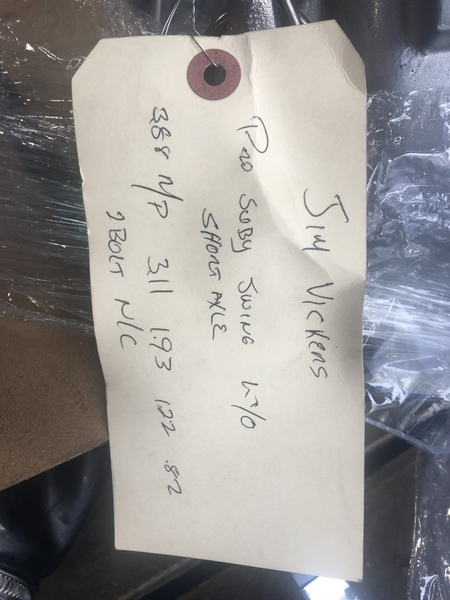

Ok, my engine builder now has all the parts in to build my 2786 Type 4 engine. He has started on the heads, taking them apart and checking everything. He is giving all the valves a competition 3 angle grind and cleaning up and cc'ing the combustion chambers and lastly cutting the heads open to fit the cylinders for the 104mm pistons. He will then install the old bearings on the new 82mm crank and rod assembly and mock it up in the engine block so he can rotate it to find the places that will need to be ground away to make clearance. The new crank, rods pistons,& flywheel will be sent out to be balanced together as a unit. Ask Alan how much this makes a difference in how an engine runs. The 2276 Type 1 that I just sold was balanced like this and it would zip up to 6k no problem and sound great doing it. I haven't trusted many type 1 engines to do this. I estimate that the engine will be finished by the 2nd week in Sept.. I have Rancho building me a Pro Suby transaxle just like the one in my Subaru powered Speedster. Why? the trans in the Puma needs work and it is a stock geared 4.12 R&P unit and I know and like the gear ratio of the Pro Suby unit built in a Rhino case and it will work well with the Type 4 for the time I run it and the Puma will be ready for this winter when Carey converts it to a 2.5L suby engine with heat and A/C. The monster type 4 will be placed on the market for sale. More to come soon.

Attachments

... and so it begins...

Jake told me my valve-train was good to 7500. My crank/rods/pistons/pulley/pressure plate were all dynamically-balanced as a unit. My motor pulls strong and balanced up to 6500, peak power is at 6K though so I usually keep it under that.

But yes, what a glorious sound a well-balanced easy-revving motor makes!

My engine builder sent me some more pics and a video today. The cylinders will need to be cut down to get the correct deck height to make 9.5:1 CR. He has mocked up the crank, cam and connecting rods in the engine block to find out the areas that need to clearance ground. This has been completed, now the crank, pistons rods, flywheel and clutch assembly are all being sent out to be balanced at a shop that builds top fuel drag engines. This shop will also be cutting the cylinders down to the size we need. I am looking at 3-4 weeks before the engine is finished. I can't wait to hear the engine fire up.

Attachments

Just thinking about how, if you fused the crankshafts of two 1300cc Type 1s, the resulting FLAT 8 would still be smaller than this.

David at Rancho just called and they are shipping the Pro Suby Rhino cased transaxle they just finished building for me. It is a twin of the trans in my Speedster. It will work well with the torquey type 4 or a Suby engine if and when I go that route. I love the one I have in my Speedster so ordered one to replace the squealing transaxle currently in the Puma. I should have the engine and Trans ready to go in before the months end.

Attachments

Except for an IRS notation, that looks just like the tag on my transaxle! Greg says I'm in the cue for some big work next week. I'm all tingly.

Hey Michael, is Greg building you a coup? what engine are you running? Is it a Suby? If so you will love the gearing of the rancho Trans. It isn't an inexpensive item but worth every cent. Good luck with the build. Post lot's of pics.

Hi Jimmy!

Yes he is. Link to the thread in this post. Short answer Suby 2.5, Z-head with porting, aftermarket FI (stinger), Rancho Pro-Suby w/Peloquin torsen diff, AirKewld Wilwood 4 pot discs (so I can easily change to 5X130...also not T-bone anything!). Lot's of other stuff (AC, heat defrost) too numerous to list.

I spent a lot of time researching before I designed and then pulled the trigger. Listened to you, Stan, Danny, Alan, Art, Bob, Paul, Troy, Theon....everybody I guess. I had been explaining choices in my last few posts there. I'll continue that soon. Been hellishly busy for a few months.

Here's the link: https://www.speedsterowners.co...a-coupe-build-thread

Michael

The snowball keeps on a rolling. Instead of using the heads that we had with 42/36 valves and stock ports, My engine builder has ordered a set of hot cylinder heads with 48 intake and 38 exhaust, dual valve springs and stage 2 porting with welded up and match ported intake manifolds. The heads will now be more inline with the large displacement of the engine. Now I am thinking of going with 48 IDF carbs instead of the 44's I have. This thing has truly turned into a monster, mores ways than one.

Attachments

Hoffman, yes.

@Jimmy V. posted:Hoffman, yes.

This one will be special. Cam?

I approve of the head/valve/port enlargement. You're going up 40 percent in displacement, after all.

I mean, 2.8 liters is well into what they used to call the "Big Bore Group" back in the early days of sporty cars. It's why you still see 240 Zs racing against five-liter Camaros on Labor Day weekend at Lime Rock.

I am running what I think is a relatively mild cam but the engine builder tells me it is what I want. It is a Webcam 86A it has 290 advertised duration and .435 valve lift with 1.1 ratio rockers( is 1.1 what bus type IV heads have?) the rockers in my heads are 914 type which are 1.3 ratio so that calculates to .514 valve lift ( .435 divided by 1.1 = a .395 lift at the cam multiplied by 1.3 = .514 valve lift.)

@Jimmy V. posted:I am running what I think is a relatively mild cam but the engine builder tells me it is what I want. It is a Webcam 86A it has 290 advertised duration and .435 valve lift with 1.1 ratio rockers( is 1.1 what bus type IV heads have?) the rockers in my heads are 914 type which are 1.3 ratio so that calculates to .514 valve lift ( .435 divided by 1.1 = a .395 lift at the cam multiplied by 1.3 = .514 valve lift.)

Thanks, Jimmy. That is a very mild cam for those heads, but it should be a torque monster with all that displacement. I'll be very curious how you like it.

Aircooled says this cam is .435 lift with 1.3 rockers. I think that is mild, as is the 252 degrees duration at .05. It also says the powerband goes to 6000 rpm, which ... how?

By way of comparison, the Engle W125 in my little 1914 has an advertised lift of .460 with 1.1 rockers and 262 degrees duration at .05 lift. The dyno charts on these engines, as built by Raby with 8.5-1 compression, dual springs & Weber 44s, show peak torque (circa 125 ft-lbs) at 4000 and peak HP (122-ish) at 5500. Raby revved them to 6k on the stand, losing 2-3 hp off peak, before shutting down.

Judging by chatter on the forums, lots of Type 4 players love the Webcam 86A, and I would not challenge the judgment of a real, experienced engine builder, but I am curious to learn how such a small cam would be deemed optimal for such a large engine, as built for such a light vehicle as the Puma.

Raby loved the 86b in Big Type 4s, back when he was sharing information.

I also love my 86b in my type1. Along with the 1.5 rockers(cam designed for 1.4 or 1.5). I've got .575" lift at the valve, which is on the edge of maximum.

Conventional wisdom on a LARGE type4 such as Jimmy's is to cam them up, as they already have major torque built-in.

But at the end of the day, Len Hoffman knows far more than any of us armchair engine designers. I'll bet the motor will be great, as the man who built the heads is the man who knows the best cam for them.

All I can say for sure is that Jimmy is my spirit animal. He’s not shy about going big.

We shall see. I have been assured the 86A is plenty cam with the 290 duration. I want an engine that makes plenty of power and torque in the 1500-5500 range not in the 3500-7500 range. The lower valve lift will make the stress on the valvetrain less. I will have plenty of valve size and cam duration to compensate for the lower lift. The combustion chambers will still fill plenty fast. If I don't like the way it runs with the 48/38 ported heads I will go back to the RAT 42/36 heads and use the big heads on a different build or sell them. My engine builder is the one who is saying the 86a is the cam to give me the end result I have asked for not Len Hoffman.

The bottom end of the engine is together and waiting for the heads to be built. Once the heads arrive the cylinder bottoms will be cut down to give the desired deck height giving 9.5:1 CR. Now to be patient and wait...

Attachments

Jim DuBois’ killer T1 in the silver lightweight outlaw Al Merklin sold a couple of years back was built similarly— huge heads, lots of displacement, and a very small cam (the same one, unless I’m mistaken).

That engine also flew in the face of conventional thinking, and was by all reports a monster.

As an interesting comparison, here is the tag I got with my Engle 120 cam - It's damn close to Jimmy's spec. It sits in a 2,110 that pulls like a train from 1500 to over 5 grand and I'm very happy with it.

Attachments

Oooo.... I have the Mofoco head specs, too. Single HD valve springs (recommended by my solid tappet Hot Rod friends to save my cam lobes) and I'm supposedly running 8:1 C/R.

Attachments

Nice mild combo and it's been going strong for like what? Two decades?

A W120 cammed 2100 with decent heads is the absolute sweet-spot for these cars. They are zero muss-'n-fuss, long lived, cool running perfection. I'd probably run more compression than 8:1, but we're quibbling here.

Yeah, Ed - 20 years from day zero and running better than ever!

Well, it’s 8.3:1 C/R, but not quibbling.

That was because I was asked if I might run 87 octane gas in it. It runs fine with a tank of 87 but I usually run 89 or higher.

But you’re right, Stan - Just hop in and drive it for 20 years with only minor issues.

I'm a little lost. You were on TheSamba yesterday asking about AA Stage 2 48x38 heads. I went to AA's site and saw a picture of the heads you put up a few posts above.

Are you getting AA heads, or Hoffman Automotive Engineering heads? Either way, I'm following this build closely, as the T1 engine you just sold was a masterwork and a screaming value. The cam choice is super-interesting, and I'm waiting anxiously to hear your thoughts about how it runs in your Puma.

Keep posting-- I love this stuff.,

@Gordon Nichols posted:Yeah, Ed - 20 years from day zero and running better than ever!

Well, it’s 8.3:1 C/R, but not quibbling.

That was because I was asked if I might run 87 octane gas in it. It runs fine with a tank of 87 but I usually run 89 or higher.But you’re right, Stan - Just hop in and drive it for 20 years with only minor issues.

I'll never forget your saga of the broken rocker adjuster on your son's wedding day!

Stan: I was wanting to know if anyone has tried the AA heads because according to the Hoffman website their head castings come from AA Performance because the AMC heads starting having quality issues.( I just pulled a pic off of a search of images of type 4 heads that had porting work.) I was curious how the finished heads from AA ran in case we have to wait too long from Hoffman. What I got from Samba was a bunch of advice and criticism I didn't ask for or want and not anyone that answered my simple question. I made myself stop replying and haven't been back. I forget how good we have it here on SOC even with our small issues, it is still much better then most car based forums.

That clears it up! Thanks, @Jimmy V.

Yeah, TheSamba is super-good for picking everything apart.

Dan wrote: "I'll never forget your saga of the broken rocker adjuster on your son's wedding day!"

Yeah, that was epic. How many times do you hear about a rocker arm shaft breaking on a VW T-1? In someone's wedding get-away car? Like almost never, but there you go. Occasional rocker arm, yes, but the shaft? Never.

At least it made it through the off-site photo session before it completely died. His best friend (who now lives in Sandy Eggo and drives some sort of Porsche dual-turbo thing) came back to the hotel after it died with the news and that he was having AAA transport it to the best Man's house, but the main uses for the car were over and as we all know, it's a mechanical thing and mechanical things can be fixed. Fortunately, all of the guys in the wedding party are car guys.

That little drama didn't dampen his car-loving spirit, though. He's still hopelessly in love with cars. And his wife! She has realized (probably early on) that he's just like his nutty father....... ![]()

Wedding Escape car before disaster:

The bride, wondering just what the heck she's getting into (and a rare photo of Chris' sister, Anna, in the front on the left - she was used to the "car Guy" thing):

And the dead Pearl, after the hex was put on her...... That's Will, calling AAA:

Attachments

@Gordon Nichols Without the distracting cars in background.

Attachments

Thanks! Wish I could do that, but my Photoshop abilities are non-existent.

I was excited to received after 6 weeks of waiting a new Rancho rhino case Pro Suby transaxle. After unwrapping the plastic I was disappointed to find they built it with the wrong length axles. I ordered a trans with long axles and they sent short. Upon contacting Rancho they said the would have it picked up and switched to long axles. The trucking company is going to make out on this $700.00 round trip from Indiana to California and and back. I am glad my engine isn't ready or I would be a little more upset. It gives me more time to clean and paint the underside of the Puma.

Attachments

@Jimmy V. Despite detailed descriptions from me and often with photos... for those that can't take the time to read. It has become the standard way things go, this happens to me with build parts more times than you can imagine. I just ordered $6k worth of chassis parts , I'll be picking the parts up in person so I'll see how that turns out.

yikes!

It is amazing how they can be so oblivious to easy in your face details. They also sent the trans to the wrong address. I gave them my business address and they sent it to my home address which cost me $150.00 extra for residential delivery charges they will be paying me back. What a waste. I guess they must be charging way high prices to cover all of the costly mistakes they seem to be ok making.

Yikes squared!

Glad you noticed the incorrect axle lengths. I'd have missed that until installation, probably.

Rancho really came thru and got the trans shipped back and changed the axles the same day it arrived to them and sent it straight back to me all shipping covered as it should be. I have my Pro Suby Rhino cased transaxle with long axles back and will install it Saturday in the Puma. While the engine and trans have been out I have cleaned and painted the under side of the car, wheel wells and engine compartment. It turned out very nice. It was not my favorite type of work but I would have hated myself later if I hadn't done it. I am glad it is done now. My heads are in transit to the engine builder. He will have them Monday. He told me he completely takes apart any new heads and checks everything. He has had new heads from CB come in with tight valve guides and get a stuck valve in the first weeks of service. I am glad he is doing this, I have bought new supposedly high quality heads in the past and have most of the valves not lapped and leaking badly. Bill will completely go through the heads and make sure they are perfect. He then should have the engine finished assembled and running by the week of the 19th. I may get the Puma up and screaming by the months end. I am also in the process of mounting a Derale oil cooler fan assembly with fan thermostat and oil control thermostat. The only place I could get the room and get clean cool air is by mounting the cooler inside the front trunk. I will make a future post showing how I am getting fresh air flow in the trunk. It is similar to how Special Edition mounted my Radiator in the frunk of my FF Speedster Suby conversion. More to come shortly.

Attachments

I now have the Rancho Rhino Case Pro Suby Transaxle installed in the Puma. My heads will arrive tomorrow to the engine builder so my hope is in 2 weeks or less I will be installing the new 2.8L Type 4 in the Puma. I also hope I don't get any leaks at the axle seals. It is always a mystery to me how the crazy assortment of spacers, O rings, seals and paper gaskets work together the keep the oil in the axle tubes. I have extra shims in my setup that must have came with the disc brake conversion to offset the thicker aluminum back plates. It wasn't leaking before the transaxle swap so I hope it works now.

Attachments

Very nice. So the Subaru modified transaxle will work with the type 4? Any estimation on torque and hp with the new motor? I guess since you put that transaxle in you are still planning on going with the Subaru motor in the end?

Here is my thinking. The stock 4.12 geared trans that was in the car needed a rebuild. The bearings were a screaming. The type 4 is going to easily have the power and torque of the Suby engine the trans was geared for. I have one of the same transaxles in my Suby Speedster and love it so it was an easy decision to go with this transaxle. I will run the type 4 in the Puma for awhile and get the carb jetting perfected then sell it off. I will then have Special Edition convert the car to Suby power and have heat and A/C in the car to make it a year round driver. That is my end game but I am really enjoying the fun of trying a couple of engines along the way. This type 4 is going to be a super strong running engine. I have had smaller displacement type 4 's in the 2.5L range that where really powerful power plants, so the 2.8L will be uncharted territory for me. I am mere weeks away for having the type 4 finished. I can't wait. Stay tuned.

PS. The Type 4 's estimated output is going to be well over 200 hp and 180-190 ft lbs of torque. I am planning on doing some tuning on a chassis dyno so I will have the real numbers eventually. I am eager to find out. Thanks for asking.

Jimmy...I am curious to see what HP you put on the ground when you get that far. It should be a screamer !.................Bruce

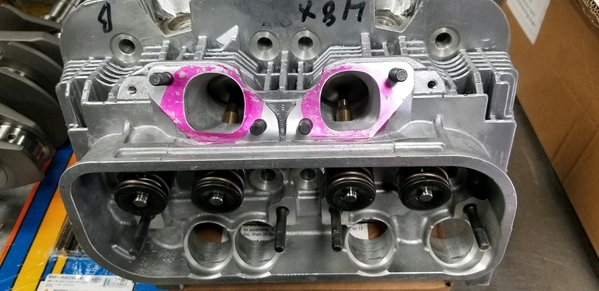

The 48/38 stage 2 ported heads and port matched manifolds have just arrived to my engine builder. He will completely disassemble the heads and check everything and fix anything that doesn't meet his standards. We went with the heads AA offers because of his past experience with the quality, lead time and price. He assures me the heads will be great. I can see the finish line on the monster type 4, it is in sight now.

Attachments

@Jimmy V. After I redid my axle seals I hadn't installed the drums and the axle nuts. After a few days the axles were leaking. i thought I did them wrong so I did them again. Come to find out that the drums and axle nuts were in fact the final component to keep everything from leaking. You may get some leaking if the drums or rotors haven't been installed yet. Otherwise if your seals are in correctly you should be good.

I have the rotors and castle nuts on and torqued to 253 ft lbs. The brake drums or rotors if you have disc brakes compress the assembly and preload the axle bearing so you are correct they will leak if the drum and castle nuts are not installed and torqued down the correct amount. Mine is complete and torqued . I hope I have no leaks.

Jimmy this car with this engine needs to meet a Dino on a dark desert highway.

Yeah. I can’t wait either.

I filled the transaxle with 90Wt gear oil last night. At least I didn't see any oil under the brake rotors this morning. The real test will be in the driving the trans. I hate to work on something I don't completely understand. I don't fully understand how the axle seals and spacers all work to keep the oil in the axle tube, I just followed the directions I found online.

@Jimmy V. posted:I filled the transaxle with 90Wt gear oil last night. At least I didn't see any oil under the brake rotors this morning. The real test will be in the driving the trans. I hate to work on something I don't completely understand. I don't fully understand how the axle seals and spacers all work to keep the oil in the axle tube, I just followed the directions I found online.

“I’ve always depended on the kindness of strangers.” Blanche DuBois - Streetcar Named Desire

To me, transmissions have always been voodoo. I’m sure they’re pretty simple once you understand them, but I’ve always left it to experts.

BTW, Jimmy. I was re-reading this thread and it dawned on my that the original RSR’s had a 2.7 motor in them. That Puma is going to be more of an Ocelot!

Transmissions aren't that hard. Swing axles and seals aren't that hard either.

You need special tools to rebuild. You need a hydraulic press, and lots of sockets/spacers to push with. You need a long pair of heavy duty needle-nose pliers with a little grinding to remove/install the axle circlips in the differential.

You need good instructions as well. You need to do research, and take your time.

Remember, I was told(on here and Facebook) that I'd never get my trans back together and have it work. Whatever. I've had it apart several times after I beat the snot out of it. I've broken synchros, circlips, and a third gear synchro hub.

The engine should be finished by end of next week. The Puma is ready to have the engine slipped into place. I am wondering how the type 4 will compare to the Subaru in my Speedster.

Attachments

The 2.8L Type 4 is nearing completion. As with anything that has been modified my engine builder is finding issues to overcome as he goes. Being an engine with a longer stroke than stock the engine is now wider by almost an inch. Some of the issues he is dealing with include having to lengthen the push rod tubes, as is they were too short and have nothing to hold them in the head or block. He figured something out to space it on the side that goes into the head. Next issue is the DTM fan shroud. The holes for the spark plug access do not line up and will need to be enlarged on one side of each hole and filled in on the other because the heads are further out than they where. The header as it was is too narrow. It will need the spot welds ground off so the extra length can be found in the slip joint areas. Bill the engine builder has assured me that each obstacle can be overcome and made perfect ( I was glad to hear that!). He has also taken apart the rocker arm assemblies and polished the shafts and cleaned everything. The rocker arm geometry was then set using custom length pushrods. The intake gaskets had to be custom shaped to match the ported heads and intakes. The engine is mostly assembled and should be getting fired up for cam break in by the end of the week. I will be buying a new crank pulley and doing some cosmetic work once I have the engine home. I am hoping there is enough height clearance to allow the DTM fan shroud and oil cooler to fit into the Puma's engine compartment. If not I have an alternate plan to use a lower profile version 2 DTM fan shroud and a remote oil cooler. I will hopefully have the engine home sometime next week.

Attachments

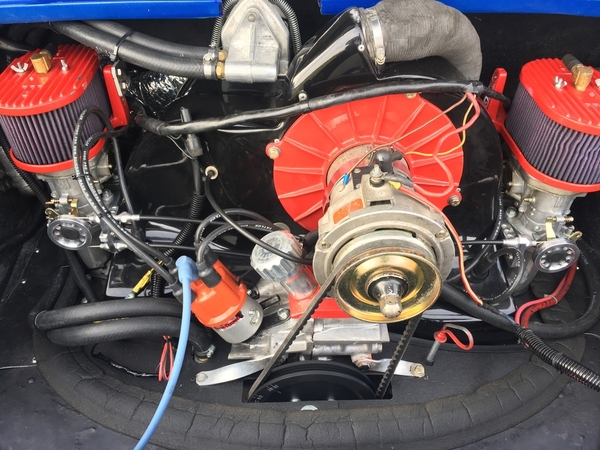

The Monster Type 4 Lives! My engine builder got the engine running and broke the cam in and just sent me a short low quality clip of it running. I think the engine sounds fantastic, tight and smooth. I will be driving the 4 hour round trip tomorrow or Saturday to pick it up. More to come soon.

Attachments

Spins right up, doesn't it!

Yes, that was my thought. I love an engine that revs up and back fast and crisp, formula one style LOL.. My plan is to detail the engine to my taste once I have it instead of having the builder charge me for that. I like doing that part. I plan to pop the engine into the car and drive her a bit and then take the engine back out once winter really sets in to make her more attractive. I am really excited to feel how this engine stacks up in comparison to the 2276 Type 1 that I just sold and the 2.5 Suby engine in my Speedster. I love comparing the different driving experiences. The engine sure sounds nice and tight. The engine should have a nice balance of torque and top end. That was the goal.

I'm guessing a light flywheel in that one, Jimmy. It sounds really good.

Sounds great! It ought to make that Puma really scoot.

The vision of the Puma doing wheel stands just popped into my mind... hmm most of the weight including the battery is in the rear. Take the spare out of the frunk run a 1/2 gal. of fuel. If I had sticky tires who knows. I remember a front cover of Popular Mechanics back in the mid 70's that showed a VW Thing doing a wheel stand as it left a red light. They had an article describing the way the Thing was made with the engine hanging out the back made it easy to pop the clutch and lift the front wheels with a stock Thing. I never forgot that. My minds wonders from time to time.

Arrived home yesterday with the Monster Type 4 after picking it up at the engine builder's and started getting it ready to install. I installed the custom cut aluminum pcs. to surround the engine to seal the engine compartment off from recirculating the hot cooling air. The engine surround pcs. are sold by the type 4 store to work with the DTM fan system. All of the the surround pcs. came with this engine pre build up. I replaced the crank pulley for appearance sake and will clean and paint or replace the valve covers once the engine is installed. I am concerned that I don't have enough over head clearance to fit the tall DTM fan shroud, It is going to be very close and just fit if it does. If it doesn't fit I have a fall back plan to use a version 2 DTM shroud that was made to have a lower profile. Stay tuned. PS I just returned from the auto parts store with FI style hose clamps to replace all the worm gear clamps.

Attachments

Excellent! Let er' rip!

Just curious Jimmy. I remember the original owner mentioning something about one of the cylinders having low compression or a bad crank bearing or something. What did your mechanic find when he pulled it apart?

The engine was in almost as new condition ( the engine had only 4000 miles on it). The crank and rod journals were at new size and didn't need anything but a polish, the cam was in perfect shape, the pistons, rings and cylinders all perfect the cylinders still showed cross hatching. He did find a bent pushrod. If my memory serves I read the previous owner's (Chris Sutton) build blog and he mentioned that after having the engine assembled he cranked the engine over and it locked up. He tore it back down and found the cam was several teeth off from having the dots match up. The top of one piston had a little smile mark where a valve hit it. I assume he bent a push rod then. This may have caused the low compression symptom he was experiencing I don't know. I sold off the crank, rods, heads, cam, lifters and a set of new 96mm P&C's. Which netted me more than the entire engine cost me. Then I spent a ton of money having the engine transformed into the 2.8L monster it is.

The battle is partially won. The monster 2.8 L type 4 is in the engine bay of the Puma and securely bolted to the new Rancho transaxle. I had to remove the already installed engine compartment sealing tin, crank and alternator pulleys and the header to get her to to finally to release and drop into the transaxle. Oh that magical feeling when the engine finally releases and slides into the trans. Taking a break today to recharge. The 11 hour one man battle did me in!

Attachments

Congrats! The anticipation is killing me.

Outstanding! I've done the one man engine removal and installation on my Speedster, although it was just a type 1, and it was not my favorite way to spend a few hours.

Ok, I went to close the hood and it hits the top of the DTM shroud just as I feared. So, I can now pull the engine back out and remove the DTM fan shroud buy a Version 2 DTM and install it along with a remote oil cooler fan assembly and thermostat. Or I can finish the engine install and run it with stand offs of some design that will hold the hood open a few inches, this way I can drive it some while the weather is still nice and pull the engine later this winter to install the V2 DTM. The damn lid is only a few inches from closing. I also had thought of cutting a hole in the hood to allow the top of the DTM to protrude and covering it with a small scoop or turbo bulge but then I would be cutting up the hood. The issue is patience and time. I really would like to drive the car to see how it runs this season so I may go with rigging something to hold the hood open a few inches, it actually doesn't look that bad. I am so close I can taste it.

I would rig it up so I could drive it. Hopefully you won't discover any other issues that could be corrected when you pull the motor again to fix the shroud.

I'm with Bob. Get some drive time on it to see what pops up to fix and/or adjust.

Maybe run without the engine cover?

Attachments

@edsnova posted:Maybe run without the engine cover?

^ That.

I almost fell to the temptation of getting out the sawsall at 3 am Sunday morning while tired and frustrated. I made myself stop and go to bed, a very smart decision. After more looking at what is hitting today I was able to trim away a portion of the inner hood and then get the hood to close with a slight bulge of the hood that could someday be a trend to allow more cooling air in and be a sign to those who know that underneath lurks a monster 2.8L type 4 engine LOL. Kidding aside, It was a relief to discover that I will be able to get this long awaited engine running so I can drive this little beast soon. I hope to have the car on the road by weeks end. I need to tidy the wiring up and get the engine compartment sealed separating the top side from the bottom which as we know is so important to keep our air cooled engines running cool. I also want to get the oil pressure , oil temp and head temp gauges hooked up. I am currently waiting for a new electronic distributor to arrive. The one on the engine now is an old points distributor. The new distributor should arrive no later than Wednesday. I went to buy a Pertronix kit but was told they are out of stock and back ordered with a 3-4 week min. lead time. They did have the complete Pertronix Flame thrower dist. in stock so I bought that.

Attachments

Can you put spacers under the hinge that's attached to the body? I'm afraid that the lid might eventually crack. Something is going to crack. Luckily it wasn't you.

I totally agree with Carlos, that is a crack begging to happen!

I appreciate your concerns but I am going to risk the cracking. I feel it is an acceptable risk to take all things considered. Fiberglass can be repaired and this is far from being a show car. I may have been able to alleviate the bowing by placing spacers under the hinge bases but unfortunately the bases appear to be permanently attached to the Fiberglass. I am going to run it as is to get the engine tested and tuned. On the good side the engine is rigidly mounted and won't be rocking or moving exacerbating the cracking threat. I did need to cut away a portion of the inside lip of the hood opening to make clearance for the top of the oil cooler. I saved the pc. that was cut out for future option of replace and fiberglass repair.

Thanks to all for their interest and encouragement on this journey. It has been fun. I really hope this thing runs like I think it will. If so, it will be a ton of fun. I should have a test drive tomorrow or Thursday. I will keep you all posted.

can U put a tastefully done airscoop there

I hadn't mentioned the update kits that I had installed on the 44 Weber carbs. We were on the fence about moving up to 48 IDF carbs and decided to use the CB Performance Update kit on the 44 Weber carbs I have. The kits remove the auxiliary and main venturi with one larger (38mm) venturi and add a special horizontal spray bar. This allows more air and fuel to flow through the carbs without losing drivability. The kits had been out of stock and came back in stock just a week ago. I had a kit direct shipped to the engine builder. Mark at CB asked me when I was ordering what engine I was using the kits on. I told him a 2.8L type 4 build and he said that this is exactly what they designed this kit to go on. Here is the link the the CB Performance page. https://www.cbperformance.com/product-p/6457.htm

I spent some time tonight getting the engine wired up , headers installed and dropped in the new Pertronix Flame thrower distributor. I fired the engine up for the first time. At this point I don't have provision for a muffler and this thing is loud and sounds mean. If the engine runs half as mean as it sounds then it will be scary fast. I may have created a true monster. If all goes well I hope to take a short drive tomorrow. Next I need to figure out something to quiet this down some. The video my engine builder sent doesn't represent how extremely loud the engine is. The sound it makes when rev'ed is nothing short of amazing.

Attachments

@barncobob posted:can U put a tastefully done airscoop there

Somewhere out there there is a Fiat Abarth with a very tasteful small scoop, but I can't find it. Similar to this, only just about 2"-3" tall and maybe a foot wide. Can't hurt getting more air into that big lump, can it?

Attachments

I am not ignoring the air scoop comments. I had thought the same and may go that direction when I get that far. I am placing that in the fine tuning stage of the project. I have it where the car can be driven so for now that isn't crucial.

I always knew the exhaust system that came with the engine was not going to fit. I saved the A-1 sidewinder muffler and dual exit tail pipe from the header I had on the type 1 engine and thought I could make it work with some fabrication but know now that the header takes up all the space the the tail pipe would have gone. I still may be able to use the A-1 muffler with a single down turn pipe. Once I have the car drivable I will take it down to my buddy who owns a muffler shop. He is a great guy and has worked on my custom jobs for over 25 years. I can also buy one of the small mufflers A-1 offers to go on the end of the header and use a down turn pipe, I have some room in the wheel well for this.

Please don't hack up the car further to make an engine (any engine) fit. A V2 DTM will fit. A Cali conversion with a Puma shroud will fit.

Move Muhammad, not the mountain.

I concur. Great analogy, Stan.

Respectfully, If we all thought like that the hot rod and custom scene born after WWII going forward would never have started. You can choose not to chop up your car, I can do as I please with mine. Anything I do to the Puma can be reversed with some Fiberglass matting and resin. To each his own taste, I say.

It is your car, and a beauty at that. The engine is awesome, but I thought it was just going to be a place holder for the Subaru. Regardless, I meant no offense, and I trust none was taken.

Do as you wish.

Heck no Stan, absolutely no offense taken. I hope my reply was not taken wrong either. Far as the Suby engine, it is on hold for now, I have a feeling the Type 4 has found a home in the Puma for awhile. I will know for sure once I get her on the road but I think the power is going to be intoxicating and make the NA Suby engine seem tame. I can also see now that the Subaru conversion would take some major chopping as well. The engine compartment of the Puma isn't anywhere near as large as the Speedster and it tapers down as you go toward the rear. So talk about chopping the car up, the frunk would be cut up for the radiator and the rear would be a challenge to say the least. Not saying it will never happen but for now the monster Type 4 has a home. Check with me next week and that may change. I don't mind any comments and now have learned the personality of the forum and enjoy the back and forth.

@Jimmy V. posted:Respectfully, If we all thought like that the hot rod and custom scene born after WWII going forward would never have started. You can choose not to chop up your car, I can do as I please with mine. Anything I do to the Puma can be reversed with some Fiberglass matting and resin. To each his own taste, I say.

I was going to say in my post last night that if it were me, I'd remove to engine cover and either make a copy with scoops or have a boat place do it. And keep the original cover as is for when you put the Subie in it (if you end up doing that.)

Personally, I think having the scoop would make it distinctive to reflect the distinctive nature of the motor.

Jimmy V.....I don't know if you have a drag strip close by but it would be nice to see the numbers if you took it to a strip. Also, what it weighs. I will get some numbers on my Suby Spyder when its completed and sourced. (If they ever open up Irwindale Raceway again!) ......Bruce

@Jimmy V. posted:I spent some time tonight getting the engine wired up , headers installed and dropped in the new Pertronix Flame thrower distributor. I fired the engine up for the first time. At this point I don't have provision for a muffler and this thing is loud and sounds mean. If the engine runs half as mean as it sounds then it will be scary fast. I may have created a true monster. If all goes well I hope to take a short drive tomorrow. Next I need to figure out something to quiet this down some. The video my engine builder sent doesn't represent how extremely loud the engine is. The sound it makes when rev'ed is nothing short of amazing.

@Jimmy V. What car is the motor installed in?

It's a VW Puma.

I have been getting all the small details of the engine install lined out. The engine compartment is completely sealed all the way around the engine front and across the back. Zero hot air from under the engine will get recycled into the cooling fan or carb throats. All fresh clean cool air going into the cooling fan and into the carbs as the engine was designed by VW/Porsche. In my experience this makes all the difference between a hot running engine and an engine that runs the correct temp. (You don't want the engine to run too cool either).

I took the Puma for a few test runs last night and today. When I got brave enough and trusted the car today I opened the carbs past half throttle... the engine is all that and a large bag of chips. It gave me the kick in the pants neck snapping acceleration I was looking for and I was no where near full throttle. The engine is amazing and will (measured with my seat of the pants feel) kick my Suby Speedster's ass when it comes to acceleration. This is what I was hoping for, mission accomplished in this area. I am going to have a muffler shop retrofit the chrome A-1 in and out muffler I have left over from my 2276 side winder header. I pushed this muffler onto the header collector and it does the job to quiet the engine and still sound mean. I will make an appointment tomorrow to have the muffler installed. The car will be much more user friendly. The sound and pull this engine has is really amazing as it should be. I was adding up the bills on this engine and I could have bought 2 - Ford 347 turnkey roller engines with aluminum heads and 465HP for what this engine has cost. It may not be practical but boy is it fun. I had three people wave and yell cool car on my short drives. People seem to like the Puma.

Attachments

Beautiful work, Jimmy. I hope to see this beast someday.

I have an appt. tomorrow morning with a muffler shop to install the A-1 muffler that I saved from the sidewinder header I had on the 2276 Type 1 engine. I held the muffler on the end of the type 4's header and it really quieted the beast down. I am hoping the shop has the talent to attach the muffler in a way it can be easily removed to access the rockers on the passenger side head.

I have also ordered a synclink throttle cable set up to replace the cross bar linkage. I don't like the way cross bar is setup and I feel the carbs will never be fully in sync using it. Anyone have experience with the synclink?

Attachments

@Jimmy V. posted:Anyone have experience with the synclink?

I do. I love it.

I’m not sure if the Vintage Speed setup would work with the Type IV you have there Jimmy but that’s what I’m using and it works very well on my Type I. I was going to use the Synclink until Pat Downs suggested the Vintage Speed linkage.

Stan did you buy your sync link from Pete Staszkiw ?

Robert, I considered the vintage Speed linkage but went with the synclink. I am not sure the vintage Speed has a setup for the type 4 and my engine is a little over 1/2" wider than normal as well.

How does the synclink connect between the two carbs? I always wondered if temperature-related expansion contraction would throw things out of sync. If the cable expanded/contracted at a different rate that the engine itself, it would seem inevitable.

.

The synchlink uses a compound cable, like the brake cable on a bicycle (there's an inner cable and a rigid outer metal housing).

The only motion that matters is the inner cable relative to the outer housing. The two ends of the housing can move relative to each other and it doesn't affect how much motion is transferred by the cable.

Despite the photo above, the cable between the two sides doesn't need to be in a perfectly straight line. Kinda like a Bowden tube works.

.

The cables should not get hot enough to make a noticeable difference and they would all expand the same amount. The system looks like it will really work well. I guess I will find out. It has to be better than what I have now. The carb bell crank arm on the drivers side has a 1.5" long rod coming off the linkage at 90 degrees to make the reach. It is what is needed to have synchronized carb opening but it is flimsy and doesn't work well.

@Jimmy V. posted:Stan did you buy your sync link from Pete Staszkiw ?

Yep. I think that's the only way to get one, which is why most builders don't use them.

I am curious, Why would that keep engine builders from buying the kits?

@Jimmy V. posted:I am curious, Why would that keep engine builders from buying the kits?

It's just a guess. But I got the impression that Pete's a dude making these in his spare time. I'm not sure he could or wants to build them in the kind of quantities that builders like Pat would need.

Also, there's the cost of them-- not a lot of people want to give that much for a linkage (although I think they are worth every penny).

So glad you got underway on that carb linkage. I saw that extender bit and was about to ask about it.

"It's just a guess. But I got the impression that Pete's a dude making these in his spare time. I'm not sure he could or wants to build them in the kind of quantities that builders like Pat would need."

Reminds me of Mike Kitteridge, the founder of Yankee Candle. He built his business up with a couple of friends and eventually sold it for $500 Million. After that, he had a wonderful collection of antique and pedigree cars and no candle production worries. Alas, he died in 2019, but before that I had toured his collection. "Wow" best suits it.

@edsnova posted:So glad you got underway on that carb linkage. I saw that extender bit and was about to ask about it.

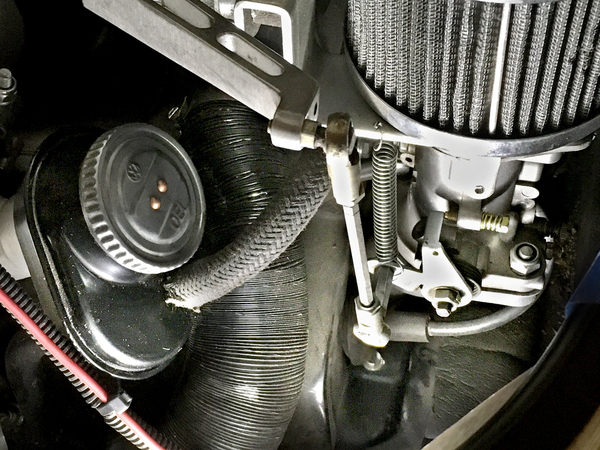

It seems to be a type4/DTM shroud issue. Lenny's linkage(DTM/type4) had the extensions both on the carb base and on the throttle levers. The spacers move the bar backward, to avoid interference with the shroud.

I don't like the way it looks but it seems to work.

CB Performance supplies one spacer to fix the offset on type1 linkages as well.

I know it would be near impossible to install and adjust, but is it possible to install the linkage reversed? That's how mine is on my Spyder, but I'm lucky enough to have a 911 shroud that actually isn't in the way.

I believe the synclink doesn't work with a stock shroud with the heater air outlets. If so, this is disappointing.

.

@Michael McKelvey posted:I believe the synclink doesn't work with a stock shroud with the heater air outlets. If so, this is disappointing.

I've heard this, but I think you might make it work. I've got the stock shroud with heater tubes, and it looks like this on the passenger side (a little tighter than driver's side):

The tubes are flexible and can be 'munched' a little without hurting heat flow much. I guess it also depends on which oil filler tube you have. The old stock VW filler (shown here) does get in the way some, but you could use something more compact, I guess.

I also have a small tube from the breather box connected to the oil filler, which doesn't help either. But it's important to remember that the cable to the synchlink doesn't need to feed straight in and can be deflected a little, too.

.

Attachments

I spent a couple of hours at a local shop that does muffler work this morning. They were good enough to take on my custom job, not all shops want this type of work. The tech had a real challenge but in the end I am happy with the results. He was able to use an A-1 (In & out the same side) high flow muffler that I had. It is actually perfect for the space I have left with the BAS header being so close to the rear valence. I needed the muffler to be installed so it can be easily removed to access the valve cover. The tech was able to accomplish this and have the tailpipe exit through the original cutout in the body. I plan to remove the muffler and grind the welds some and clean off the rattle can silver paint to expose the natural stainless finish. Not a bad job for what we had to work with. The muffler sounds great, it is actually quiet until the carbs open up then it has a deep rich roar. I am just glad to be able to drive the car and to start getting the carbs jetted. I drove it 15 miles up to my business which is all secondary highway . The car is very close to being tuned in. I need to play with the timing to see what amount of advance the engine likes best. Upon arrival the engine was only warm to the touch on the top side and the oil temp only warmed up to 66 degrees Celcius (about 151 F) which is ok in my book. It is a cloudy 55 here today. So the DTM is doing its job (Maybe too good). Having the engine sealed well keeping only fresh cool air going into the fan and carbs makes all the difference. More to come as I drive it.

Attachments

Very nice!

I concur.

Very nice, Jimmy. Now you need a louvered grill to cover up that gap where the original VW exhaust exited.

Coming together nicely. The muffler install looks great.

Sweet, Jimmy! How does it match up with the Subie spec transaxle?

Thanks for asking Michael, The trans gearing appears to be a very good match. The engine actually feels very similar to the Suby engine in my Speedster but I think it is going to have more power once I explore 1/2 throttle to full open driving, I haven't pushed the engine yet. The funny thing is that I am running the exact same A-1 muffler on both cars as well. I had little doubt the trans would be a good match. I really like the gear ratio choices they build this trans with. All the gears are a tad taller and 4th gear gives me 70 MPH at 3200 rpm. So yes to me it feels like a good match.

@dlearl476 posted:Very nice, Jimmy. Now you need a louvered grill to cover up that gap where the original VW exhaust exited.

Some people are never happy LOL ...All kidding aside, Yes that would be nice. This will be on the to do list when the car gets in the hands of a body shop. I will have them fill in the cut outs for the dual exit exhaust and fill and smooth some stress cracks. For now I am going to drive the car while I can to get the engine tuned just right. My next thing to do is replace the stock pushrod tubes with special longer pushrod tubes I just bought from European Motors . A couple of the stock ones are leaking because of being too short, they are right at the edge. The engine is almost an inch wider than stock. I had to search a bit but found that longer tubes are made just for monster type 4 engines. The longer tubes have an extra O ring groove. I just hope I can get the tubes switched out without taking the header back off. If I do I will probably just pull the engine and switch to a V2 DTM now.

Attachments

You should be able to, Jimmy. The type4 tubes pull straight out through the heads. As long as you have good access to the rockers/pushrods, you're good. I hope.

@Jimmy V. posted:Some people are never happy LOL ...

Like they say in the Ducati Monster forum: "there's no such thing as being 'finished' with your mods." ![]()

i could swear I saw a model of 911 that had a panel with vertical slots (like the oil cooler panel on the front of a Spyder) between the over riders below the license plate panel, but I can't find a picture of it. 911R maybe?

Attachments

The longer pushrod tubes are now installed. They are about a 1/2" longer than stock and have a provision for an extra O ring on the side that goes into the engine block. That cured the little oil leakage I had on a couple of the factory type 4 tubes. I also had a leak on the passenger side outer axle seal that I had recently redone during the new Rancho transaxle install. I found that the inside spring on the rubber seal had come out of place. I had an extra seal kit and the leak is fixed. I have now driven the engine approx. 125 miles. It is really powerful even though I still am taking it very easy during the initial break in miles. The couple of times I have opened the throttle past 1/2 way resulted in an incredible amount of forward thrust and an extremely aggressive exhaust note. It moves through the gears scarily fast and a couple of times I have found myself north of 80 before I realize it. I am very happy with how cool the engine runs. A DTM fan that is setup correctly is an efficient system. I am looking forward to getting the Sync Link throttle cable system in and installed. The carbs are not perfectly in sync and getting them synced up should unleash more of the power this beast has. I have really enjoyed driving this. I took a couple of pics tonight around 6:30 pm which was the magic hour for perfect lighting to take pics.

Attachments

Gorgeous car, Jimmy! 👍👍

There is another Puma for sale on Samba that looks to be a great deal. If I had space I would buy it, these little cars are a blast to drive. A Suby WRX engine would be fun in this Red Puma. Anyone want a good Puma?

@Jimmy V. posted:Anyone want a good Puma?

This car seems like quite a deal. If only I had extra garage space...

Gosh, yeah. That seems like a nice one.

@Jimmy V. I like your bumpers better than those on the red Puma.

@Michael McKelvey posted:@Jimmy V. I like your bumpers better than those on the red Puma.

^ That. 100x that.

The later Pumas, like impact bumper 911s and post '73 Camaros and 'vettes, lost something very beautiful (slim chrome bumpers).

"The later Pumas, like impact bumper 911s and post '73 Camaros and 'vettes, lost something very beautiful (slim chrome bumpers)."

Actually I think the "impact bumpers" are fakes added to make the car look more current. Unless they were connected to the frame, they won't help. I absolutely prefer the originals like on Jimmy's car.

I think I'd take a Puma either way. The later bumpers aren't nearly as bad as most everything from '74 on that were modified to accept the 5 mph bumpers.

Hey Jimmy, I found your next project!

I mean...you add this and a 200 NOS to a little Type 4 and you're starting to get some real power...

I received the sync link throttle linkage kit arrived Monday. The parts are all professional looking and in marked bags with detailed install instructions. I have the kit about half installed, which is the arms that bolt to the carb bases and the aluminum pulleys that screw on to the throttle shafts. I turned the carb bases around to make more room and for a cleaner look. I will have the install completed tonight I hope. The end result will be smooth perfectly synchronized throttle operation. I really like the looks of this setup and will let you all know how it does.

Attachments

Looking good, Jimmy. Did you order a V2 DTM?

Yes I have one, I am going to wait until after the first of the year and pull the engine and install the V2.

There is a lot to report other than the election!

I finished the install of the synclink throttle cable system and I love it. The cross bar linkage I had didn't keep the carbs in sync. The sync link is a well made and designed system. The throttle pedal feels smooth and light and the car really drives nicer now.

I took the Puma on a ride down some twisting country roads today and it was a blast to drive, ripping down the straights and around the curves. This is a fun car!

Oh, and by the way I just bought the red 87 Puma GTI that is listed on Samba. The owner and I came to an agreeable price and the deal is done. I am now working on logistics to pick the car up. I guess I will now have his and her Puma's, it helps that my wife loves Puma's.

Attachments

Now you just need a white Puma and you can be your own 4th of July parade!

Correct me if I am wrong but does the Red Puma have a generator instead of an alternator?

It definitely looks different than my alternator.

You're a wild and crazy guy, Jimmy V.

Well the crazy part for sure!

Soob in the new one then?

My plan is to put a Suby in one of them and have heat and air to make a semi daily driver. We shall see.

Bad news and a bad day yesterday. I took the Puma for a short drive and was planning on pulling the engine when I returned to get it ready to switch to the V2 DTM low profile fan shroud. I was accelerating away from a stop light and the new sync link throttle linkage stuck open. I have had this experience before with other cars and it is a little disconcerting but I know what to do. Soon as I felt the throttle stick open (the car was pulling hard in 2nd gear and heading to rear end the car in front of me) I hit the brake and clutch as I was reaching for the ignition key. It seemed like time went into slow motion except for the sound of my monster type 4 free revving up higher than I thought possible. It felt like it took an hour for my hand to leave the steering wheel and turn off the key. I heard a bang from the engine at almost the same moment I got the key turned to the off position. I coasted to a gas station and found the reason of the stuck cable and freed it up. I tried starting the car and it turned over but wouldn't start and a banging sound can be heard one time each revolution of the engine. A friendly Christian guy traveling from Cincinnati back to St. Louis gave me a tow home with a tow strap, he even helped me push the car up my driveway and onto the lift, what a nice thing to do. I pulled the engine today and stripped it to a long block. The engine can be turned by hand but once each revolution you can feel something hanging up a bit. Non of the valves are going up and down. I went to remove the pressure plate and found that the fly wheel is flopping around and all of the bolts that hold the flywheel to the crank are loose. So I am not sure what all is messed up but it doesn't appear to be good at all. The engine is being dropped off at the builder tonight at 7:30. I will post what he finds when he tears into the engine later this week. I wish I would have invested in a rev limiting rotor button.

Attachments

sumbitch!

Sorry to hear this, Jimmy.

Ugh! Hope it is recoverable when you get it opened up.

Shoot. That's Awful. My E procedure is to just hit the brakes and reach for the key. Push in the clutch and there's nothing stopping it from bouncing the tach off the pin.

(But I understand being behind another car)

i hope its its not too messed up.

Oh man, what a bummer. I hope it can be rebuilt without too much trouble. Might I offer a suggestion? Add an ignition system with a rev limiter, such as Pertronix III or MSD. It'll save your engine from grenading if you ever get into a similar situation. Loose flywheel bolts are an odd symptom though, hmm...

So sorry to hear this, Jimmy. I hope that the work to get the engine back in shape isn't too much of a problem for you. Good luck with it!

Really sorry to hear this. Glad you're alright.

Jimmy. Sorry to hear this. Similar situation with throttle stcik in a van with trailer on interstate. Just killed ignition. Used engine brake to help.

Also when racing SV 650's the crank would actually break if revved too much. Break would happen between case bearing and generator magnet... hope the motor isn't too hurt.

Ouch. You'll get it sorted though, I have faith.

.

Hoping for the best, Jimmy.

For better or worse, this is what these cars are all about. They offer the possibility of something unobtainable in mass production but with the uncertainty of one-off hand fabrication.

We've all been there to some degree - the weekend upgrade that turns into weeks of down time because of some detail we could never anticipate.

Keep the faith. The rebuild almost always comes together better than the first attempt. All it takes is patience.

And, well, occasionally some money is involved, too.

.

The engine is in the hands of the builder. He is going to tear into it and tell me what is what. I am really curious to hear what is broken.

I am thinking of going with a different cam since the case is going to be split. The 86a cam is a little mild for the heads I have (435/290). I am thinking of going with a split lift and duration Web cam 86B/86C Intake .500" lift 300 duration/ exhaust .507 lift 310 duration. Yes I am crazy.

"Yes I am crazy."

You're in good company, Jimmy.

Yeah, you're crazy, but crazy in a good way.

Keep the faith, Jimmy!

DANG! Glad you are OK with no other calamity that could have very easily happened in that scenario! WHEW. ![]()

Your great attitude in the face of diversity is a blessing and a gift. I bet you could overcome anything!

Good on ya, Jimmy! If any of us have a problem that can be fixed with money, it's not that big of a problem.

Glad there was no accident. bummer on the motor Jimmy. Interested to here what the mechanic says.

@sethsaccocio posted:Glad there was no accident. bummer on the motor Jimmy. Interested to here what the mechanic says.

I was cringing as I read the story, thinking that the nearly irreplaceable Puma front end would be the punchline

... but then, just the engine! You did everything right, shutting it down, etc. We'll see how bad the damage is, but mechanical stuff won't keep you down long.

Bodywork would have been no bueno.

Thank you all for the encouraging words. I haven't driven my Speedster in a few weeks because of being emerged in the Type 4 Puma project. I drove it to work this morning and was delighted by how nice the Suby Speedster drives and was wondering how I got pulled back into the torturous world of air cooled hell! I can't explain it, I thought at one time I was through with this but I got pulled back in. There is some inherent attraction of the air cooled engine. I have memories of a special type 4 engine I bought from a builder in New Jersey back in the late 90's and this engine was amazing and bullet proof. I ran this thing hard and the worst that ever happened from over revving trying to gain another 10th of a second auto crossing the car was having a rocker arm come loose from the push rod.

I am tempted to go straight to a Suby conversion and sell the Monster type 4 off once it is fixed, and there will be money involved in the fix. I should know how bad as early as tomorrow. My guy is covered up but I know he will be tempted to tear the engine down to find out what is broken. He said he was surprised something broke. The engine was built to take a lot of rpm's.

Attachments

My reflexes and instincts didn't consider that the car is heavily insured by Hagerty, I just reacted to save life and limb. LOL..and car..

I'd like to hear how the SyncLink failed here.

@edsnova posted:I'd like to hear how the SyncLink failed here.

Me too.

"Noise once per rev, valve inop"

My money is on broken push rod/rocker thingie. Hopefully there isn't any ancillary damage.

The synclink cable just hung up from the friction of the cable in the sleeve. The instructions said that most weber carbs shaft springs are strong enough but some may need an extra return spring on the bell crank arm. I drove for 2 days without issue. Then I had an issue.

The damage is inside the case. All the rocker arms are intact and riding on the pushrods and valves. It is going to interesting to find out what broke. As I said earlier, if he has to split the case I am going with a little more cam. The webcam 86b/86C split lift and duration. I think it will allow the ported heads to produce all the HP they can.

You'll get it all good and back to screaming around in no time.

I would recommend some kind of limiter on it this time, whether it's a rotor, an MSD box or whatever.

This is NOT an "I told you so" because I didn't and I've never even thought about the possibility of a stuck throttle blowing a motor up.

But it's a lesson we all are learning right now, at Jimmy's expense. We get the lesson for free, so take heed, people.

This makes me glad my Mallory electronic ignition has a rev limiter. I have hit it once.

I have a 6500 rpm rev limit dist. rotor sitting on my work bench. I bought a new flame thrower 009 distributor and never got around to switching it to the rev limit rotor. Lesson learned the hard way. I have never owned an expensive engine that didn't have some type of rev limiter. This was the first and last time..It will never happen again! I have a feeling it will be at least a $1000.00 mistake. I am hoping for less though.

Gonna set the Spider's Black Box at hard limit 6200 rpm, probably.

The loose flywheel is odd, but I’m guessing a broken cam gear. I had this happen in one of my drag cars years ago. For the record it was a Magnum straight cut gear and let go at about 7500 rpm. Never really determined why, but replaced cam, lifters and gear and ran that motor for another season.

Ed, you have a Raby type1, 6500 is fine. That's what mine is set at. Timing goes to 0 degrees at 6400, and a hard cut at 6500.

The loose flywheel is odd, there are 5 bolts on a type4, correct? Any Loctite used on the bolts, Jimmy?

My engine builder is called this morning to let me know that the camshaft is broken and the cam gear is a little beat up but everything else is not harmed. He is going to split the case and replace the cam and lifters and check everything out. He ordered a new set of factory flywheel to crank bolts to replace the ones that came loose. I am going with the hotter cam to better match the 48/38 stage 2 ported heads. I am going with the Webcam 86b/86c dual duration cam which has the following specs.

Web Cam Type 4 Camshaft, 86B/86C Grind, 00-662 is designed for Type 4 engines, and it's specs are (In/Ex) .500/.507" Valve Lift with stock 1.3:1 Rockers, 300/310 degrees of advertised duration, and 260/272 degrees of duration at .050". This is an outstanding Type 4 camshaft, longer exhaust duration to aid with the pitiful Type 4 exhaust port! This has a fantastic midrange and top end, and is one of Web Cams best Type 4 grinds for big engines, with a powerband from 3500 to 7000 RPMs, the more headwork and carburetion the better the top end will be.

I think this cam will be perfect and I can't wait to see how it runs. The builder is going to sort out the suspected head to cylinder leakage. The engine was a brute with the smaller cam and heads leaking, I really can't imagine what it will run like now.

I have decided to hold off on buying the Red Puma. Too many things going on now to add that into the mix.

Attachments

Very good info, Jimmy. It sounds like a decent plan. I wonder if your engine guy will find an occlusion in the cam, which would explain the breakage.

Does the type 4 use a copper head gasket? Or does the head just interface directly with the cylinders? I always put some valve-grinding compound on the cylinders and hand-lap into the heads. No leaks yet.

He told me that it shouldn't have broke from the high RPMA and he is going to talk with Webcam to see what they say but he don't get your hopes up. Once the cam is out and we can look at the broken ends we will see if it shows any signs of defective material. I don't like the way this happened but I do like the chance to get this hotter cam into the engine. I have confidence it will be a good match to the heads and make the engine develop more power.

Bill is going to check the heads to make sure the surface the cylinders seat on have been cut to the same depth, if they are not the same he plans to fly cut them until they are square and parallel and the same depth. He will use a copper ring gasket the thickness of the amount removed from the heads to keep the compression ration the same.

,,

.

You know, Jimmy, it's really OK - you're among friends here.

There's no reason at all to be inventing this story about a run away throttle and a broken camshaft.

We all know what happened and can relate.

You're building the biggest, baddest mill ever and then, at the end, are having doubts about whether you're going too far. The hot cam sounds like the icing on the cake, but is it too much? Will you forever be stuck with a lumpy idle and a cold-nosed shrew that's impossible to start? You played it safe with the milder cam, figuring that was the adult thing to do.

But then the day of reckoning. The first time you backed it out of the barn and put your boot into it, you knew.

Coulda, woulda, shoulda.

It needed the hotter cam like chips need salsa.

I will grant you that this story you've made up does check most of the boxes. It neatly explains how nothing else in the innards got tweaked or busted and that the only thing needed for wholesome perfection now is - well, I'll be - a new cam!

What tipped me off was laying all the blame on the SyncLink - a work of godly perfection that might just as well have been handed to us by Moses on the mount. I think a more plausible fall guy would have been practically anything else in the linkage - you must have some crudely finished EMPI bits in there somewhere.

At any rate, the worst is behind you now. No one's seriously questioning your story, and we're all on your side.

Isn't it funny how we never lie awake at two in the morning sweating over the throttle response on the Camry? Could it be just a little crisper? Should I look into cleaning the throttle bodies?

Never happens.

But, ah, Jimmy, these funny little cars weigh on our minds, don't they?

.

Broken cam, huh? Interesting. I guess he doesn't know where until he gets it apart?

When I was visualizing my broken push rod theory I considereded that the cam/gear flange had twisted off due to resistance in the valve train not being able to cope with the R's.

Fingers crossed they're going to rule it a defect in workmanship and, at least, give you a free cam.

@Sacto Mitch posted:.Isn't it funny how we never lie awake at two in the morning sweating over the throttle response on the Camry? Could it be just a little crisper? Should I look into cleaning the throttle bodies?

Never happens.

But, ah, Jimmy, these funny little cars weigh on our minds, don't they?

Everybody looks at things a little differently, and especially cars. Because nobody (or at least nobody I run with) has room or money for the 50 different cool vehicles which would each be perfect for individualized applications.

A diesel dually quad-cab 1 ton truck for hauling the trailer. A Q-Wagon for hauling the kids to soccer practice. A Maserati Quattroporte for crossing time-zones in silky speed. A Maybach Merc to show those clowns in the boardroom who's boss. A Dodge Demon Hellcat Redeye widebody Rat-Fink cartoon edition thing to show everybody down at C&C who's really the boss. A Ferrari 250 SWB to drive down the PCH. A Harley Davidson Heritage Softail with beach-bars and 14 headlamps to crisscross Nevada and Utah in style. A Sopwith Camel for severe-clear evenings, when looking at the sunset from the ground just won't do. A front-engined Indy racer for vintage track racing.

Et cetera. I'd love 'em all.

Most folks must make do with one vehicle or two, and they try to make that vehicle everything they might hope all of the others would be. This is why we have pickup trucks with Hellcat motors and leather seats in them, and FWD ricers with flares and scoops all over them. It explains an entire segment of the vehicle market, which has no reason to exist (the FWD XUV)

... but no vehicle can be everything to everybody. Jim Ignacio has cleverly written about the folly of trying.

I think that by making the choice to just buy and drive a fragile, clunky, leaky, unreliable plastic Easter egg, all of us here have made a choice (wittingly or not) for specialization, at least to one degree or another. These cars are not any good at all for a lot of things, but they are perfect for their intended task. The guys who don't last want their cars to have a wider bandwidth.

So what does that have to do with Jimmy's 2786 or Mitch's quote above? The highlighted part got me thinking about people and cars, and why stuff matters to one guy and not another.

I tend to look at "normal" vehicles as tools. My white box hardware store on wheels doesn't say anything about me-- it just hauls tools and stock and ladders from one place to the next. I don't need cool wheels or sticky rubber or a V12 engine in it, because all that would do is make a big white box that much more expensive. I don't want to go faster or look cooler or corner deeper-- I want to haul stuff around as cheaply as possible. The truck has to work for me to make any money-- so it can't be a beater, which is why I buy new. I want A/C, cruise, power locks, and no breakdowns. Anything more is just fluff (although the driver's side slider is pretty nice to work out of, and something I'd pay for again). I don't think I've washed mine since I bought it in 2014-- the rain does an adequate job.

My wife drives a minivan. She wants seats that fold into the floor, heated leather seats, a heated steering wheel, DVD players in the back for the grandkids, and no breakdowns. I want A/C, cruise, power locks, and to never have to work on it. It is not an XUV, because an XUV is just a less functional, more expensive minivan that still looks stupid. I do not have the blackout trim package, because a minivan with blackout trim is still a minivan. The Pacifica crosses time-zones hauling all manner of junk with zero drama, adequate speed, and decent accoutrements. We keep it clean, because nobody likes to sit in Cheetos crumbs in clean clothes (by way of comparison, my trucks headliner has coffee stains, because I wear work-clothes when I work, and I don't care). When the last one got caught in a hail-storm, we named it Hail Mary, pocketed the $10K State Farm gave me and drove it another 50K mi before selling to my daughter.

Things are meant to be what they are-- no vehicle can be everything. "Cool" is probably the hardest thing to pull off, and offers the least return on investment. However-- I've always said that if a thing is cool to me (and nobody else), then it'll always be cool to me-- because my opinion of it isn't dependent on somebody else's whims.

So no, I don't obsess about the throttle response in either of the more utilitarian vehicle/tools. If they work for the intended purpose, then they are fine.

However... I understand that with my plastic-fantastic, everything is something to obsess about. I've dreamed (like, while I slept) about flame fronts moving across the top of pistons, and of oil squirters spraying the underside of piston domes. Obsession doesn't quite cover it. It's madness.

These are hobby-cars, meant to be fussed over and pampered. We have a 4-page long thread every 2 months regarding motor-oil for crying out loud-- and I care about it! I've redone my transaxle more times than I can count, only to end up pretty much where a stock VW has the gear spacing (albeit with a 3.44:1 R/P). We don't just obsess about throttle response-- we build $10K, near 3L 4-cylinder engines we know are going to need torn down for this or that. A man tells us his tale, and we all offer encouragement, because we know we'd do the same thing.

This is not how most people think. They do not understand building a new house so that one can have a lift in the garage so that the car that always needs work has a place to have it done. They are content to tint the windows in their Ford Escapes, and to get the Titanium edition of same.

Jimmy is not that guy, and neither are any of the rest of us. That's why I stop in here several times a day, for 20 years now. It's pretty nice to not have to explain myself.

Sacto Mitch, Stan Galat and the rest of you with the same sickness as me, thank you for your support and comic relief, for without both this thing we do would not be nearly as fun. I love what both of you posted and couldn't stop laughing as I read your post Sacto Mitch. I am not sure what you call that type of humor (satire) but it sure made me smile. Thank you both for helping me keep some semblance of sanity as I deal with the event I am now calling the "unplanned high RPM testing of my new engine".

Jimmy.... Let me know when you are to have your planned "High RPM" test.....

My blood pressure could use a boost...... Just ask Stan....

More news from the engine builder. He has the engine torn down and the good news is nothing is damaged at all except the cam has broken right behind the flange that bolts to the cam gear. We both say it is a bad casting and would have broken sooner that later. The loose flywheel bolts are another thing. I have to look through my receipts but I supplied the new bolts and flywheel to the builder because the engine didn't come with them. I bought the bolts from the type 4 store or LN engineering either way the bolts are soft and not good. Bill said the had stretched. He has ordered German stock bolts. He also found that all 4 heads were leaking at the bottoms. He is going to investigate why the had leaked but told me regardless of the reason he wants to use copper rings that are machined to fit into a channel cut into the heads. He does this for turbo 911 engines that develop huge cylinder pressures. He has guaranteed they won't leak when he is finished. Just think, the engine ran strong with leaking heads, I am excited to think how strong it will be now with the leaks fixed and the stronger cam. Bill has all the parts ordered and will be working on the engine later next week.