Hey Guys,

I’m at the pointy end of my engine upgrade project and thought I’d share some details and seek a little advice from the brains-trust.

My end-goal is to have a reliable engine for daily/touring use, with a little more grunt to get me out of (or into 😊) trouble if needed. I did quite a lot of research on this site before starting the project and gleaned a lot of really helpful information.

I should also mention that this is my first ever foray into the world of “engine builds” so on the advice of a mechanic friend, I short-cut the process somewhat and utilised the skills of his trusted engine builder to supply a rebuilt 2.0L Type 4 long block, with the plan to undertake an upright conversion myself using a CSP conversion kit.

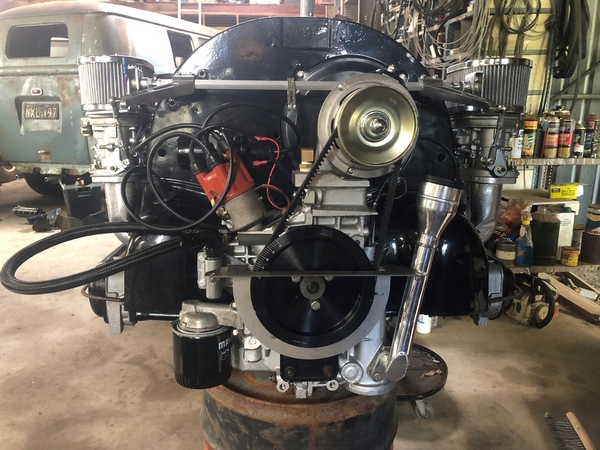

Over a number of months, the rest of the build-out by my mechanic friend and I slowly progressed to the point where we started up the engine a few weeks ago on the bench. Fired up first try and it idled really well.

Basic specs are as follows:

- 2.0L Type 4 engine with mild performance cam (unfortunately don’t have more details)

- ‘CSP’ upright conversion kit

- Dual ‘Weber’ 40 IDF carburettors

- Remote oil cooler

- Electronic distributor

- Electric fuel pump

- 200mm conversion flywheel

- ‘Vintage Speed’ sport muffler

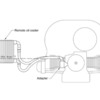

We’re installing everything this week but I do have a couple of questions regarding the external/remote oil cooler set-up. Like many on this forum who have installed an remote/external oil cooler, it will be located in the driver’s side rear wheel well and, from eye-balling things, likely quite a bit higher than the engine sump. I’ve read @Gordon Nichols 4-Part tech article on external oil cooler installation several times which has been extremely helpful (thanks mate!) which also identifies the need for extra oil to be added to the system but I have a few questions:

- Is a non-return valve required to stop the oil in the oil cooler draining back into (and potentially “flooding”) the engine case once the engine stops and/or cause a problem on start-up?.

- Is it better to plumb the oil cooler for the pumped line “in” at the bottom and the return line “out” from the top, or vice-versa

Am I being concerned about nothing? Is the volume of oil contained in the oil cooler I’m using (EMPI 96 plate cooler) small enough that it won’t cause issues??

I've attached a drawing of the level I believe the remote oil cooler will be in relation to the engine/sump and the level (dashed line) I believe the oil may drain to when the engine stops.

Many thanks in advance for any advice you guys can provide.

Kindest regards, Tony

). Message received regarding sealing the engine compartment, will do

). Message received regarding sealing the engine compartment, will do  ....and yes, it's going into a 1978 California built IM.

....and yes, it's going into a 1978 California built IM.