Radiators for our replicas are like many automotive subjects that sound simple, but can be very detailed on many levels. Anyone really interested needs to do lots of research online, as materials and technology have advanced in the last few years.

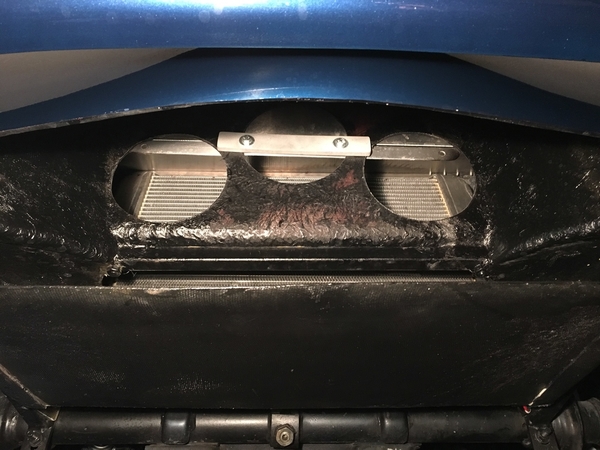

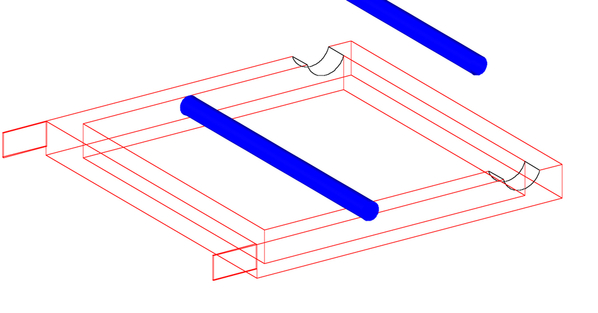

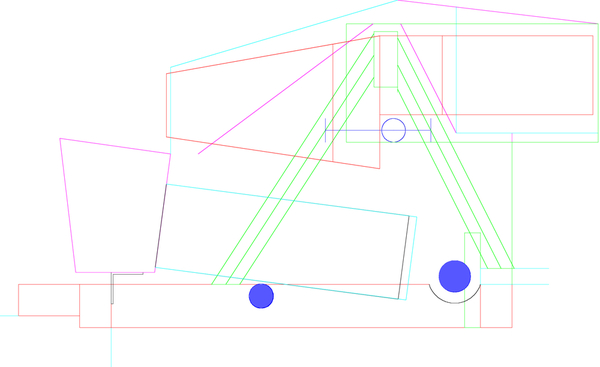

Some generalities apply: 1) Measure the space available (length x width) and fill it completely. Many rad sites allow you to shop by size, as well as car model. Modern aluminum rads are built with a thinner profile to allow of easier air flow through the tubes, a critical facet of heat dissipation. Dual pass rads are becoming standard, and should work well with any of our applications; 2) 1.5" inlet and outlet rad tubes help with increasing flow, another critical aspect of heat dissipation; 3) electric fans are essential, along with a properly-fitted shroud that insures that all air is forced through the rad, 4) ideally, you place the rad where the pressure is high on the front side, low on the back side, 5) puller fans, mounted on the back side of the rad, generally move more air since they don't block the incoming air flow, and 6) data provided by fan companies regarding air volume moved is mostly nonsense, with Spal being an exception. Higher amperage draw of the fan motor means more air moved. Pay extra to get a weatherproof, high flow fan motor.

Be aware that Subaru engineers computed the radiator profile (l x w), based on full air flow through a non-restrictive grill at a perpendicular angle to the rad fins, the common placement for stock Subis. No way can we achieve that ideal setup in our replicas. The Vanagon guys estimate that you need 50% more square inches in a VW van/Subi swap, due solely to rad placement, i.e., air flow is restricted and not perpendicular.

The Aussies and Brits have more online research than Americans for some reason. Remote rads are also popular with some of the 4x4 guys, who have posted real world test results. Best of luck in your research.