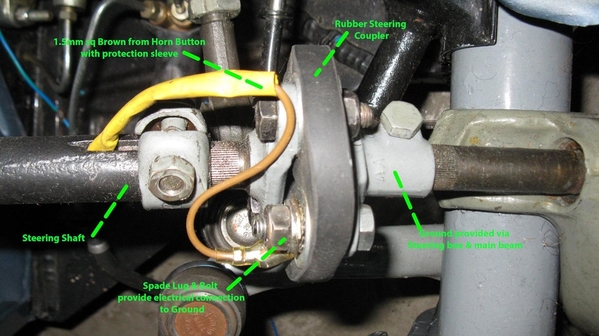

The above is the rubber coupler between the steering shaft and the steering box. Do most of your cars use a VW steering shaft/column/box? And if so, do you have the rubber coupler installed to isolate the ground for the horn button? I am trying to decide if I need to install a rubber/urethane coupler when building a steering shaft.

Also, does anybody know where to get a good deal on the seats pictured above? I have a couple un-upohlstered 914 buckets, but I am thinking that the original 356 couple seats were comfortable for longer trips, and the comfortable the car, the more my wife will like it.

Attachments

Yes. The rubber absorbs some of the road , isolates ground for the horn, it also corrects for slight difference in column to steering box shaft alignment

If I'm not mistaken, those are EMPI 62-2950 low back reclining seats, recovered in tan.

Stan good one. They make them with a headrest too that would even be safer.

IaM-Ray posted:Stan good one. They make them with a headrest too that would even be safer.

I actually mounted one with a headrest in the passenger side for Jeanie. She thinks it's more comfortable than a MB E-class seat.

DO NOT USE A URETHANE STEERING COUPLER UNDER ANY CIRCUMSTANCES!!!!!!!!!!

They will shear off and kill you. Only use OE VW rubber coupler.

That would be shear luck to have no steering.

Alan Merklin posted:Yes. The rubber absorbs some of the road , isolates ground for the horn, it also corrects for slight difference in column to steering box shaft alignment

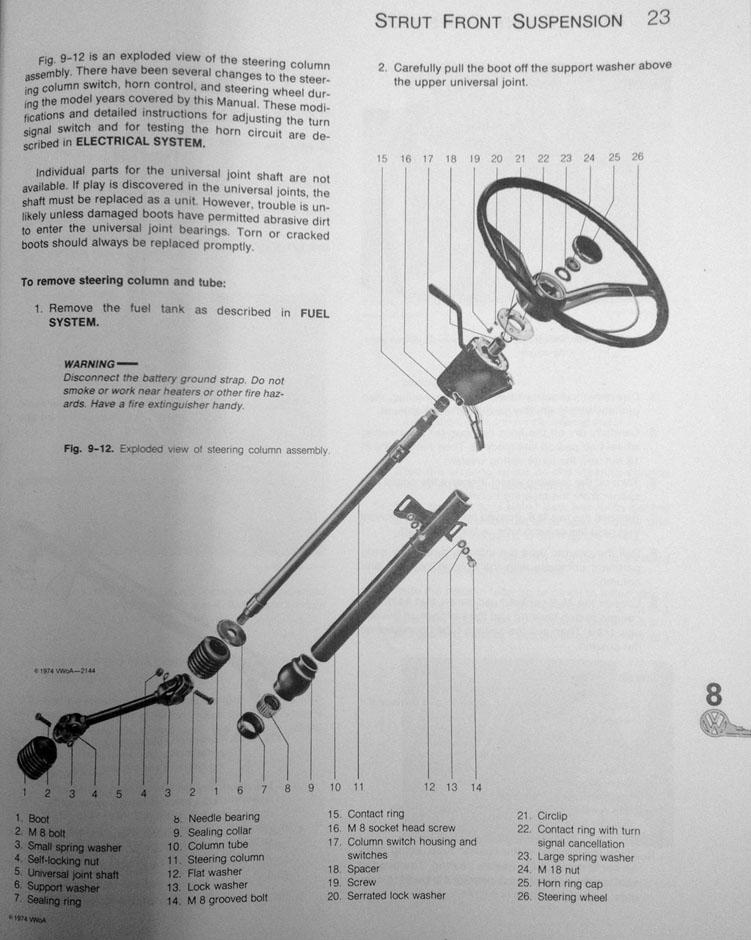

Guess you could also use the knuckle joints used on later VW Super beetle and the Porsche 914 (see #1). Late VW has a collision crush cage in the column but pre '68 uses a solid skewer you in the chest steel shaft.

Attachments

I prefer the VW T3 style as it provide the same dampening of the rubber bushings but also provides a separation point that would do the same as a crush cage in an accident.

Alan Merklin posted:Yes. The rubber absorbs some of the road , isolates ground for the horn, it also corrects for slight difference in column to steering box shaft alignment

Thanks. Ordered what I need.

You are looking for a "slave saver". It was never an OEM VW part, but every VW aftermarket supply house has 'um, even Amazon: https://www.amazon.com/BILLET-...tomotive&sr=1-16

RS-60 mark posted:You are looking for a "slave saver". It was never an OEM VW part, but every VW aftermarket supply house has 'um, even Amazon: https://www.amazon.com/BILLET-...tomotive&sr=1-16

That is perfect!

I may have the whole assembly including slave saver and slave, Todd. I’m out in San Diego (what the hell happened to the weather?!) on bid’ness but can check when I get back home.

Lane Anderson posted:I may have the whole assembly including slave saver and slave, Todd. I’m out in San Diego (what the hell happened to the weather?!) on bid’ness but can check when I get back home.

That is kind of you. And I already ordered the slave along with pedals and masters from Wilwood, and I ordered the slave saver from Amazon. But, thanks for consideration.

Just curious, what did you use it on previously?

This morning it amazed me that everyone can travel at 65 mph during heavy rainfall without more accidents. Last week, I was doing 70 when myself and the car in front me went through a puddle on the 405 in the fast lane. Couldn't see a thing for about 3 seconds, and yet everyone just went straight and didn't panic; amazing.

Hey so stupid Ed here with two (2) stupid questions: 1.) What does that "slave saver" bracket actually accomplish? In other words, what bad thing happens if you just attach one end of the slave to the old cable bracket and the other to the clutch arm, like this dumbass did?

and, B.) What does the "slave saver" bracket attach to, slave-cylinder-wise?

The purpose of the slave saver is to align shaft movement precisely, so that the shaft has little or no side play, enabling the seals and washers to outlive their ungrateful installers.

The brackets have various shapes, depending on the transmission type. They usually bolt to the case and accept a heim joint for the true believers, who understand that a leaf falling from a tree in Baltimore affects the melting of the polar ice caps.

Now, I hope that answers your question, young Master Edward.

Ed, thanks so much for asking this.

I was raised to believe that clutches should be worked by cables, that God gave us each a cable, and that cables can wander around a little as they do their work without causing any big problems.

Every once in a while, these dudes in white shirts and black ties come through our neighborhood, stopping at every house, and asking us if our clutch cylinders are saved.

I never know what to say.

I too am one of the great unwashed, struggling along with a mere cable (the horror) to engage my clutch. I know it's unduly simple for a man clearly drawn to Rube Goldberg solutions to elementary problems, but I guess I just never found the act of pushing on a pedal to be particularly taxing on my left leg.

Perhaps it is my desire to make straightforward considerations into complex conclusions at war with my higher order ape physiology. When one has a physique not unlike an orangutan, devising a more complicated way to pull a clutch doesn't really enter my sloped forehead.

I promise to do better, and will be calling OK Go to help me engineer a more complex solution.

Sacto Mitch posted:

Ed, thanks so much for asking this.

I also wanted to know why it was called a slave "saver". To me, it looked like a clutch slave cylinder attachment bracket. And I was also wondering why the parts dealers were also offering heim joints when ordering.

@edsnova Thanks for asking.

@Jim Kelly Thanks for answering.

Stan Galat posted:I too am one of the great unwashed, struggling along with a mere cable (the horror) to engage my clutch. I know it's unduly simple for a man clearly drawn to Rube Goldberg solutions to elementary problems, but I guess I just never found the act of pushing on a pedal to be particularly taxing on my left leg.

Perhaps it is my desire to make straightforward considerations into complex conclusions at war with my higher order ape physiology. When one has a physique not unlike an orangutan, devising a more complicated way to pull a clutch doesn't really enter my sloped forehead.

I promise to do better, and will be calling OK Go to help me engineer a more complex solution.

I did not think of it being more complex. I only saw that it was more expensive. And so I thought it must be better. And now that I reflect on my reasoning, I realize how dumb that rationale is. Oh well, the parts arrived this evening, so I will use what I got.

WOLFGANG posted:Guess you could also use the knuckle joints used on later VW Super beetle and the Porsche 914 (see #1). Late VW has a collision crush cage in the column but pre '68 uses a solid skewer you in the chest steel shaft.

Based on the location of the steering box, (not VW), I will have to use two u-joints/knuckle joints to position the steering column. I am posting this because I want to know if there is any safety reason one can not use two knuckle/u-joints on a steering column?

Late Super Beetles used 2 joints -

Todd wrote: " I want to know if there is any safety reason one can not use two knuckle/u-joints on a steering column?"

Short answer - No. But there's a yes involved, too.

Longer answer: Sometime around 1972 and after car manufacturers started going to transverse (crosswise) engines in the front of cars, various governments started testing them for crash-worthiness and found that, on front impact, the engine would be forced rearward and often rotate, shoving the steering column straight back into the driver's chest and killing them. This was especially true with the original Austin Mini. That's what started the "crush cage" that VW went to on the beetle around 1968.

Other manufacturers used a shorter, centered steering column and an off-set steering rack and pinion, all connected by a short shaft with two universal joints, thereby providing for movement of the engine/transaxle/frame in case of frontal crash. If you look closely at Wolfgang's photo just above, you can see how it works. this method also allows for easier placement of the rack because it no longer needed to be directly inline with the steering column.

So, yes... There is a safety issue with using two knuckles to connect the steering column to the rack. It was done to improve driver safety in case of a frontal crash.

It is currently the preferred method provided that the two shafts are off-set enough to never allow them to line up and become a spear in a crash.

My car has a rack and pinion, and this is how it is done.

Gordon Nichols posted:Todd wrote: " I want to know if there is any safety reason one can not use two knuckle/u-joints on a steering column?"

Short answer - No. But there's a yes involved, too.

Longer answer: Sometime around 1972 and after car manufacturers started going to transverse (crosswise) engines in the front of cars, various governments started testing them for crash-worthiness and found that, on front impact, the engine would be forced rearward and often rotate, shoving the steering column straight back into the driver's chest and killing them. This was especially true with the original Austin Mini. That's what started the "crush cage" that VW went to on the beetle around 1968.

Other manufacturers used a shorter, centered steering column and an off-set steering rack and pinion, all connected by a short shaft with two universal joints, thereby providing for movement of the engine/transaxle/frame in case of frontal crash. If you look closely at Wolfgang's photo just above, you can see how it works. this method also allows for easier placement of the rack because it no longer needed to be directly inline with the steering column.

So, yes... There is a safety issue with using two knuckles to connect the steering column to the rack. It was done to improve driver safety in case of a frontal crash.

It is currently the preferred method provided that the two shafts are off-set enough to never allow them to line up and become a spear in a crash.

Doggone THANKS! Your explanation couldn't have been better with photos. I understand exactly what you are saying. And now I understand WHY the previous owner/builder planned on using 2 u-joints. Unlike a VW or 356, the rack and pinion steering is located behind the centerline of the front wheels and close to the firewall. The steering box is not on center with the steering column and the arm from the steering box is angled.

WOLFGANG posted:Late Super Beetles used 2 joints -

Kool! I was wondering how I was going to cover up the u-joints, to not only keep the joints clean, but also to hide the mechanical unsightliness. According to the diagram, there are stock VW boots to do exactly that.

I personally like a cable clutch it provides more feel IMO if the leverage is appropriately done, it does not always require you to have lead added to your shoe.

Attachments

IM uses an Ididit column most times and for those who want more period correct a VW type of column. I know of one car that was built with an original 356 steering shaft and banjo wheel and even the shifter was all original. It all depends what the car dreamer wants. ![]()

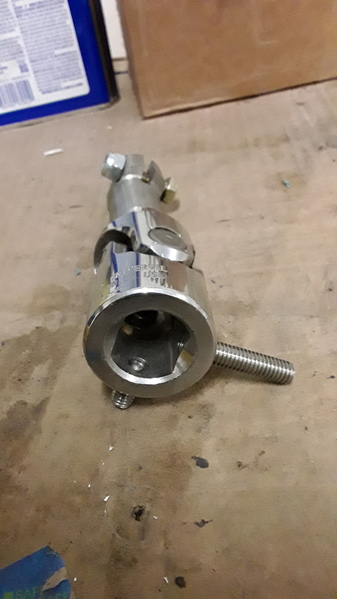

Above is the VW steering coupler I purchased to isolate the ground for the horn. It did not fit the u-joint I am using because there are 48 splines on the steering coupler and 36 splines on my u-joint. Both are 5/8" in diameter. I went looking for some way to go from 48 splines to 36 splines, but did not find anything. I can't find anything else that is 5/8" in diameter with 48 splines. In my search, I ran across a thread on "The Samba" where someone was saying that the splines are not supposed to be an exact fit, but rather the splines are there for friction. Is this true? I assumed that if you had 36 splines on the male end, you have to use 36 splines on the female end.

Attachments

I concur with the Samba Dude. While it would be nice to have them match spline count for spline count, when the clamping bolt is tightened to the proper torque (18 - 20 ft. lbs.) it clamps down on the splines, distorting them slightly and making a slip-proof connection. You may have to spread the jaws open with a screw driver to get it on, then just assemble the clamping bolt according to Hoyle, making the bolt line up with the flat on the shaft.

Oh, yeah.

Wicked big +12volt cable going front to back. Mine looks like that, too.

"Macht" I think is the German name

I don't know if would help you but I custom made & machined still have) a VW spine to 3/4 x 7/8" D shaft w/ a U joint adapter between them.

Attachments

Cable clutch all the way (until you flip the whole engine/transaxle thingie around and need a pulley for your clutch cable....).

Thanks for the response, Jim. Maybe I'll dig out the bracket and install it.

edsnova posted:Cable clutch all the way (until you flip the whole engine/transaxle thingie around and need a pulley for your clutch cable....).

Thanks for the response, Jim. Maybe I'll dig out the bracket and install it.

Not really Ed, some trannies have a pull lever or a push lever so no need to have a pulley just use the right one.