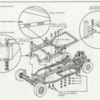

Hi there. I'm starting to gather some parts for a speedster project and I have a question about the chassis I have acquired. The outer pan support on both sides appears to have been cut or broken off at some point, leaving the rear outer edge of both pans a bit flimsy. I know VWs had a piece coming off the very end of the torsion tube that the pan support rested on and was spot welded to. I'm seeking advice on how to correct a chassis that is missing those supports. Seems like welding a small piece of tubing to the torsion tube that would then be welded to the rear pan rail support thingy would be pretty easy. Just not sure if there are better solutions or options out there. Here is a picture I found on The Samba of the piece I am talking about. This is not my chassis, and the piece here appears to be cracked as opposed to lopped off as in mine.

Let me know your thoughts.

Brad