That's great ! Sounds like the ultimate cooling set up.

If you mean the oil setup, then no - I (mostly) didn't do it for cooling the engine. More on that later.

If you mean the rest of the engine (the entire combination, as Danny keeps saying), then yes - I'm trying pretty hard. As I said, it starts with the heads and exhaust. I just completed (but have not yet installed) a 2234, which was built with heat management as one of the main considerations.

It's got a 1-5/8" A1 sidewinder and a free-flowing exhaust - how free is something the boyz who go to the Smokys can tell you. As I keep saying, this is the place to start.

It's got CB's Panchitos, but I had them set up for beehive valvesprings to reduce the pressure, but still keep the valves under control to 7000 RPM. Less spring pressure means less friction at the tip of the valve, and especially at the cam/lifter junction. Spring pressure creates a lot more heat (and wear) than people think. The beehives have been around for years (and are proven tech) but are a new thing in the VW world, a lot of really, really smart guys on the bleeding edge of things are pretty excited about them.

I'm running AA thick-wall 92 mm cylinders and forged (not hypereutectic) pistons. The idea here is that Mahle 94 mm cylinders struggle to stay round as they get hot, and it's tough to get a good ring seal. How will they work? I've got no idea, but I'm running softer Deeves rings and a Total-Seal second to try to keep the pressure inside the cylinder and the oil out. As far as keeping the oil out, I'm also using Teflon valve-seals (which nobody does). I may regret all of this, but I've really come to hate a pressurized crankcase.

I've got 911 oil squirters that spray oil on the underside of my pistons, which is old tech the OEM guys have used for years, but which really never caught on with VW aftermarket (I believe because so much of the VW world is drag-race driven). Everybody always says, "these are oil cooled engines", which is not strictly correct generally, but in this case the oil is used as a coolant (I think of it as an aid). I've done this to pretty much every engine since the very first 2110. You need a big oil pump to make it work, and I'm not sure how useful it is - but it's doing everything you can, and I'm a belt/suspenders guy. You'll hear people say "it's not worth it", (which may be true) but never, "it doesn't work", because it does.

I did thermal coatings in the combustion chamber on the 2332 and the twin-plug 2276. NASCAR guys do this all the time, but I struggled to get anybody super-excited about doing it well for me. I'm going to chalk that up in the "probably not something I'm doing again" category. I didn't on the 2234.

I run a LN Engineering DTM shroud. This cooler incorporates a T4 oil cooler on the stand, but even when I run a 36 hp shroud, I modify it for the T4 cooler. I'm using sled tins, which need to be heavily modified to work without heat exchangers and a DTM. I'm also using all of the little enclosure tins on the front and back of the cylinders. Just doing the cooling system on the stand took a couple of months of ordering parts, modifying parts, powder-coating parts, and installing parts. No flaps (as the set-up doesn't work with flaps), but Avery's Aircooled is now making a "fixed flap" set-up that seems like a good idea if I run a 36 hp shroud on another engine.

I own/operate a small HVAC/R service business, so I know a bit about airflow. I built a nice little ring to help direct airflow on the inlet of the VW fan-wheel. It's a bit like a "velocity ring" but fit much better to the fan, although not radiused, as I don't have the capability to make a piece like that. It would work better if it were shaped as such - how much better is a subject for debate, but I'm guessing it's fractions of a percent. This was the low hanging fruit and I picked it.

A dry-sump pump requires a small crankshaft pulley, which reduces how fast the fan spins. I've got a serpentine set-up with a very small alternator pulley as well, which replicates the stock ratio. That means the fan is spinning really, really fast at high RPMs (at or near 20,000 RPM). As such, I run a welded/balanced fan on everything.

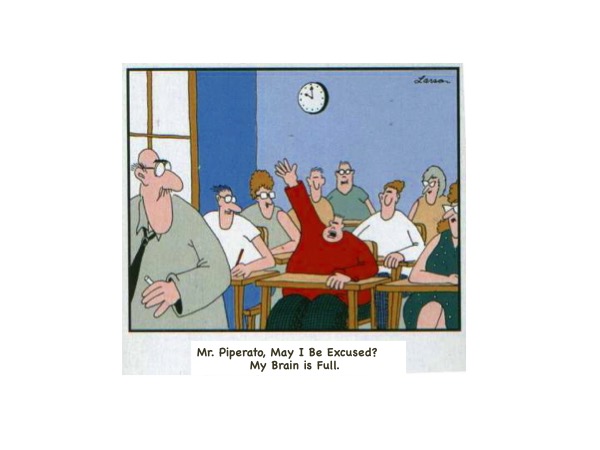

My point is that everybody asks "what can I do to improve my cooling?", when what they really mean is "what can I do that will make me feel better, but not cost a lot?". The answer is "get a better exhaust than you think you need, and get heads that flow and cool well". There's a lot you can do after that, but that's 90% of it.