Has anyone installed and used a PerTronix distributor with favorable results? Looking to replace down the road the original 009 in my 1600 with a mild cam. Just looking for good med-range output on hilly country roads. Thank you for input, Michael

Replies sorted oldest to newest

It's a copy of the MSD and i question it's quality.

A "mild 1600", i'd go with a Bosch 019, a much better curve than the 009 and it was the "original Bosch Screamer" sold in the 60s and early 70s. The Pertronix 1844 does drop in if you dislike points. The 019 also has that vintage look, like the original Speedster distributor.

I've been quite happy with mine for several years now. No issues.

Hello Glenn, I noticed Kirk at VS had taken out the points to my 009 during installing 40mm dual carbs, but not sure yet what he did- trying to look and cross reference what I see to what electronic gizmo is in place.

To clarify, I have the Pertronix "Billet Flamethrower II" ignition. They are now producing the Flamethrower III version: http://www.pertronix.com/prod/new/details.aspx?ID=110

Michael B (aka bluespeedster SoCal) posted:Hello Glenn, I noticed Kirk at VS had taken out the points to my 009 during installing 40mm dual carbs, but not sure yet what he did- trying to look and cross reference what I see to what electronic gizmo is in place.

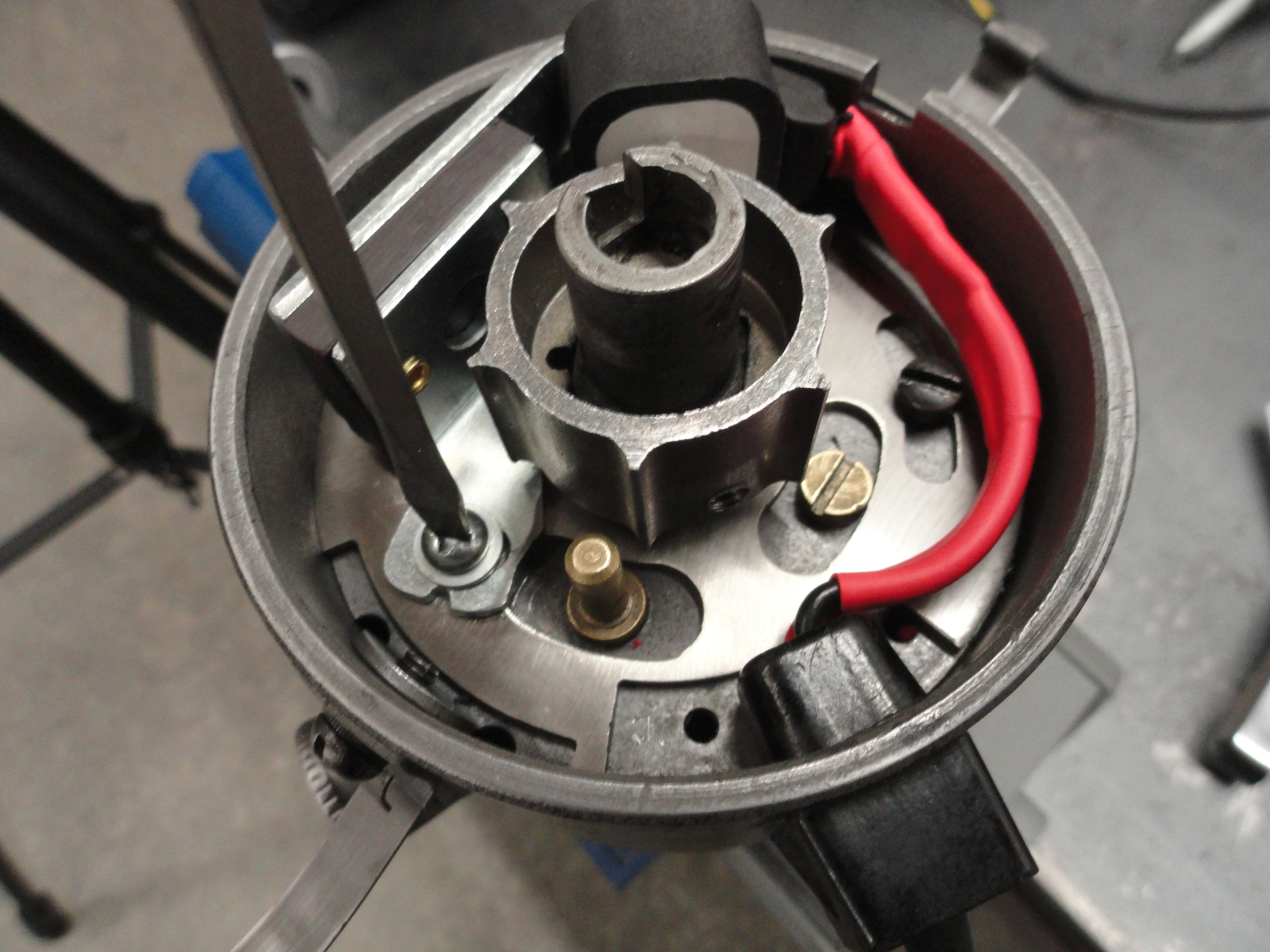

This is what a Pertronix points replacement looks like. It has a red and black wire.

Michael, I can only tell you my experiences, so classify this not as 'advice', but as just another data point.

My original engine was equipped by VS with a Bosch replica distributor with an electronic module inside that was also a replica of the Pertronix module. I struggled trying to get that engine to work for a year, going through everything from carbs to exhaust. We finally sorta got it running, but it always had what sounded like an intermittent miss.

When we finally sent the engine back to Kirk, he said the problem was a 'bad distributor'.

We put a Pertronix distributor in my new engine, a mild 2024 cc stroker with Weber 40 IDF's, and when the carbs are tuned, it runs like a sewing machine - only with more power and torque than a sewing machine.

We used the most basic 'Bosch-look' Pertronix, the D1866, which is here on their website.

There may be better stuff out there (I know you can sure spend a lot more money than I did), but this engine runs well from idle up to 5000 rpm, with no flat spots.

Sacto Mitch posted:

That's a Chinese 009 clone with a Pertronix module inside. Pertronix does not made the distributor.

Also i've tested a few Pertronix modules and found the magnets are not exactly 90* apart. So it's possible that some cylinders are running 3-4* advanced and hotter. Putting magnets in a small diameter plastic ring is not precise. OE distributors use a metal reluctor which is more accurate.

Thanks for the info, Glenn.

I wonder if Pertronix does any QC screening on the Chinese units before using them. In any case, I've so far had no problems with mine.

A friend involved in manufacturing for that company that makes most of our computer chips spent many years working with Chinese fabricators and suppliers.

He said the Chinese can make practically anything to any desired standard IF they are held by contract to a specification. It's up to the engineer writing the spec not to miss anything or the Chinese will find the cheapest possible way to meet the spec.

If you forget to tell them that the alloy in your widget has to withstand 2000 degrees without distorting more than .01 mm, it won't.

So, he said, most of the problems with absolute junk made on the other side of the Pacific begin with lazy, clueless, or budget-strapped engineers on this side of it.

Agreed.... your iPhone is made in China.

The 82mm crankshaft in my engine is made in China. it's made to a higher spec and then "blueprinted" in the USA.

I can tell you for a fact that most Chinese 009 clones wholesale for $12 and that includes the tuneup parts. That's how they can sell for $50 retail.

Sounds like the "normal" 400% uplift for retail, huh?

My muse, Mitch, wrote; "So, he said, most of the problems with absolute junk made on the other side of the Pacific begin with lazy, clueless, or budget-strapped engineers on this side of it."

That's only partially accurate. The designer or engineer (those are different people, usually) come up with a design and specify the parts and tolerances they want to see in the finished product to produce the optimum result in their product. They are proud of that.

Usually, the LAST thing you want is for one of the designers to be in direct contact with manufacturing or the supplier. Why? Because the designer/engineer will constantly pester them for perfection (even when the rest of the design doesn't need or want it) and that drives the costs up.

So....What to do? Well, most companies turn the corporate/supplier liaison function over to a non-engineer in purchasing. Someone who is usually NOT an engineer, but can read a spec and really has the company's bottom line at heart, so they negotiate for the lowest cost good to sort-of, kind-of meet that spec (on a Wednesday, under a Blue Moon, in the rain.....That sort of thing). The result is actually a broadening of the spec (the"Blue Moon" Law) which results in some percentage of sub-standard parts (per the designer/engineer's wishes) and some over-standard parts (per the buyer's wishes) so everybody is kinda-sorta happy, except for the customer who might occasionally experience some sub-standard performance.

That, my muse, is how the industry works.

And yes, your iPhone is assembled in China, by Foxcon, a company based in Taiwan, who can build anything you want (they employ well over a million workers, world-wide) to any quality level you are willing to pay for, negotiable through your contract. They are usually not interested in an assembly contract for less than a 500,000 units per year.................

I used to use Celestica and Solectron to build my PC boards - they're cool companies, too. My disk drives usually came from Seagate in Pinang, Malaysia, near Singapore. Loved to stay at Raffles - felt like I tripped back into the late 1800's. And there was a noodle market across the street on Saturdays!

So, Glen is sounds like one important factor is getting a unit with properly manufactured and spaced magnets or the expensive unit is junk. Your engine experience with VS was exactly the same issue I had with my 1600CC; ran great for a week then pooped out. They found the carbs bad and then the distributor system which the carbs when from a 38 to 40 size with some distributor electronic switch out which I can only see a black disc with four metal buttons 45° apart. Surely no looking what your PICs show.

So, I had taken the distributor top portion apart to find a Compufire electronic ignition kit installed. Seems to work well with the blue Bosch coil, but have no idea in comparison to the PerTtronix product line?