Here are some things to consider that have not been mentioned (unless I overlooked them).

Registration can be different. in some cases it can be harder and in other cases it is actually easier as some states are starting to ban "dune buggy" type builds where a pan is rebodied. Assuming your handle is related to the state you are in, CA seems to be easy for a pan, but it can be done for a tube chassis as long as you follow the proper steps.

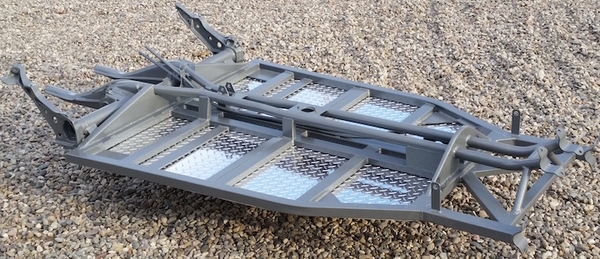

Quality and strength of the "tube chassis". I've seen some that looked like they were welded with a Harbor Freight 110v flux core DIY welder and I've seen some that were beautiful. Likewise, look at the engineering. I've seen some of these tube chassis that were an absolute JOKE with nothing more than a few 1/8th wall tabs holding a torsion housing to the "chassis". Center tunnel: Yes, a low profile center tunnel is a neat touch, but the center tunnel of a VW is also the MAIN structure of the chassis. This is why our low center tunnel sits on two 0.120" wall 1x2 on edge that run the full length of the chassis and continue under the frame horns!

Geometry. Now this one can be a hard one because some of this the average person cannot "see" and it needs to be measured or tested, AND I'd say it mostly applies to the front suspension, but it COULD apply to the rear. Before designing our own a-arm front suspension we tested several others. Some just weren't a good fit for my chassis, but several had geometry that was a joke. Literally had a few that we looked at with reverse Ackerman and bump steer off the charts!

In short, do your homework.

FYI this is not a plug for my own chassis, we don't sell a chassis alone and likely never will, I am just using mine as an example because we addressed all of these concerns while engineering it...