Go Kelly. You got this.

Speaking of wheels and tires here's a photo of the truck tires used in the largest salt factory in the world. (the largest salt buyer form this factory is Canada for their roads in winter) The factory is in Guerrero Negro BCS Mex. (Baja). I was told that the tires out last the steel rims due to salt corrosion !! Amazing !! That's me in the wheel last month.......Bruce

Attachments

Yes I have bolts, ordered two full sets, just in case. A whopping $7 each.

Copy the idea to add two bolts then give it a whack. Or two.

Given that the CVs are not worn or damaged, and then thinking that maybe fresh grease might be a good idea, Can they be cleaned in-situ, then repacked?

If the boots aren’t torn, and you aren’t going to replace them, I would just bag the end to keep dirt out while you are working on it.

If the boots are torn and are being replaced, then I would disassemble each joint, clean them and then put them back together, with new grease. They aren’t hard to do, but a little tricky. They can go together 2 ways, only 1 which is correct. Get it wrong and they don’t move, just bind up.

What Rick said ^^^^

Re your CV shafts:

Remember the words of my old Uncle Tobin, a 20 year Navy Sea-Bee and veteran of WW II in the Pacific:

"If it ain't broke, DON'T FIX IT!"

Everybody's different, but if I had the CVs free from the car, I'd definitely replace the boots and grease them. Boots are about $40 for 4 of them. Finding the right grease is harder than it sounds, but happiness is seeing nice clean grease in nice clean CVs, hiding under nice new boots. I've got an IM, which means a lot of good things, but which also means I have to R/R IRS boots with some regularity, at least every 2 years.

As far as "if it ain't broke, don't fix it" - that sounds great... sorta' like "If it feels good, do it!" and "what doesn't kill you only makes you stronger".

I doubt it's really how you live your life, though. If you did, you'd never change your oil. I'm seriously hoping the next airplane I get on doesn't ascribe to this philosophy. Got a septic tank? Let me know how leaving it alone works.

A lack of maintenance is what got Kelly in this situation to start with.

@Stan Galat, are your boots tearing? Every 2 years seems excessive, otherwise. Aircooled.Net sells some European ones that are supposed to be better, and include the grease and new bolts.

You know Stan and I are usually in lock-step on many issues. This isn't one of them.

CV joint boots routinely go over 100K miles, even today. My Cayman has 110K on the factory boots, CVs, and axles. Pretty much the same situation Kelly has: a stock transmission position and small arc of travel.

If the boots are pliable and not cracked, leave them alone. If the grease looks clean and doesn't smell burnt, leave it alone. If the balls and cages/races aren't blued from excess heat, leave them alone.

I get your position, Stan, on your IM. The forward position of the trans is great for balance and handling. Not so much good for CVs and boots.

@LI-Rick posted:@Stan Galat, are your boots tearing? Every 2 years seems excessive, otherwise. Aircooled.Net sells some European ones that are supposed to be better, and include the grease and new bolts.

All tube-framed Intermeccanicas are IRS, and they are designed to move the engines and transaxles forward in the car 2" so the CV shafts are "butterflied" and on a greater angle than those in a pan car.

This is fantastic for packaging (more room for exhaust, etc.), and especially for weight distribution - but it's hard on boots. EMPI level boots (and that includes those from NAPA, etc.) last about 2-3 years for me. Yes, they tear.

I wasn't aware of ACN's european boots, but I'll definitely try them. Thanks for the link.

@Stan Galat, I thought that might be the case. Off road runners, using 3 x 3 long arms have that same issue. Are you using type 1 joints?

@LI-Rick posted:@Stan Galat, I thought that might be the case. Off road runners, using 3 x 3 long arms have that same issue. Are you using type 1 joints?

I am. I know bus joints and 930 joints have better boots, but I have a hard time wanting to replace what I've got. I've got a lift - doing the boots isn't a hard job - messy, yes, but easy.

@LI-Rick posted:@Stan Galat, are your boots tearing? Every 2 years seems excessive, otherwise. Aircooled.Net sells some European ones that are supposed to be better, and include the grease and new bolts.

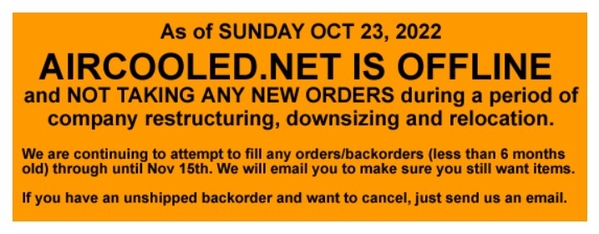

As an aside - aircooled.net has been a bit of a question-mark since John Connelly kinda' stepped away about 10 years ago.

They used to share a building in an industrial park in St. Lake City with Art Thraen, and I actually walked in and got some 10- 15 years ago. Art sold to Justin and Colton McCallister, and they moved the shop up to Idaho a couple of years ago.

aircooled.net's website has shown more and more stuff out of stock since Covid. Today, when I tried to buy the boots I got this:

I'm not sure what that even means, but it can't be good.

Attachments

@Stan Galat posted:As an aside - aircooled.net has been a bit of a question-mark since John Connelly kinda' stepped away about 10 years ago.

They used to share a building in an industrial park in St. Lake City with Art Thraen, and I actually walked in and got some 10- 15 years ago. Art sold to Justin and Colton McCallister, and they moved the shop up to Idaho a couple of years ago.

aircooled.net's website has shown more and more stuff out of stock since Covid. Today, when I tried to buy the boots I got this:

I'm not sure what that even means, but it can't be good.

Wow, looks like another bites the dust.

Idaho is becoming a hotbed of HiPo VW, with Blackline and now RLR both moved there!

@LI-Rick posted:Wow, looks like another bites the dust.

Idaho is becoming a hotbed of HiPo VW, with Blackline and now RLR both moved there!

Agreed. If I had a portable business, I'd take it to TN. Idaho/Montana/Wyoming is the TN of the mountain west.

You could try Raxles down in Gainsville, FL

https://www.raxles.com/ordering.aspx

I got my drive axles from them a looooong time ago and they just keep chugging. I know I re-lubed them once, but that was in the early 2010s.

If it's a standard VW IRS drive axle, or even if it's been upgraded to 930/944 CVs, they should have high-quality boots for you.

On my full Subie I haven’t had any issues with boots. Just saying.

I had no idea John had stepped away. I used to give preference to ordering from them because of John's support of the hobby and because of less concern about the quality of stuff.

Now I check Moore Parts first because of their free shipping.

@Stan Galat posted:I am. I know bus joints and 930 joints have better boots, but I have a hard time wanting to replace what I've got. I've got a lift - doing the boots isn't a hard job - messy, yes, but easy.

So you could change the stub axles and transmission flanges for Bus or 930? Then get some heavy axles and forget about it?

I'd do THAT.

CV joint maximum angularity,

Type 1 is 12 degrees

Type 2 is 17 degrees

Type 4 is 22 degrees

930 is 25 degrees

With the forward position of Stan’s transaxle, he would definitely benefit from more angularity. The type 2 joint is 32mm wide, same as a type 1. A type 4 joint is 34mm wide. They are all the same spline. You can use any of these CV joints with the stock axles, but with the type 4, you will have to cut the shoulder back 2mm on each side. Not really a big deal for a guy with a lathe. I don’t think you could ever break a stock axle on street tires. If you go for 930, new axles are mandatory, as they have a different spline count. You will have to change the stub axles and transmission flanges to match whatever joint you chose.

Thanks for the concern.

I’ve got sway-away axles and Lobro joints. I don’t want to reinvent the drivetrain. I just need “better than Chinese” boots.

The problem is the boots, not the joints.

OK, so the aircooled.net boots were Febi/Bilstein, and are purported to be manufactured in the Fatherland. They're available from S&S Aircooled (who I never heard of before a search), for $17/each.

There are Rein brand boots, supposedly made by Italian elves, available for 6 bucks each, from a place called FCB Euro. $6 is absurdly cheap, and the shipping is free. The only worry is that I've read that Italy has very high end manufacturers and no small number on the very low end. There's nothing in-between. I can guess where on the spectrum a $6 CV boot lands.

I'd give either of them a try next go-around, if I didn't already have boots from NAPA on the car, and a set of EMPIs in the hole.

I'll say that the boots look very nice, no tears, pretty clean, supple. An earlier question was: can you effectively wash out the grease and repack the one CV end without taking it all apart? That is, with the tranny end still untouched, with the service tech recumbent under the car? Is that just a stupid idea?? If you have a nice pan to catch the gunk, can it be done effectively? And I'm hip about how the CVs go together, saw a nice video about that.

Have not had a chance to whack the outboard CV/half-shaft loose yet. Maybe tomorrow ??

"Lack of maintenance" ... ouch ... thanks @Stan Galat for pointing that out. That's not my general approach to stuff, esp'y car stuff, but in this case the evidence is too damning -- me culpa, shoulda checked those castle nuts. That said, I can't help thinking that using the short spline disk hubs + spacer, coupled to that torquey 2332 may have played in to all of this too. I can even throw in several days on a few Tour d'Smos, and I may have asked for more than those parts could keep delivering. [Please recall no less a personage than Stan G. broke his very fine car on the 'Smo, and nobody is ragging on him about sloppy maintenance. Just sayin' ] So blame the 'Smo. And as you can see, by this logic, this is all @Lane Anderson 's fault. Or maybe @Carlos.

@Stan Galat I've bought Rein stuff before, for more modern Porsche, Audi, and VW stuff. It seems to be OK in my book.

FCP Euro is in CT, and started off years ago small. They got pretty big, and are a big sponsor at Lime Rock now.

I also use Autohaus AZ.

Shop around, but I've had good luck with both.

.

@Stan Galat , you may want to give Anthony a call.

He's well acquainted with the IM boot issue and replaces a lot of them, so he may have some advice on sources or remedies to forestall the inevitable.

And BTW, he once put a Berg 5 in an IM (although I think he swore he'd never attempt it again), so he may have some counsel for that, too. I drove the car afterwards, and it was solid as a rock.

.

@Sacto Mitch posted:.@Stan Galat , you may want to give Anthony a call.

He's well acquainted with the IM boot issue and replaces a lot of them, so he may have some advice on sources or remedies to forestall the inevitable.

And BTW, he once put a Berg 5 in an IM (although I think he swore he'd never attempt it again), so he may have some counsel for that, too. I drove the car afterwards, and it was solid as a rock.

Oh, my friend - I'm way, way ahead of you on that.

.... can you effectively wash out the grease and repack the one CV end without taking it all apart? That is, with the tranny end still untouched, with the service tech recumbent under the car? Is that just a stupid idea?? If you have a nice pan to catch the gunk, can it be done effectively?

@El Frazoo posted:.... can you effectively wash out the grease and repack the one CV end without taking it all apart? That is, with the tranny end still untouched, with the service tech recumbent under the car? Is that just a stupid idea?? If you have a nice pan to catch the gunk, can it be done effectively?

If you insist on repacking the outer joint, why in Heaven's name would you do half the job?

If you still insist on repacking just take the axle out. It's 6 stupid little bolts.

You should either leave it alone or do the whole enchilada.

@DannyP posted:You should either leave it alone or do the whole enchilada.

I agree. With new boots? You know... since they're less than 10 bucks each?

Couldn't help myself.

.

@Stan Galat posted:....Oh, my friend - I'm way, way ahead of you on that...

So, are we due for an update, or did I just miss the memo?

.

You've missed nothing, Senior Mitchster.

I'm not very big on starting "I'm gonna' do this" threads. I'm more of a "I did this" kind of guy, because nothing about this hobby moves very quickly, at least when you are a pedant.

... and it's a good thing too, in this instance. The boilers of progress move the train slowly. Unbelievably slowly in this instance. Glaciers move more quickly than this 5-speed has gone together. This cake has been baking for several years.

When we started the Berg-5, I didn't know what I was going to put it in - but I got the feeling the Bergs weren't going to be able to keep the wheels on GBE forever, and if I wanted the thing for anything ever, I had better get going on it sooner rather than later.

A catastrophic failure in my rear suspension at the Tour de Smo this year was enough to push me over the edge into something I wanted/didn't want to do (put the 5-speed in this car). We're redoing the rear suspension into a coil-over setup, which is required in an IM for the "size-giant" Berg nosecone to fit.

Regarding the unending delays - at first, I was in no hurry and said so, which in the language of small business means that continental drift moves more quickly. I knew that and was OK with it.

But then came Covid, then shop help issues, then solar flares, then the zombie-apocalypse, with everything aggravated by "not being close by" issues, and now a 3rd gear that appears to be more rare than shards of the one true cross.

This transaxle has had issues like a Jr. High girl, but we've moved through the seven stages of grief, and I'm at acceptance. I'm on the front burner now, but we can't grunt real hard and extrude a 1.39 3rd, so here we are. It'll be done when it's done. "Serenity now" as it were.

Hopefully, I can actually enjoy it before my eventual atrophy and demise.

whole enchilada ... I like enchiladas OK, prefer burritos. I guess I'm at one of those stages Stan refers to -- not sure which one tho. And the problem just keeps getting bigger and bigger. Started with: bearings must be bad, so order bearings, learn how to do that; then the hub spline turns out to be what is REALLY bad, so order that; then stupid CV bolts won't undo, totally bung-up one trying to undo it, so get the special tool and new bolts, and learn how to cope, study CV joints and what they are all about. And now i'm looking at a rebuild of the entire half shaft, and have not even yet attended to the bearings, which will be last to do, as other shyt keeps piling up in the way. So, just eat the enchilada and quit whining.

... which says nothing about the issue with my transmission, wherein I found a rather large portion of a gear tooth in the bottom of the case when I changed the tranny oil this spring. Can't move out on that until the rear wheel works again. I have a plan for that in the works, but can't move out until ... and even that may be fraught with uncertainty, as Stan also points out: getting parts. Seems I will need at least a ring and pinion set, and beyond that I can't say. My info is that getting these parts might take months.

Atrophy and demise?? Have not addressed that problem in any serious way yet . . .

When my boots were bad, instead of dealing with the mess of replacing them, I bought new axle shafts with the lubed CV joints and boots already installed.

@El Frazoo posted:... which says nothing about the issue with my transmission, wherein I found a rather large portion of a gear tooth in the bottom of the case when I changed the tranny oil this spring. Can't move out on that until the rear wheel works again. I have a plan for that in the works, but can't move out until ... and even that may be fraught with uncertainty, as Stan also points out: getting parts. Seems I will need at least a ring and pinion set, and beyond that I can't say. My info is that getting these parts might take months.

Atrophy and demise?? Have not addressed that problem in any serious way yet . . .

Kelly- if you can find some locally to rebuild your transaxle he will probably have a stash of used parts.

I have a local resource lined up for the tranny work. The info I relay is from that source: parts are taking a long time to arrive, depending on what you need.

And I understand about just punting on the refurb of existing CV parts, and just buy a half shaft ass'y all ready to go. $100 +/-. Some on-line videos on this topic recommend that. My thought is that we're talking less than 20,000 mi on the CVs I have, so they should be OK, right? I have no reason to suspect otherwise. OTOH . . .

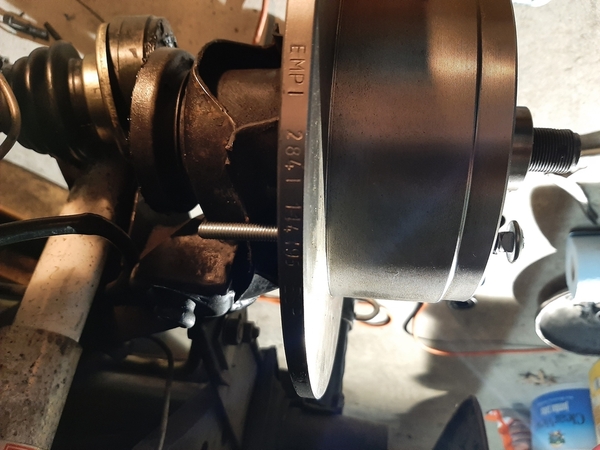

I had no reason to suspect my original parts. It just seemed a lot easier to replace the whole assemblies,

SITREP # ???, but who's counting? Couple of things. First is undoing the funky 12-pt spline bolts holding the CV ass'y in place, six each end, has proven to be a couple day job. Not 8 hour days, tho. The problem was to secure the axel against the torque need to loosen those bolts. Finally figured that one out, see pics. I slipped on the new disk and ran a long bolt thru the tapped lug bolt hole, one long enough to interfere with the suspension arms. Tried the pipe wrench on the bare shaft, that did not really work -- wrench slipped, and too many hands needed. Also tried vice grips, but that was very cumbersome and did not do it either. I tried to get a long threaded metric bolt that would thread in like the lug bolt, but local hardware could not get the right thread. So just got a slightly smaller one the would poke through without threading. Worked like a charm. Half shaft and CV joints removed. Now about those CVs: removed the circlips on each end and figured the CV cage and such would just come right off. I'd clean it all up nice and purty, and regrease, good as new. Well, no. The very end of the shaft outboard of the circlip grove appears to be to big to let the CV thingie come off the end. So, I'm stuck on that one. Must be missing something really important. [If you look closely at the first picture, the CV ass'y end at left is wiped off a bit, and the end of the shaft is just visible, and looks to have tiny gear teeth around it, just outside of the circlip groove. These are too big to slip past the CV bearing inner part. Curious, as I see no other way to take this contraption apart.] Looks like I'll be buying a new half shaft ass'y, and going full monty. Further: one end of the CV is all floppy and wiggly, kinda like I would expect. The other end is really really stiff. it moves, but you have to really push on it to articulate. Hmmm . . .

As I am going all out on this tear-down, ( the new brake disk of course, plus now the CV ass'y, AND new bearings), I need to get the old bearings out. Outer bearing, no sweat at all. But I am stuck on the inner bearing removal; smacking it with a drift and hammer from the outboard end via the little cut-outs in the strut bore isn't moving that sucker an iota. I guess there's a special tool, gear puller sort of thing, that would work, which of course I do not have. Does anybody have the answer to this riddle? The required special tool? a shade-tree work-around that actually does work? Need help ASAP.

Attachments

@edsnova, you must have solved this riddle, got the tools?? Or maybe you never tackled the IRS config??