Inner bearing: I may have doped this out, stupid me. The inner bearing is captured with a circlip and I sorta forgot about that. I should not work on the car so late at night . . . anyway, will extract that ring clip and then see if I can move that bearing. Disassembling the CVs is still a mystery.

I think you made getting the cv bolts out much harder than it is. To keep the flange from turning, set the parking brake. Loosen the transmission side first, than loosen the drive flange side next.

After removing the c clip, the CV is a slip fit to the axle. The reason you can’t just slide it off is the splines are buggered up. Clean the ends, then use a file and clean up the splines. The cv’s should be able to float on the splines. Aftermarket axles, such as Swayaway, have no inner stop and much longer splines.

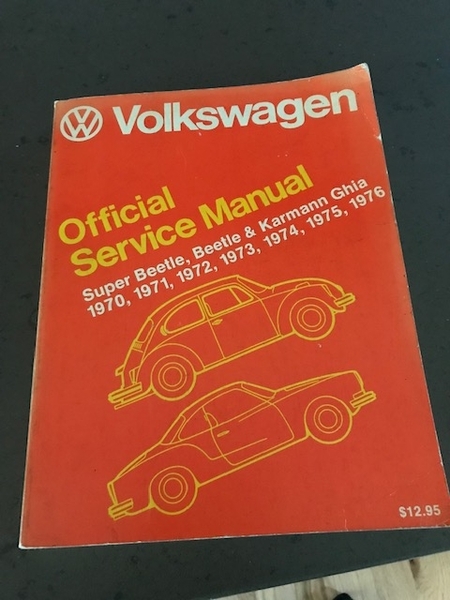

@El Frazoo, btw, do you have this:

The Bentley manuals show just about every VW mechanical procedure you are likely to need on a speedster. They are still printed, but you can probably find a nice used copy on eBay for less $$.

Attachments

I just checked my Bentley manual (see above and well worth the $$) and the one and only time I decided to remove the CV joint from the axle shaft I removed it with a shop press - The same way the Bentley manual recommends. IIRC, mine was stiff going over the end splines, too, and rather than beat on it I just used the press. That was decades ago and after rebuilding the shaft and getting everything all back together, I decided that it was such a major PITA that I've bought new, assembled, driveaxle shafts ever since. At $100-ish each for new ones, it's well worth your time to just get new ones. Ask if they'll take the old ones back, too.

I replaced the stub axle bearings on one side of my car when in SC one year as the bearings began to growl on that side. Removed the drive axle and then the entire diagonal arm and took it to a local shop to press the old bearings out and the new bearings in. Had it back later that day and in by evening.

Unlike Gordon, I would rather use the old German axles. The new axles you get are likely to be made in China, of inferior quality metal. Years ago, I turned the inner stop off a pair of stock axles, and they are hard! I also shortened a pair of Latest Rage axles for a bus into bug transmission conversion, and they cut like butter. Just saying.

I see no point in replacing things that don’t require it. Seems wasteful to me, maybe I have some of the old Yankee thrift.

... trouble is, These parts are likely not "original old German", as this car is a turn=key replica from JPS, so a good bet would be All the parts are EMPI or similar. But just for fun, let's say I'd like to order a new good German or similar quality part, where would I do that? Locally my NAPA and Advance shops list these out on website, but do not have and cannot get. Jbugs likely has, so need to call them, but then need to wait yet some more until they arrive. Groan.

As to a rebuild of the ones I have, sounds like I need to take a file to the slight protruding end of the drive shaft and get it to size so will pass the CV ball cage ass'y. I could do that if that is the way. I'm also of the old school, where if it ain't broke just clean it off and reuse it school too. But everyone just seems to say: shyt, go buy a new one and don't get all greasy. BTW, if I really have real VW parts, would there be a V-over-W logo embossed thereon?

Parts apparently available on Amazon, exact same thing (US mfr , GSP??) as NAPA would provide. $68/ea -- too cheap?? Well we'll see. On the one I took out, Why would one end be really floppy loose, easy to wobble, the other stiff as can be? Fried grease in one of them? Everyone mentions the need for high temp special CV grease. I have the Red Line product supposedly good for 800F. The grease that is in there is black as night, and there is plenty of it, and does not smell bad, so ??? Meanwhile I ordered two of these from Amazon. And will have an adventure on my bench with the one I took off -- will see if I can get it apart while I wait for new stuff. This "project" has turned into a real adventure. A learning experience. It's a hobby, right?? If/when I do the other side, at least I'll know how to do it. Right now all I intend to do there is be sure the castle nut is tight enough. We all remember about that castle nut right? It's where this long and windy road started.

I’d guess JPS bought wrecked bugs and used as many parts as possible to save money. He probably put new CV boots on and didn’t even clean the joints.

Those do look like original VW axles, but I certainly can’t be sure.

@Gordon Nichols posted:I just checked my Bentley manual (see above and well worth the $$) and the one and only time I decided to remove the CV joint from the axle shaft I removed it with a shop press - The same way the Bentley manual recommends.

What am I missing here? I'm intimately familiar with this process, as I do it oftener than anybody here, I'd imagine. The CV joints slide on the axle shafts easily, and are retained only by a circlip. I'm confused where the press comes in.

Regarding axle-shafts and the quality of aftermarket stuff - I agree with Rick in principle, although I think coming up with OG axles-shafts (or any other parts, really) must be considerably easier in Long Island or Long Beach than in Buttscratch, Outer Flyover, USA.

Given that Kelly is struggling so very mightily with this, and given that he definitely doesn't have OG shafts or Lobro CW joints anyhow (John Steel would never spring for such frippery), I'd also recommend just buying the East Asian shafts and joints already assembled. I understand thrift, but I also understand that not everybody has the desire to use CV grease as a body lotion.

I'm not buying an assembled shaft, but I've never struggled at all with this.

@Stan Galat,

These factory axles are available on TheSamba classifieds, cheap. The reason I think JPS used them as they came free on the junk cars he is buying.

Rick, you might be right in your assessment. I know for certain that JPS bought old VWs wherever and whenever he could, likely still does. Napolean's hat and other fun stuff at the back where the works hangs on are from a '71 beetle -- my title says so. My tranny is supposed to be new, or at least newly rebuilt, as is the engine and most other stuff. As to the axels, what you say may be the exact case. Maybe I have two 1971 VW half-shafts, never seen the light of day since made. Perhaps I'll find out. Stan: I was, as expressed, completely flummoxed when the clips were off and the CVs would not budge off the shafts. Will report out later when I see how to get them apart. Might throw in a picture or two.

A Further thought, as my time spent working in DoD R&D involved finding out why a test flight or other experiment failed, often dramatically. I have witnessed and have been, to a certain extent, responsible for manufacturing great balls of fire and lots of unintentional shrapnel, and in such cases it is always a must at the Failure Review Board (FRB) to locate the root cause. When you pick up all that shrapnel, its often not too clear what led to the demise. So . . . If Rick here has put a finger on it, could a bad CV bearing have ultimately led to the observed outer failure, namely a loose castle nut and a nearly worn smooth brake hub spline? Do those dots connect? Back at the FRB, we called this the Failure Tree, which often displayed not as a tree but as what we called Fish-bone chart. Lots of proposed root causes as ribs of a fish, feeding in to a central spine that would lead to what you observe at the end.

... to be continued ...

To answer your last question: NO, the CV joints can't loosen the big nut. No, they can't cause the failure you have.

@El Frazoo All I hear is "blah blah blah", and then some more "blah" to top it off.

Am I being harsh? Maybe just a little.

I told you to leave the darn CV alone. LI-Rick told you. Uncle Stan told you. Those two guys I respect mightily. You're just like a few others on here that can't seem to leave things alone that really aren't a problem.

But no, you're gonna do what you're gonna do. Which is fine. Just stop being an "ask-hole" and wasting everybody's time when clearly you are not that mechanically inclined.

Do NOT file the end of the axle to get it apart. It did go together that way. This job is above your paygrade.

Please. for the love of anything at all, pay somebody to do the rest of the job. You know, before you really break something. Or worse, you hurt yourself or someone else.

You say you've got a tranny guy. Let him do the whole thing. Please.

From the GSP website --- sounds good,, is it true, or just fine marketing gibberish? The VW Beetle part number is: NCV72998, pretty sure. Read on:

"GSP New CV Axle's are made from only the finest materials using premium steel, boot, and grease. GSP CV Axles are designed to exceed the original equipment specifications for a trouble free ride."

https://www.gspnorthamerica.com/product/ncv72998

HEAT TREATED

All GSP Axle components are heat treated to the highest standards to provide premium strength, increased tensile, and extended service life.

QUALITY CONTROL

All CV Shafts undergo an extensive quality control process to ensure a long and trouble-free performance.

PRECISION FITMENT

Machined Splines for precise OEM fitment

PREMIUM MATERIALS

GSP sources only premium raw materials to manufacture their products.

Get into gear with GSP’s most popular product line. GSP CV Axles are the one you can trust when you want reliability and quality from drivetrain replacement part.

GSP Extreme Duty (XD) Axles

Constructed with TPE and CRR for a tougher, temperature resistant boot

Durable stepless ear clamps for consistent pressure to ensure proper seal

High quality, temperature resistance grease with higher frictional and abrasion resistance

Over 24 SKU’s

Warranty: limited lifetime

Danny: nope. But thanks for caring.

... plus at this point the car can't be moved, and the tranny guy does not do house calls. What you suggest is not how I roll, which maybe I thought you understood.

@El Frazoo posted:could a bad CV bearing have ultimately led to the observed outer failure, namely a loose castle nut and a nearly worn smooth brake hub spline? Do those dots connect?

No.

I'm a simple man. If a thing walks like a duck and quacks like a duck, it probably isn't a duck-billed platypus.

Your hub rounded out because your nut was loose. I'd have to look at the pictures of your splines again to see if they're worn - but a lot of times they aren't. Even the best cast iron is no match for hardened splines, and the cast iron on your brakes was likely not German steel.

I wouldn't have touched the stub axle if the teeth weren't worn, which would have made this entire thing a one hour job, with 30 minutes of that being locating the parts and pushing the appropriate buttons on the cormpooter.

I'm not sure at what point we decided the CV joints needed anything at all, except when one of the balls fell out, which is not a failure (it's the normal nature of the thing). I recommended new boots, but I was superimposing the way I do things onto the way you're doing them, Kelly. I take it back.

At the current rate, we're going to be talking about diagonal arm bushings soon.

Stop the madness. At this point, just buy cheap axle assemblies, and figure you're going to put in a new stub axle and bearings. Or leave the stub axle alone, and just replace the axle assembly, assuming you haven't irreparably harmed anything back there.

"First, do no harm".

This is a great thread to follow on a cold Winter's afternoon (after putting the winter wheels and tires on two cars; loading up the wood box to keep the two woodstoves going; and keeping our young border collie occupied).

Some days, life is good.

Add to that, a nice hot chocolate while sitting by the wood stove.

SITREP # ??+1: Just FYI, those who get bored easily and have seen it all, heard it all and can't take it anymore are invited to check one of the other threads. There are many.

Old CV/axel ass'y: I filed down the bunged up end a little and got the CV bearing thing out, and cleaned. (How does that little end of the axel get "bunged up?? another puzzle) The CV innards looks just fine, and I can see a tiny wear spot where the balls bear. Cant detect any actual wear, just a little shiny spot. I will attempt a refurb here: clean and regrease. Because: why not? The boots look pristine. Cant tell who made these half shafts.

New CV/axel ass'y: two of same on order, see info on the parts above, GSP. Arrive next week, says here.

Inner bearing: popped the circlip, knocked the bearing out from outside. Says "HUNGARY" on it. Seems to be fine, but I have new FAG so will use those. Busy cleaning up all parts.

Stan wants to know why. I could say, well shyt, its winter, why not? I wonder if he ever said such a thing. Oh wait, I think he's doing that right now. But Nevermind, this is not about Stan . . . Here is the basic thought train here, by way of review for those who tuned in late. Car got a lot wobbly during recent Tour d'Smo, generating a mild WTF?? Left rear tire now rubs the body a little and when you grab and shake the wheel, it shakes with some play, makes noise. So: must be bearings. Attacking the castle nut, I find out it is WAY loose. I know that's not good, but cant noodle out why it might be so. That nut is supposed to be torqued to bejeezus and back and develops a terrific axial load on the spacers and bearing inner races that carry the stub axel. How does that stack get un-tensioned during use? Again, I dunno, but clearly it did. And the nut did not move as it's captured by the cotter pin. So the stack-up moved/shrank a smidge. How? again: dunno. Not tight when built? Maybe. The eqt as found has a final outboard spacer under the castle nut because the disc hub has a short spline vs the stub axel spline length. This spacer shows some distortion upon close inspection. Not sure what to make of that. Upon removal of brake disc I discover the spline there chewed to almost nothing (see picture). Stub axel wiggles a tiny bit laterally (bearing wear??) and has a bit of end play. Wiggle still suggests bearing, and as best as I can tell a little endplay is fine. So Order two new disks with longer spline, obviating that outer spacer. Next, Gotta get to the inner bearing which means gotta undo the half shaft. Outer bearing just sorta came out easy peasy. I Totally screwed up the CV unbolting using a 6 flat allen rather than 12pt spline wrench since did not look and did not know. My bad. Vice grips saved the day as I tottally f***ed the one socket bolt socket. I got the right 12-pt tool, and Bob's my Uncle. Internet Videos show the half shaft when unbolted at outer end just swings out of the way. Not that I can see. So I must undo the inner CV flange and take out the whole thing. At this point: Rebuild or buy new CV drive shaft ass'y? See above, as that is where I am.

Usually it's one or more of three things that cause this failure. Maybe there are more, but these are the most common:

1. Not enough torque applied.

2. Irregularity or uneven stack of spacer, bearings etc.

3.VERY IMPORTANT: Cheesy "spacer/large flat washer" that simply crushes out because it's not made of sturdy enough metal. This spacer comes in the cheap seal kits and should be thrown out and not used. Even 0.001" of crush here will destroy the hub splines.

My money is on #3. I'll send a picture.

Txs

Tomorrow is Black Friday, and mine will be a bit of that, cleaning up the bearings and such from some really black grease. I hope all have had a pleasant Thanksgiving and are properly fed, as that seems to be the main idea. All good here on that score. I now have all parts needed to reassemble my right rear drive train: new CV axel half shaft, all bearings, new brake disk. I hope it all fits up right. The GS-P CVs arrived and remain to be carefully inspected. Here's hoping that the website advert (see above) is correct, despite the fact that these items are Hecho en China, because, well, isn't everything?

As to the "root cause", the speculation above suggests that the poor spacer used in original lash-up is it. Could be. I enclose a picture, as promised, of said spacer where I can feel a slight mushrooming of the edge of the piece, maybe almost visible in the picture. It can be felt with a finger. So it deformed a little. And a little is all it takes to loosen the tension/compression in the assembly created by tightening the castle nut. So, the new brake hub has a longer spline, and no spacer is needed, says here. Should be better. Hope so.

Attachments

So what have I managed to get here? New bearings are FAG, and says made in Korea. New brake disk is EMPI, made in China of course, because could find nothing else. Jbugs is the supplier. They really do seem to have at least one of everything. CV half shafts are, as mentioned, also made in China, ordered from Amazon. If any of these parts are made in the USA, or Germany, I was unable to locate such a part. Lots of local suppliers (e.g., NAPA, Advance Auto) list these parts on websites, but in fact do not have them, cannot get them. Just FYI.

@El Frazoo posted:If any of these parts are made in the USA, or Germany, I was unable to locate such a part.

As I mentioned some time ago, CB Performance has GKN/Lobro CV Joints. Made in Germany.

You do you, Kelly - but we're trying to get you decent parts.

Attachments

Stan: I'm dancing as fast as I can. And I checked with CB about all these parts. Must have asked the wrong question.

.

Things are just getting curiouser and curiouser.

My dad was born in 1904 and died in 1973.

I'm wondering how I would even begin explaining to him that I'm driving a fiberglass copy of a 65-year-old German car and that new parts for it come in a box stamped 'Hecho en China'.

He'd probably tell me I'd be fine as long as nothing on it was made in Japan.

Growing up that was the slur on products outsourced . No way jose san

@El Frazoo posted:Stan: I'm dancing as fast as I can. And I checked with CB about all these parts. Must have asked the wrong question.

I can see that. Nobody is going to sell the entire shaft/CV joint/boot setup as an entire assembly with anything but Chinese parts.

I suspect it'll be fine for your usage.

@IaM-Ray posted:Growing up that was the slur on products outsourced . No way jose san

It wasn't just the products, Ray. A lot had to do with Japan's treatment of captured troops in WWII.

My Dad's lawyer was a Navy fighter pilot, shot down and captured by the Japanese during the battle of Bataan. He was a strapping 6'4" 250 pounds when he became a pilot. He was also part of the March of Bataan during the war. 70,000 prisoners started that 65 mile march across the Philippines and around 15,000 died along the route. He was a survivor, but when finally rescued he weighed about 80 pounds and had been sterilized by his captors. He later married the nurse who was assigned to care for him and after a long, recuperative hospital stay they made it home to Massachusetts and he lived into his late 70's with his wife and their two adopted kids. He wrote a book about his experience, but it's quite difficult to read.

It's things like that, made it hard for people living in the 1950's - 1970's, who were much closer to WW II than we are, today, to buy Japanese products.

@Gordon Nichols, what’s the name of the book?

My grandfather sailed on the USS McCalla throughout WWII. He wouldn’t give a Japanese person the time of day. Didn’t hold any grudge against the Germans.

@LI-Rick posted:My grandfather sailed on the USS McCalla throughout WWII. He wouldn’t give a Japanese person the time of day. Didn’t hold any grudge against the Germans.

My dad was the same (Army Air Corps South Pacific). I suspect it's easier to treat others badly if their skin isn't the same color as yours, but that wouldn't explain Nanking.

Japan had a very nationalistic military during that time and it was touch and go whether they were going to let the emperor surrender. Maybe that nationalism contributed more to the cruelty than did the color of the prisoners' skin.

In any event, my dad loved and sponsored the citizenship of many folks from the Philippines. He didn't have any kind words for the "Japs."

Our history in the U. S. doesn't give us a pedestal to stand on considering our massacres of American Indians or our enslavement of other people of color. I suspect all nations are capable of atrocities, and the real question is how we avoid falling back into those attitudes so prevalent in the "good old days."

I know my dad's prejudice would melt if he'd lived long enough to know his 2 little Japanese-American grandkids. Nobody could resist those little charmers.

@LI-Rick here is Joe's obit, and I was wrong about his age when he died. According to the Obit he was 93 when he passed. God made one tough man when he made Joe. I also found that he piloted a Corsair fighter-bomber when shot down.

@Gordon Nichols, thanks. I'm going to try to find a copy at a reasonable price. Amazon has one at $150!

@Bob: IM S6 posted:It wasn't just the products, Ray. A lot had to do with Japan's treatment of captured troops in WWII.

Well I guess your much much older than I am so I missed that part of the history lesson ![]()

.

Wartime sentiments notwithstanding, my dad's product advice was, for the most part, hard-nosed and practical.

In the decade or so after the war, when Japan industrial production was still rising from the ashes, the US market was flooded with cheaply-made Japanese consumer goods that were often half-hearted copies of stuff made in the US (back when stuff was still made in the US). And those products were almost always genuinely terrible. At the time, the Japanese reputation for shoddy workmanship was well-earned and enduring.

But, I posted the previous comment to remind myself how completely times can change.

Partly as a reaction to how their products were being received in world markets, Japanese industrialists resolved to turn things around and set about doing that with a vengeance. It would be a while before the efforts of folks like Mr. Honda and Mr. Toyoda would make ripples on our shores, but they eventually did. Our industrial heartland would never be the same.

I've posted before about a cross-country trip I took in 1967 in one of the first model Toyotas to be sold here in any quantity. It's design was still strongly influenced by what was selling well here then. Front bench seat. Three on the tree. Ford Falconesque styling.

But the damned thing made it coast to coast and back without a single door handle falling off. The temp gauge didn't budge a notch all the way across the Mojave Desert in July. The effin' clock still worked.

It was starting to look like we'd have to find new things to make jokes about.

.

@Sacto Mitch posted:.

It was starting to look like we'd have to find new things to make jokes about.

.

And then along came the Renault LeCar! Lol

@LI-Rick posted:And then along came the Renault LeCar! Lol

I owned a Renault Alliance, purchased used with 2500 mi. after it was named MT’s “car of the year”. The timing chain ground a hole in the block before the odometer rolled over to 10,000 mi.

It was the single worst automobile I’ve ever owned, including an endless string of $50 cars I drove while building/storing my “street machines” back in the very early 1980s.

That excruciatingly bad Renault held the record for my most disappointing vehicular purchase until 2002, when I had the misfortune of ordering and buying a car from John Steele at JPS Motorsports.

Both cars proved the adage that you don’t always get what you pay for, but you always pay for what you get.

My first car was a Renault Caravelle and it inspired my aversion of French cars, as much as I might think I like them.

In exchange, I tolerate the distain the French have always afforded me during my clumsy tourist excursions.

gotta love the French...have no desire to go there