I've been hunting for oil leaks (eg mentioned here) and have been successful with some, but some were untraceable. I got smart and bought some of that UV dye that you pour into your oil and then trace the leak using a blacklight/UVA. We (father and I) traced it to two places: (1) the cover to what I think is an oil sump pump? (2) an opening for which I don't know the purpose. We thought their gaskets were meager/thin (pictured), so we cut out gaskets from a gasket material sheet we had lying around.

Now it's super leaking oil!! Both places but especially the sump cover.

Perhaps the gasket material is wrong for this use? I don't know the specific product info, but it's paper-like, please see the photo. Should I change this for a rubber material? Or buy gaskets from the manufacturer? I'll have to do some investigation to figure out what motor and thereby parts these are...

I should note that one of the 4 bolts for the square sump lid was loose and its hole was kinda stripped (we believe from before), so we actually tapped that hole and used a larger bolt there. For that reason, we were careful not to *super* tighten the screws, perhaps that has something to do with the leak? Perhaps this means the layer I mention at the end of this post isn't as tight as it used to be either.

Speaking of, I was thinking perhaps the gasket material shrunk after being pressed / heated, so I just tried tightening the few bolts I have ready access to, I noticed that these bolts felt a tad loose. So I'm going to do the whole pulley removal effort (discussed in that link above) again to access and tighten the top 2 bolts of the square lid. But it's probably wishful thinking that that'll do it. Probably should change the gaskets while at it if that's what's recommended...

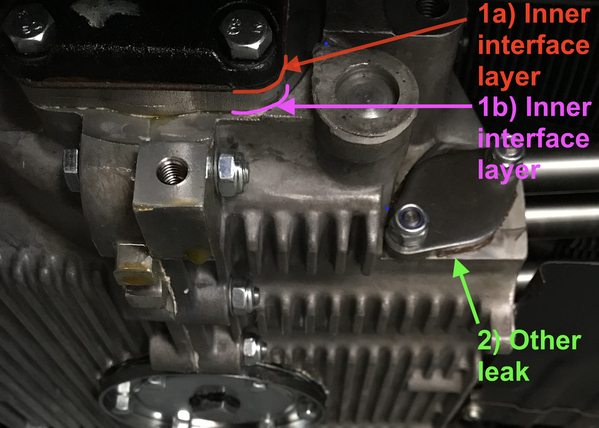

Last but not at all least, I think the sump has two interface layers: (1a) the outer layer we serviced (1b) but there's an inner layer, see the photos. Seems like the inner layer might actually be the main leak. But it wasn't readily apparent how to remove the intervening plate to get to this layer. Any tips on that would be appreciated (I'll try to figure out what type of motor this is, hopefully someone here's familiar or it's a standard setup).

Any help or ideas would be much appreciated!