I saw the posting. I want to see the execution.

Attachments

edsnova posted:I'll really love seeing what you fab up to allow for scheduled preventative maintenance on that engine, nestled as it will be amidships and (presumably?) with its dipstick, oil fill, alternator and thermostat hard against the firewall.

most of it is accessible but we've added a bit more freedom with removable supports

here in India it's a bit difficult to find parts for imports on such short notice, i managed to find an alternative to beetle headlights that are nearly a direct fit. They're off of a mid 2000s "hindustan ambassador", a car that is basically a Morris Oxford series III (1956-1959) that evolved and remained in production in India until a few years ago. It was commonly used with bullet proofing by politicians and military personnel.

here in India it's a bit difficult to find parts for imports on such short notice, i managed to find an alternative to beetle headlights that are nearly a direct fit. They're off of a mid 2000s "hindustan ambassador", a car that is basically a Morris Oxford series III (1956-1959) that evolved and remained in production in India until a few years ago. It was commonly used with bullet proofing by politicians and military personnel.

I'm building this at home in a place called Goa, which is basically a coastal tropical tourist destination. It's quite difficult and slow when work can't be done in house as lathe shops are slow and unskilled. when my partner for these projects, Nigel, went to a bigger city, he gt as much work and sourcing done as possible. the running gear is all d16b Honda, basic suspension arms and hubs from a honda but the upper end is all custom. going for a pushrod suspension because why not.

I managed to find these Watanabe wheels in a scrapyard for $200 and restored them as far as I could, I plan on making a steel wheel widening jig to give that a try aswell.

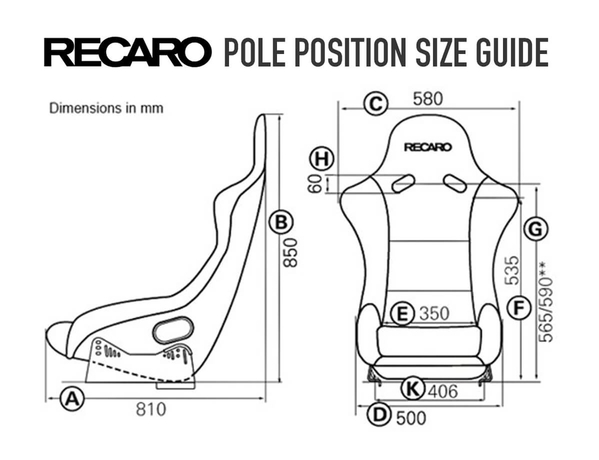

I wanted o do something different with the seats. I started with drawings of recaro pole positions, cut the sides on a computerized hot wire cutter and refined it to something close to what i wanted.

Im trying to make them like Singer seats without headrests. a little filling is needed to restore the symmetry but it's still in the pre mould stage. plan to make them in carbon fiber.

hope you guys are enjoying the build so far. I'm not sure if it classifies as a replica anymore, seems more like a 356 inspired custom car.

Attachments

Woah in Goa.

Dude (dude?) you are absolutely impressive.

This is pretty amazing to watch. Your ambition in the face of some serious obstacles is inspirational.

Necessity is the mother of - a fantastic project such as this.

Wow.

Bob you should plan a Goa trip and go inspect the build ![]()

Thanks guys, do get in touch if you're in town.

I kind of gave up at one point, I think it was just too much for me to handle alone, now things are moving quickly and we should be able to finish within our deadline of 3 weeks if we don't sleep at all.

we began with fender flares

then began with the inner frame work

then began with cutting the body

now its time for the latch mechanisms and other little things

Attachments

This is really amazing to watch come together. ![]()

this week we worked on the interior panels and latch mechanisms.

We also test fitted the headlights and we hand built the horn grill too

https://www.instagram.com/p/Bv..._button_share_sheet/

we wanted seats like the singer 356 without a headrest so we took the profile of recaro pole positions, cut them down and made a mould. then made them in carbon fiber we also restored our wheels, a set of watanabes I bought from the scrap market. theyre real 2 pc wheels

we also restored our wheels, a set of watanabes I bought from the scrap market. theyre real 2 pc wheels

Attachments

we wanted seats like the singer 356 without a headrest so we took the profile of recaro pole positions, cut them down and made a mould. then made them in carbon fiber

Thanks for sharing how you used the drawings to get profile and produced a mold. What type of foam did you use for your mold/mould? And why did you choose carbon fiber instead of fiberglass?

This project is packed with unique engineering ....amazing!

Todd M posted:Thanks for sharing how you used the drawings to get profile and produced a mold. What type of foam did you use for your mold/mould? And why did you choose carbon fiber instead of fiberglass?

I took these drawings, traced the outline and gave it to my local thermocol cutter to cut.

It's a bit to difficult to post all my pictures here and the browser freezes on my phone when it sees all the pictures so you could watch the progress in more detail here.

https://www.facebook.com/therustycashew/

we used carbonfiber to give it that wow factory and to showcase the work we do.

Attachments

Just, wow.

The_Rusty_Cashew posted:we used carbonfiber to give it that wow factory and to showcase the work we do.

Dude.

You went way past "wow" some time back. You sir, are the man.

Hi guys, it's been a while. I had to stop the project last year for some unforeseen circumstances. The project progressed quite a bit and all that's left now are fluid lines, interiors, paint and wiring.

This is what she currently looks like:

I'm also attaching a video of a walk around in its current condition.

Things will progress on it in a couple of months when my 2 post lift is up.

Attachments

Impressive! Welcome back!