I'm using one in my Spyder and have been looking for any info or opinions regarding how strong these transaxles are. I made the assumption that if Subaru bolts up engines to them that produce over 300 hp, they must be at least as strong as any VW box. The weak points on a VW box is reduced with a Rhino case along with all the other things like welded gears, bigger side plates, more splines, super diff's and so on. I haven't found any articles yet on the Subaru box. Anyone have any sources or just know things ? Just trying to think ahead here..................Bruce

Replies sorted oldest to newest

Bruce, FWIW, we just got a manual 2020 Impreza (with a mighty 2.0 L making 152 HP and 145 lb-ft).

Apparently, to save costs, they carried over their 'old' five-speed in the Impreza, so it just might be the gearbox you're talking about. (All of their other current manual models get six-speeds.)

The car's too new to say anything about long-term reliability but it shifts OK, if a little notchy. Fifth is definitely more 'notchy' than the other gears. Hopefully, that will loosen up a bit in time.

Dunno what will be inside yours, but the stock ratios for this car are as follows:

1: 3.454

2: 1.888

3: 1.296

4: 0.972

5: 0.738

R&P: 4.11

Sacto....I have the same gears as you in 3-4-5. My R&P is 3.90. and 3.16 &1.88 for 1 & 2. Ray has some interesting gearing in his that is different from ours. His is 4.10 R & P, 3.45, 2.06, 1.44, 1.08, .78. A little better spread between gears.........Bruce

Bruce,

There is LOTS of info on the Subaru 5 MT tranny online. Most guys will agree that it's safe to about 350 HP, even with hard launches and occasional track use. 6 speed is more robust, but is slightly larger also, with its built-in oil pump. PPG and Subarugears each make r&r kits to beef the 5-speed up, with escalating costs to match. Every source includes a caveat that no amount of toughening makes the tranny idiot-proof. I quit serious shopping when I read that.

Bruce, I'll submit that you'll be fine. Agree with Jim Kelly. Also, that trans was used with the non-turbo 2.5 which is 165hp all day long.

Given that a bone-stock VW was good to 125hp with no mods, I'll bet you're more than OK with stock. Although, a Quaife/Torsen diff is a good idea.

As for gearing, in a light Spyder taller is not a problem. I push a 3.44 with .89 fourth easily and 147 ft.-lbs.

Jim and Danny.......Thank you for your input. I didn't think about looking at PPG and Subarugears. I will. Rancho built my transaxle. I had them install a new Subaru LSD. It's a sealed unit. It cannot be taken apart. it's welded together, not bolted. Here's a photo of it.

Attachments

You'll be fine. A 5 speed is robust enough to survive in a 350 hp car that weighs 3600 lbs. Your spyder will weigh maybe 1500? It will be super under stressed in your application.

One thing that you should know Bruce is that Subie has a gear set for turbo and a gear set for non-turbo so if your running lots of HP sure you need the stronger gear set but I don't think you will need it. If you are running the box with SGear's reverse R&P then from the front of the car to the back you have the 6th or 5th gear in the nose cone so the oil flows to the back upon acceleration and SGears adds more oil to the tranny to make sure the 6th or 5th does not starve in acceleration and also due to the R&P spinning reverse which may or may not affect oiling pattern.

If you are using the tranny in the regular orientation, as it exists in a subie, I don't think there is an issue at all.

Re My ratios. As you quoted above the ratios I have make the car quite petty and you can nicely row through the gears. I would have liked a 3.91 but in your car with top down you won't hear the engine anyway ![]() Enjoy the unbelievable torque.

Enjoy the unbelievable torque.

There is absolutely zero need to get turbo gears in a 1500 pound Spyder. It is literally pushing half the weight of the original car at about the same or slightly more power.

If you drive like an AH you can break anything. If you drive normal or spirited those gears will last forever.

Ray, the Spyder engine/trans orientation is the same as OE.

Gee, thanks Danny for clarifying that orientation question in an age of political correctness.

Ray & Danny.......Again ! The wealth of knowledge rear's it's head on this site. I wasn't aware of the potential issue of lube starvation on acceleration if the engine was reversed such as when it's installed in a Speedster. Thank you both for your input !

Now I'm reassured that I need not have to think about transaxle reinforcement like I did with the VW unit. Over the years I have learned something about myself. I absolutely hate doing car repairs. Repair of a blown gear box is boring as hell ! Original overhauls are fine. However, modifying/improving and fabrication are my passion ! Everyone has a creative vein in them and this is mine. To me, nothing excites me more than creating something in my mind and bringing it to reality. Not everything I do is a success. Many of my little projects end up in the trash can or over the wall into the hedge if it was particularly ugly. Sometimes I think I should do more private posts on here to get my questions answered and not waste others time but then, for me, I enjoy and value articles of info others post here. Thank you to everyone who takes the time to give me their opinion or suggestions.............Bruce

Bruce your "Many of my little projects end up in the trash can or over the wall into the hedge if it was particularly ugly."

Reminded me of golf and the flying sticks you sometimes see leaving your friends hand when the usuallly calm collected lose it ![]()

Your projects are pretty awesome if they do sometimes take flight. ![]()

aircooled posted:Ray & Danny.......Again ! The wealth of knowledge rear's it's head on this site. I wasn't aware of the potential issue of lube starvation on acceleration if the engine was reversed such as when it's installed in a Speedster. Thank you both for your input !

Now I'm reassured that I need not have to think about transaxle reinforcement like I did with the VW unit. Over the years I have learned something about myself. I absolutely hate doing car repairs. Repair of a blown gear box is boring as hell ! Original overhauls are fine. However, modifying/improving and fabrication are my passion ! Everyone has a creative vein in them and this is mine. To me, nothing excites me more than creating something in my mind and bringing it to reality. Not everything I do is a success. Many of my little projects end up in the trash can or over the wall into the hedge if it was particularly ugly. Sometimes I think I should do more private posts on here to get my questions answered and not waste others time but then, for me, I enjoy and value articles of info others post here. Thank you to everyone who takes the time to give me their opinion or suggestions.............Bruce

The only dumb question is the question not asked on the forum. We all could learn a thing or two from each other. Ask away.

Robert M posted:aircooled posted:Ray & Danny.......Again ! The wealth of knowledge rear's it's head on this site. I wasn't aware of the potential issue of lube starvation on acceleration if the engine was reversed such as when it's installed in a Speedster. Thank you both for your input !

Now I'm reassured that I need not have to think about transaxle reinforcement like I did with the VW unit. Over the years I have learned something about myself. I absolutely hate doing car repairs. Repair of a blown gear box is boring as hell ! Original overhauls are fine. However, modifying/improving and fabrication are my passion ! Everyone has a creative vein in them and this is mine. To me, nothing excites me more than creating something in my mind and bringing it to reality. Not everything I do is a success. Many of my little projects end up in the trash can or over the wall into the hedge if it was particularly ugly. Sometimes I think I should do more private posts on here to get my questions answered and not waste others time but then, for me, I enjoy and value articles of info others post here. Thank you to everyone who takes the time to give me their opinion or suggestions.............Bruce

The only dumb question is the question not asked on the forum. We all could learn a thing or two from each other. Ask away.

What Robert said, Bruce. That's why we're here.

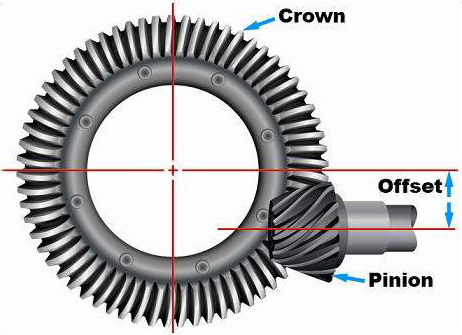

And the Subaru uses a hypoid ring & pinion for strength, like the late VW bus transaxle does. That's how (or 1 of the reasons) such small r&p's survive the power outputs put to them.

The offset allows the pinion head to be bigger, which "provides more contact area and better tooth strength, which (in turn) allows more torque to be transmitted and high gear ratios (up to 200:1) to be used." The type 1 r&p, otoh, is not offset and as such has a smaller pinion head, but is the most efficient. Perfectly fine for a stock Beetle, but (as we all know, some of us oh too well!) it can be trouble when we start putting more power to it.

Have a great day guys! Al

Ps- I always wondered why the Ford 9" r&p was the strongest- look at the size of that pinion head! You'll have to click on the link down below- I can't make it come up as a Jpg file so it's a simple pic.

I'll leave it up to you to research if more offset equals being more inefficient.

I'm going back to bed ![]()

Attachments

Thanks Al....To add to that, here's some other things about Hypoid gears. Back in the days like Model A era they didn't use Hypoid gears. They used an "on-center" pinion gear. Lots of horse power was non existent . These old ring and pinion sets were noisy ! Especially on coast ! Later, the public wanted cars to be "low and sleek" plus be quieter. Here came the Hypoid gears. The pinion gear being offset lower allowed the driveshaft to be lower so there was less floor hump when cars were lowered. Along with this came a much quieter rear axle both in drive and coast. The only problem they had in the beginning was that they burned up a few sets of hypoid ring and pinion gears sets. The found that the cause was the lubricant didn't do it's job because sliding /wiping action when the hypoid teeth mesh under load. What was happening was the gears worked like a "squeegee " and wiped the lubricant off between the gears where they made contact allowing metal to metal contact. They had to come up with a better lubricant that wouldn't wipe off. Hence, Hypoid gear oil was introduced. Trying to keep the cost of the gear oil low the chemical engineers came up with using sulfur as the molecular bonding agent in the oil. This eliminated the extreme wear. Not the sulfur directly but the effect it had with strengthening the bond between the lubricant molecules. It is well known that hypoid gear tooth contact pressure can go over a million pounds per square inch ! While introducing sulfur solved the problem, it introduced another. The sulfur, while being used and stirred up, is in an environment of heat, oxygen and a slight amount water created by the heating and cooling of the air in the axle housing turns into sulfuric acid. This starts to etch the gear teeth and the bearing surfaces. When they found out that this was happening they just increased the frequency of the lube change in the differential.................Bruce

Well! THAT explains the wonderful smell of Dino Hypoid oil. 🤮

Bruce,

Subaru transaxles are strong. Especially in your light car !

Maybe it is more intersting to figure out what the best final drive you are comfort with.

Tire size make also a difference.

Good Luck ! Nice project.