Thinking of starting a winter project changing my speedster over to IRS from a swing axel. Has anyone done this I would like to know the Pro’s & Con’s better handling & ride or not enough to even to do?

Replies sorted oldest to newest

Handling is a hands down win for IRS although some what more maintenance intensive.... You can get advice / information from Rancho Transmission... Just have a firm idea of what you want the car to do and how long you want it to last doing that....

I've had both and really enjoyed both types once their limits were realized..... ![]()

I've done the swing to IRS conversion twice, albeit not on a speedster, but on Karmann Ghia's. I think the handling is far superior and worth the undertaking.

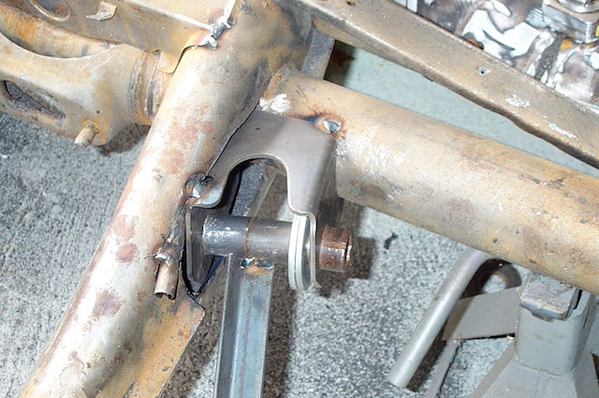

The pictures are from my 1958 LowLight Ghia. I also narrowed the control arms 1 5/8" per side to fit a larger tire under the fender.

I threw together a jig off a bare IRS chassis. You can buy these now from several places to make the conversion easier. A jig is absolutely necessary to get the proper orientation of the IRS bracket. Take your time when fitting the brackets to get a tight fit for clean welding.

I threw together a jig off a bare IRS chassis. You can buy these now from several places to make the conversion easier. A jig is absolutely necessary to get the proper orientation of the IRS bracket. Take your time when fitting the brackets to get a tight fit for clean welding.

I triangulated the rear section for strength and future attachment for a roll cage. I incorporated new shock mounts in the cross bar.

I triangulated the rear section for strength and future attachment for a roll cage. I incorporated new shock mounts in the cross bar.

Those a type 2 CV joints, as they are larger and stronger than type 1. Axles were 16" that were narrowed 1 5/8" to fit the narrowed control arms.

Those a type 2 CV joints, as they are larger and stronger than type 1. Axles were 16" that were narrowed 1 5/8" to fit the narrowed control arms.

This is how you fit a 205/65R15 under the fender of a Ghia. I think a 215/60 would have fit without issue.

This is how you fit a 205/65R15 under the fender of a Ghia. I think a 215/60 would have fit without issue.

Go for it Arden!

Attachments

That is one nice looking Ghia!!

As already said, it's worth doing, as you car with irs will be transformed. The ride will be nicer as well as handling improved, and the only extra maintenance is repacking cv's every 30,000 miles (or is it kms? I forget). Going to the extra trouble to narrow the trailing arms to fit wider tires is also worthwhile; as well as the rear of the car sticking better to the road, it will also look just that much more bad@ss! ![]()

![]()

![]()

![]()

If you can weld it'll be a great winter project. The June '94 Hot VW's magazine has a "how to narrow the trailing arms" article by my friend Bruce. He put 8" Fuchs alloys with 225/50-15's under stock fenders on his Beetle. If you're interested, I've scanned the pages and can post them here (I posted them a number of years ago).

Hope this helps. Al

PS- @LI-Rick- nicely done! (and that is 1 sharp Ghia!) A friend of mine built a similar jig and has converted a number of dune buggies to irs. The Bus reduction boxes were breaking (the new modern offroad tires are just too much for them) and Gerry has converted 4? 5? 6? buggies to bus irs transaxles and reliability has gone way up.

Another PS- @Former Member- What tires and rims are on it now? can you post a pic of your car?

I agree with all of the comments about handling improvement, but in my opinion the key thing here is: "If you can weld it'll be a great winter project. "

Getting the mounting brackets in the right place is crucial to the success of the rear wheel alignment, but as Rick mentions, there are jigs available to make the placement of the mounts really accurate. The key to success is the quality of the welds, so either you weld the brackets in or get a mobile welder to drop by and do it for you. Those guys service trucks and heavy equipment all the time so you should have one near you to google. They can weld them in, right in your garage/shop.

Once those are in and painted, assembling the diagonal arm and spring plates should be straight-forward. You can use regular VW sedan arms and hubs for a 1970 or so sedan and you can go the Type 2 (bus) route on the axles or even go nuts with modified Porsche 924/944 CV joints like I used, but for any engine under a 2,110, the stock sedan axles should be fine and you can get those anywhere, like NAPA.

I don’t think I will have to do any narrowing I have a SuperWide V/S my rims are 17x10 and my tires are 255/40 17s

I love the GHia, it's beautiful, is it finished now?

We do a lot of welding and fabrication at my shop. I’m also pretty lucky to have some Gearheads that love to work on anything with wheels.

i have a 72 coupe under my deck..pretty much rusting away...belongs to my SO(22yrs) her father left it to her oldest son,and there it rots... i am not even gonna try to get involved...,shame...

@IaM-Ray posted:I love the GHia, it's beautiful, is it finished now?

Thanks. That Ghia was sold to Pete Morley in the UK, back around 2007. He got divorced about a year after that and had to sell it. Last I heard I think it’s in Belgium. Pete gets the credit for the interior and engine, I did the rest.

Attachments

@ALB posted:If you can weld it'll be a great winter project. The June '94 Hot VW's magazine has a "how to narrow the trailing arms" article by my friend Bruce. He put 8" Fuchs alloys with 225/50-15's under stock fenders on his Beetle. If you're interested, I've scanned the pages and can post them here (I posted them a number of years ago).

PS- @LI-Rick- nicely done! (and that is 1 sharp Ghia!) A friend of mine built a similar jig and has converted a number of dune buggies to irs. The Bus reduction boxes were breaking (the new modern offroad tires are just too much for them) and Gerry has converted 4? 5? 6? buggies to bus irs transaxles and reliability has gone way up.

@ALB, that is the Hot VW’s article I followed to narrow the arms. I also used a Berg bus into bug intermediate housing, which is a nice piece of kit. Those type 2 transmissions are really tough, I used one in a drag car with a Folts swingaxle conversion years ago.

SWEET Ghia! I love it! Too bad you sold it.

Nice motor too: IDAs, Berg linkage and breather, Mallory distributor.

For some reason after @LI-Rick posted his pictures something looked familiar so I looked underneath my car and it looks like my car was an IRS switched over to a swing axel. I think it might be easier to do than I thought. I’ll get it up on jack stands and get a better look tomorrow

Attachments

It doesn't get much easier than that. Maybe.

Vintage did a lot of swingaxle conversions on the narrow bodies, it is easier for tire fitment in the wheel arches.

If it was my car, I'd buy the already narrowed(they sell them) trailing arms and install them with the widest tires I could get under there.

You may be able to only fit 165/80R15 if you change it back to stock IRS arms. Other guys who have done that can chime in here.

@DannyP I have a Superwide from V/S

Superwide? Just get stock arms and have at it.

When you go looking for the diagonal arm bolts and bushings you will probably find that everyone sells the Red Urethane bushings. Aircooled.net has both the bushings (urethane) and the special pivot bolts. It would be nice to find the German hard rubber versions, but they're exceedingly rare these days (I couldn't find any with a quick search) and the Urethane ones don't transmit too much road vibration.

Back to the question of IRS and standard bodies - unless I'm badly mistaken, if you want to run a standard rear disc brake package with this setup, you'll end up with 4-1/2" rims and you won't be able to slide a credit card between the rear tires and fender. All of the commonly available rear disc conversions (even those advertising as "zero-offset") add at least a half inch per side to track width. There may be rear disc packages that do not add width, but they won't be EMPI cheap. If you want more rubber than you can get with 4-1/2" wheels (and you would), 914 wheels provide a 5" wheel with enough backspace to work.

If you want 5-1/2" Wide 5 wheels, your options are to get steel wheels recentered, or to just get the narrowed trailing arms. As it happens, Ron Lummus Racing has them on sale right now. Figure on $1000- 1200.

Nothing pertaining to these cars is free. You don't always get what you pay for, but you always pay for what you get.

cip1.com sells an OE style trailing style bushings. These are the ones that I used when I converted over to IRS.

Here’s a guy on the samba that narrows irs arms.

https://www.thesamba.com/vw/cl...etail.php?id=1725100

@Stan Galat, as I mentioned in another thread, on my standard body CMC I run rear disks from AC Industries (So Cal). They are advertised as zero offset but did add a very small amount to the track. They milled this small amount from the hubs for me. The cost of these is probably in the same ballpark as EMPI.

I got my 4 lug wheels from Beck long ago and they have about a 5" backset. On thes

e 5.5" wheels, compared to a 4.5", the additional inch is all to the inside.

With 175/70 tires I can fit the tip of my little finger between the tire and fender.

I think that kinda' proves my point @Michael McKelvey. I'm unsure what a "small amount" is, but the AC Enterprises wide 5s added track, and you needed custom offset wheels to make it work.

@Stan Galat, no, the face of the disk hub was exactly the same place as the face of a drum after they milled off maybe 1/16".

Even with drums, I would have needed the same wheels.

I re-centered my own wheels for the front of my old Spyder. I moved the centers out 3/8", which isn't much. But it was just enough increased backspacing to clear the fender lips. The new car has a 2" narrowed beam and aluminum Vintage190s, so no more problem.

It really shouldn't cost more to have special wheels done than swapping trailing arms. In fact, it should cost a lot less. The key is to find someone who can do the work(and do it properly!).

Get a set of 5" or 5.5" steel wheels and get the centers moved 1/2" or whatever you need for clearance. With 4.5" fronts and 5.5" rears on a Spyder, I can't rotate the tires anyway, plus they are different tire sizes. Uneven wear is NOT an issue.

@DannyP, I've always thought that the wheels would be the easier way as well. The trick, of course, is finding somebody willing to recenter the wheels. Commercial shops (around here, at least) aren't going to assume the liability. In theory, it ought to be easier than the trailing arms... but there seems to be more people narrowing trailing arms than recentering wheels. Most common folks aren't going to be able to do what you did.

@Michael McKelvey - thanks. That's good information on the AC Enterprises brakes. I've checked with Danny, and the AirKewld set also doesn't add track (although that kit is not "EMPI cheap"). 20 years ago, that wasn't the case. My 2003 JPS had EMPI 4-lug disc brakes on the back of an IRS narrow-body with 4-1/2" Mangles and 185/65s, which was John's preferred setup at the time. It was pretty much unworkable. In 2004 or 2005, CB came out with their "zero offset" wide-5 brakes (which have been discontinued, but which I have), which added 5/8" per side. Henry checked a lot of kits at the time (everything except for CSPs, I think), and at the time there just wasn't anything.

Anyhow, even with a true zero offset brake package, a guy wanting discs on an IRS pan would still need recentered wheels. I suspect the main point is that there is a brake package available, and that for a while at least, there were some wheels available as well. Does anybody know if the special offset 5-1/2" wheels Carey had are still available?

Used to be either Weldcraft or Stockton Wheel were the go-to places.

There's also Wheel Workz in Memphis.

The Weldcraft website says they widen wheels so it seems like they would change the offset too:

I don't know if the wheels are still available from Beck. At the time they were wheels they used on Spyders.

I live pretty close to Weldcraft.

I have a set of chrome Mangel 5 1/2" wheels that I have never used because I decided on the ones with the different offset. They are over 30 years old and last time I looked there was a little rust where the center joined the rim.

For an interested buyer, I might be persuaded to take them Weldcraft to get the offset changed.

The price might be something like $60 each plus actual Weldcraft cost plus actual shipping cost.

@Stan Galat posted:@DannyP, I've always thought that the wheels would be the easier way as well. The trick, of course, is finding somebody willing to recenter the wheels. Commercial shops (around here, at least) aren't going to assume the liability. In theory, it ought to be easier than the trailing arms... but there seems to be more people narrowing trailing arms than recentering wheels. Most common folks aren't going to be able to do what you did.

@Michael McKelvey - thanks. That's good information on the AC Enterprises brakes. I've checked with Danny, and the AirKewld set also doesn't add track (although that kit is not "EMPI cheap"). 20 years ago, that wasn't the case. My 2003 JPS had EMPI 4-lug disc brakes on the back of an IRS narrow-body with 4-1/2" Mangles and 185/65s, which was John's preferred setup at the time. It was pretty much unworkable. In 2004 or 2005, CB came out with their "zero offset" wide-5 brakes (which have been discontinued, but which I have), which added 5/8" per side. Henry checked a lot of kits at the time (everything except for CSPs, I think), and at the time there just wasn't anything.

Anyhow, even with a true zero offset brake package, a guy wanting discs on an IRS pan would still need recentered wheels. I suspect the main point is that there is a brake package available, and that for a while at least, there were some wheels available as well. Does anybody know if the special offset 5-1/2" wheels Carey had are still available?

IM does it all the time they have a sub contractor who specializes in wheels and they can refinish or widen and move the center to whatever you need. Question of asking and of course paying the cost of it. My original IM Aircooled has 8 inch mangels like chrome 4 bolt as standard issue on the back axle. I think they chose to do that then play with the trailing arms. Maybe they did not know Ron Lummus at the time. In any case, the rear brakes that IM uses vary from Empi, to VW Jetta Type IV I think is what I have and FYI, the brake pad is the same size as early 911 and it has a mechanical e-brake.

Now to the point of getting hub centric or 944 rear axles that would give you that there are issues there with spacing. I often think a Slice of Pie ala Bob, on a new build would be nice to give you more options.

@Michael McKelvey posted:The Weldcraft website says they widen wheels so it seems like they would change the offset too:

I don't know if the wheels are still available from Beck. At the time they were wheels they used on Spyders.

Beck usually (or used to) use a long swing axle on Spyders. This actually is closer to the original Spyders as all the original Spyders used the same size wheel and tire all around. They had a lot of backspacing for the 5.5" rears. Beck still use 4.5" in the front, less rubbing this way.

@LI-Rick posted:Here’s a guy on the samba that narrows irs arms.

https://www.thesamba.com/vw/cl...etail.php?id=1725100

Thanks for that, Rick.

I'm pretty sure those wheels are NLA from Carey.

@Michael McKelvey posted:I live pretty close to Weldcraft.

I have a set of chrome Mangel 5 1/2" wheels that I have never used because I decided on the ones with the different offset. They are over 30 years old and last time I looked there was a little rust where the center joined the rim.

For an interested buyer, I might be persuaded to take them Weldcraft to get the offset changed.

The price might be something like $60 each plus actual Weldcraft cost plus actual shipping cost.

Michael, that's really great of you to offer to do that. I'd be inclined to go that direction if it was my choice on a Speedster.

Even if Weldcraft charges $100 a pop, and $60 plus shipping for each wheel, and possibly powder coat to the color of your choice(about $100 a wheel), it's a bolt-on arrangement.

I'd take a $600 bolt-on versus re-arranging and welding the entire rear suspension.

I am a little concerned about the ability to powder coat over chrome.

I have emailed Weldcraft to get an idea of how much they might charge.

@DannyP posted:Used to be either Weldcraft or Stockton Wheel were the go-to places.

There's also Wheel Workz in Memphis.

Stockton Wheel made a set of 6”-8” wheels for me for my Manx. These weren’t modified, they were built from scratch. Stockton has their own centers and rolls their own rims. I don’t know how close to original VW design they are, but if authentic Mangel look is important to you, I would ask. FWIW, they’ll pretty much make anything you want.

Attachments

@Michael McKelvey posted:I am a little concerned about the ability to powder coat over chrome.

I have emailed Weldcraft to get an idea of how much they might charge.

AFAIK, you can’t weld chrome. (The off gas is extremely toxic.) Every piece I’ve ever had powder coated includes a blasting job as prep. Whether it would cost more to blast chrome or not, I don’t know. I’ve never done that. I do know that the bits for my Ducati I had chromed were prepped by blasting. Some (fenders) were previously painted, but the shift/brake levers and footpegs were chromed.

I got a cost from Weldcraft. They said it would be $150 per wheel with a 4 week turnaround time.

My first message to them mentioned chrome.