Wires. Switches. One at a time. Measure, cut, strip, fit the end, solder, connect, etc. etc. Little wires.

Ed, this is going to be one beautiful, special, and hopefully valuable car when you're finished. After all of the artistry that you've put in I wish that you could keep it (and give me a ride in it), but I understand the need to sell. I hope I get to see it before it moves on. Truly beautiful!

Accusump wired in and works with the switch. Fuel pump comes on with the key. Cut, strip, crimp, solder, heat-shrink....

Attachments

I've spend the last two days under a confined dash of a Berrien ( Meyers clone) dune buggy. It's hell to get into,... you roll over the side panel, then with the palms of your hands on the floor, tuck your knees against your gut and figure out how to roll a 180 onto your back....Only to discover the wire crimpers are still over on the bench... getting out from underneath there is a physical contortion event that tests your agility.

edsnova posted:...Cut, strip, crimp, solder, heat-shrink....

Satisfying work, though.

Nothing else in life has a more predictably positive outcome. (From reading this thread, apparently nothing else in the building of a Spyder does, either.)

First there are nine more connections to do, then five, then done.

I love the smell of rosin-core solder in the morning.

Love this part. Like Mitch says, it's steady, logical work with (usually) satisfying outcomes. It's looking good, Ed.

"Nothing else in life has a more predictably positive outcome. " then there is the negative connections to do :")

Ray, your fears are groundless.

Sacto Mitch posted:

Ray, your fears are groundless.

That's going low...

Ed, I know it's too late to say this now.

Wiring the dash is sooo much easier to do if you build a dash harness and make the connections on a terminal block installed in front of the drivers door. You get rid of 50' of useless 16 gauge wire serving instrument and warning lights. A 3 watt bulb does not require 16 gauge wire. The harness will be about the size of your index finger. I put it all in shrink wrap.

Horns work. I put the switches in for fitment check. The wiper switch wouldn't reach the top right hole so I disconnected the + wire and put it on my other switch (seat heaters, I think). I like the way it's looking. But.

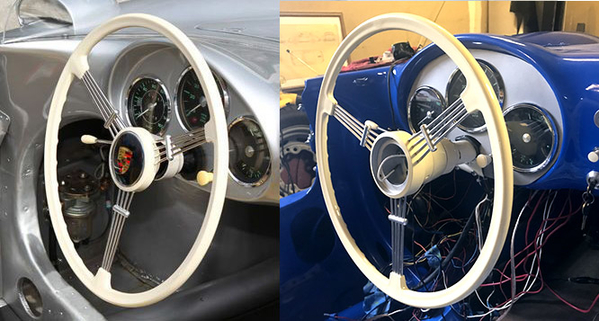

I think I've got to pull the steering column and rebuild it shorter. Here's a real one. Looks like the wheel is about 2-2.5 inches closer to the gauges than mine.

Weird. I measured all this like a year and a half ago, sat int he car with the wheel in my hand. Thought I had it pretty right.

But with the signal switch on it, the thing looks like it's farther out. I'm not sure how this has come to be.

Maybe it's an optical illusion. Anyone want to share with me their measurement from the back of the steering wheel to the binnacle eyebrow?

Attachments

From the back of my wheel to the eyebrow is 3.75".

I have a Nardi wheel that's 15.25" across, if that matters. Your wheel looks bigger.

I’m sure measurements would be more helpful, but here are some pics I snapped a month ago.

Attachments

Ed, I don't know Spyders, but making the wheels in the two photos the same size and comparing may make things a little clearer:

- The two photos are taken from different angles and with different lenses - the older car was shot with a longer (more telephoto) lens, so the perspective is compressed. Near things seem closer to more distant things than in the other photo.

- That said, it looks like the steering column in the original may emerge from the dash a little lower (or maybe farther from the tach) than in your car.

- It looks like the steering column in the original may be at a different angle from the horizontal, maybe angled a little higher, so if the two hubs were in exactly the same place, the top of the wheel in the original would end up closer to the dash

- The top of the eyebrow in the original may extend out from the dash a little farther than in your car.

- The 'collar' on the steering column in front of the wheel (whatever that's called) seems to be wider on your car than in the original.

- It's very possible, though, that I'm delusional. The older I get, the less I seem to understand about how many things work in this world.

Attachments

Ape man here: put it closer to the dash. It’s nice that it fits you, but it’s gotta fit a wider range of buyers than a subset of men under 5’6” who weigh less than 150 lbs.

Thanks, guys. My wheel is 5 inches from the top of the eyebrow. I could maybe tuck it in an inch if I pull the shaft and cut it and re-slot it for the coupler, then pull the column, cut off the mount and weld it back on an inch further up. Doing that would push the signal switch in an inch too, to about an inch and three quarters from the dash.

I was all set to get on with it just now when I reached down and pulled the light switch.

If I push that signal switch housing in an inch it'll be very tight to the light switch.

I do think when I tighten up the light switch it should straighten out and clear OK though.

That should leave the wheel about 4 inches off the dash, pretty close to where Carlos G's is.

I also figured out how this happened.

When I popped the wheel on a month or two ago and discovered the steering was a bit sloppy, I also noticed that the steering box was cocked forward a few degrees. The shaft from the box was not lining up perfectly to the steering shaft.

So I turned the box just a little on the beam so the shafts lined up, then tightened everything down. That probably pushed the steering wheel into the cockpit about an inch.

@Kevin - Bay Area I really like that A car. Had not seen that one before.

@Stan Galat I'm 5'7" and 155 don't make me come over there.

Attachments

Update:

3.75 inches, give or take a quarter inch, depending on how deep I drive in the coupler thing before clamping it down. Tomorrow I'll repaint the column and reassemble.

Attachments

Good job, Ed. I don’t think you would want it any closer than that.

That is a lot better both visually and for the driver. Nice work.

We'll get there yet.

Today I finished soldering/heat-shrinking the rear subharness.

It really sucks when something you do cascades like falling dominos into everything else, doesn't it?

Ed. we had to do the same thing to shorten the steering column. For a sec, I thought I was seeing my steering column on someone else's page.

Cleaned everything up, repainted, let it dry overnight and installed it this a.m. We're at 4 inches from the binnacle eyebrow and that seems fine.

I have a horn question now before I drive in the golden lady button.

Is there a clip or something that screws into the inside of the steering hub to act as a contact? There seems to be one copper/brass bit at the edge of the inside of the button, and I thought that should just touch the metal on the inside of the wheel hub and toot the horn, but when I tested last it wasn't good.

Maybe add a screw to one of the open holes inside the hub?

Assemblers, let me know. I don't want to be prying on that golden lady too much once it's done.

==

Addendum:

Holes near the edges of the hub...

Tab, tab, oooh, copper tab.

Attachments

A jumper ( ground) wire over the rag joint, this wire goes into the small slot at the base of the steering shaft and comes out the top center of the steering shaft it is secured with the center screw on your Lady button The other wire is connected to the tab on the base of the column the circuit remains open until you press the horn button .

Thanks, Alan. I have all that done. It works!

My question is focused on the button. That last contact from the bottom/inside of the button to the metal on the inside of the steering wheel hub.

Yes the metal rim on the button continues the ground circuit loop and is completed when you push the button.

Wiring updates. Got the brake lights working with the pedal the other day. Had to move the switch from the rear port to the front. Messy. But now the brakes light when the pedal is depressed.

Also: Headlights work...finally.

I'd originally wired them according to the build manual but that was a total no-go since I'm using a different turn signal switch and a floor-mounted dip switch. I messed about with them a couple days and finally set about rigging up a proper ganged two-relay setup I found in one of the big boxes of random electrical stuff I got from Alan.

That gave me bupkis too.

Then, this morning, I got the bright idea of tracing the wiring in that gang box and comparing it to...oh...every single headlight relay wiring diagram on the internet.

What I found was very interesting.

Turns out the guy who wired up that connector box was eight years old, and drunk. The relays were wired together as if they were mirrored, not parallel. No wonder Merklin tossed it in the box and forgot about it.

Rewired the gang box and—eureka!—there was light!

Spent part of tonight prettying that up, making the wires that go to the floor dipper, getting the stuff ready to connect to the wiring harness permanently, and pondering where and how to mount this in the car, along with the two relays for the seat heaters and maybe one more for the fuel pump (which is currently direct wired to key-on power through the fuse box with 14s...which I think is probably fine.

Attachments

I remember that bunch of relays came out of some Project number ___ ? :~)

Wait, you're still using an original Leatherman tool to, well, cut and bend stuff?

You're going to get scratches and wear marks all over it and 30 years from now, antique tool collectors won't give you a dime over $500 for it.

Put it back in the leather pouch, making sure not to scuff up the gold lettering, and buy some crappy, Taiwanese tools at Home Depot for your daily work.

Mitch, I picked that Leatherman up off the street in front of my house, just about 30 years ago now. Knocked on a bunch of the neighbors' doors trying to find its rightful owner and waited a week before dropping it in my Sears Craftsman tool box.

Been using it ever since (my only needle nose plier) and never had any idea it was particularly special. Chipped off the tip of the knife about 10 years ago so as a collector piece it's pretty much spent.

New relay bar ready to bolt (or rivet...?) in above the fuse box under the dash.

Two for the headlights, two for the seat heaters and one spare—maybe for the fuel pump?

Attachments

Ed, I had no idea about the Leatherman, either.

It just seems like the kind of nutball thing collector types would go gaga over. And sho 'nuff - a quick check with Mr. Google and here's one going for 100 bucks!

Of course, that includes the numbers matching leather pouch.

She run.

The good: I was able to get tach and (after some fettling) oil and gen lights. So the instruments are bueno.

The not bueno: Missing on #4. I'll figure that out later.

Now it's time to install the seat heater wiring, wrap and tuck up all those goddam wires, then get the shifter in, the gas tank bolted down, the clam hung, the rear wire harness and lights in, etc.

After that, sync the carbs, figure out why #4 isn't firing, etc.

Repeat: she run.

Congratulations, Ed. It’s been a long road and you’re not at the end yet, but you can see it from here.

Congrats !!!!!!

Geez Ed, sounds like a goldarned race car.

Congrats, Ed. It's really coming together!

The no. 4 not firing is most probably an idle adjustment or clogged idle jet. You will know once you getting it running again if 4 comes in when the throttle is opened and off the idle circuit. That is a very common issue with Weber carbs.

Good Job Ed....

Good job Ed. And you aren't kidding about having some wires to gather up and straighten out.