Update: I finished my improved sway bar brackets to move the bushings out to the ends of the beam where they rightly belong. Being me of course I made a complicated hash of these out of box stock instead of doing the efficient thing (like Danny) and just welding angle iron to the shock towers. I have no excuse.

Here is me at the beginning of the process. I mocked it up on a spare beam I had in the shop:

At this point the box stock looks reasonable. It's near the edge of the beam and can be affixed with muffler U bolts. Much easier than clamping it up and trying to weld directly to the car...or so I thought.

Ah but. In this position, the brackets would make it impossible to get a grease gun on the zerks, so I had to slice/grind a section out of the box to fit it closer up against the shock towers. Also, the U bolts are too short to account for the swaybar bushing carriers (and no one makes 2 1/8 inch J bolts, so they had to be extended.

No U bolt on the bottom beam tube—won't fit with the frame gusset I already welded in. So just a bolt welded in as a stud for the carrier. And a bit of angle to fit up against the stock beam gusset on the frame, bolted through. Why am I not just welding this in place? I don't know!

All test fitted. Center hole for the U bolt has reinforcement tubing to keep the cut box from deforming when the bushing carriers are tightened with "Chevy hands."

Studs are welded on the outside and the inside—same reason. Painted all the bare metal edges to discourage rust. In my defense: once these are installed all the ugliness of these cutaway edges will be invisible.

Studs are welded on the outside and the inside—same reason. Painted all the bare metal edges to discourage rust. In my defense: once these are installed all the ugliness of these cutaway edges will be invisible.

Still. This little interlude well illustrates why "building cars for money" will not—cannot—be my second act in my life's career. Chuck Beck I ain't. Not Carey Hines either.

Alan Merklin is a damn genius and I don't have enough years remaining on this planet to develop a tenth of his skills and ability.

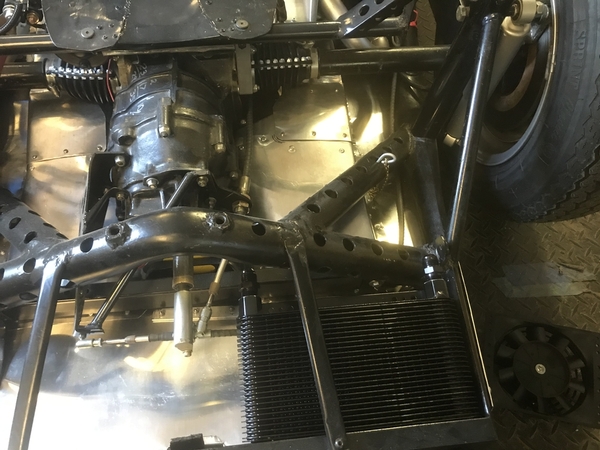

Meanwhile, my oil cooler bits came. I got Karen to help me take the back section off the car today and started test fitting that stuff.

That little fan is going under the cooler as a puller. I need to make a bracket for the front of the cooler body, and cut and fold the aluminum underpan into a ductworks so all the fanned air gets pulled through the plates.

I'll start on that tomorrow.