I installed a CB Perf. rotary (maybe a Carter? I dunno) way back in 1999 and it's still going strong. It has always made a weird growl-y whine when it starts up from day one, but it's still pumping - This will be the 12'th year!

@chines1 posted:I hate to be a Debbie Downer here, but I'll share this.

We haven't used the Carter fuel pump in many years, so things may have changed, BUT we had a 100% failure rate with Carter pumps within the first few years in service. This included a few private labeled carter pumps (CB brand internally regulated was carter at this time). Anyway, every single one of them eventually lost its ability to regulate pressure and defaults to roughly 9lbs. When this happens everything works OK at partial to full throttle, but at idle the cars drown and sitting still they flood completely and die... Not a big deal if you catch it early, but as you all probably know, a flood carb and a backfire can mean a call to the fire department and that ain't good....

Well, thanks for that background, Carey. I thought you were partial to the Holley pumps but didn't know why. First I'm hearing of this.

fwiw it's my intention to put the Malpassi filter/regulator back on the car, which I hope will keep the fuel pressure in spec even in the event of a pump default pressure failure.

@edsnova a regulator inline would be a good fail safe as the pumps never stopped pumping, just pumped too much. And maybe we just hit a bad year range for these pumps or something...

@DannyP 2003 to ???? probably 05/06 After replacing several dozen we just stopped using them outright and I probably replaced some on used cars that were still good but I didn't want to chance it. So... 100% failure rate is overstated, maybe 80-90%. But 90% of all statistics are made up anyway LMAO. That makes me think of Randy's favorite saying "15/16th of the world uses the metric system" I don't know why it made me think of that, probably lack of sleep. OK, back to work for me.

Great, now I have to go find what electric fuel pump I put on a few years back. ![]()

@Chris MacDonald posted:Great, now I have to go find what electric fuel pump I put on a few years back.

Chris just buy another one and put it in your emergency kit ![]()

Chris, don't worry about it. If the pump is a few years old, it's probably OK.

Welp...back apart.

Started out this am intending to do a 15 minute brake bleed to just perfect the pedal feel. After two hours (bleed. Try again. Try again with the front calipers off and clocked, Try again from the beginning) we found a drip below the T fitting on the rear firewall. That's the replacement fitting for the one that split at the seam after I installed it like two years ago. WTF?

The leak is very small: one drop after standing on the brakes. With the proportioning valve partly closed before there was no leak, but now that it's wide open, here we are.

We tried tightening all three and got no movement, but my assistant did manage to round off the flare nut from the main feed.

As I recall, I assembled this new one on the bench and the only flare I attached in situ was that main line from the proportioning valve. I may have put some red threadlock on these...

Of course, with the engine in it's hard as hell to get any kind of reasonable access to this part, so Vicegrips were employed.

No joy. So I pulled off the carbs to get some clearance to pull off the T and inspect.

Hopefully I'll be able to get it out tomorrow without damaging anything. And I'll put the CB vacuum reference plates under the carbs when they go back on.

I am a bit miffed though.

Attachments

This may sound redundant but when I initially bleed brakes, I place pieces of paper towel at all connections to confirm there isn't a slight leak.

.

I think the 20th century philosopher Santayana put it best when he said, "If it's not one thing, it's another."

No wait, sorry, it was Roseannadanna. I always get the two mixed up.

.

I feel your pain..... It took me a year to sort out my "turnkey" first Spyder..... Time to put in the Antifreeze mentioned in another topic and come back tomorrow when its had time to do its stuff..... You'll get there![]()

Attachments

@Gordon Nichols posted:

I'd add the tag-line, "so use good hardware".

@edsnova - really sorry, man. Hang in there.

So I got in there this am and put the wheels back on the front, then lifted up the rear a few inches to put the end of the main brake line above the height of the fluid reservoir. Put garbage bags on my seats in case I'd have to pull out lines in there between them, and then managed to extract the troublesome manifold and its attendant brake lines.

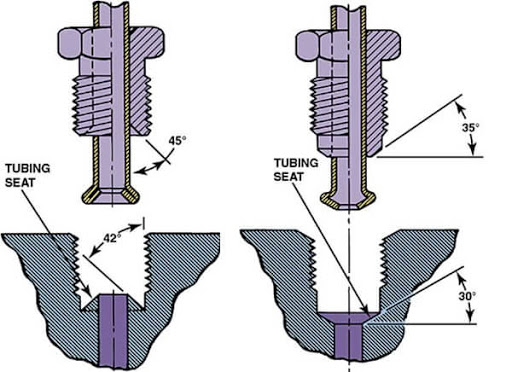

I could see that the T junction was not split again, so in reconsidering those steel braided lines—which came in bags with the rest of the parts I bought with the kit, I compared the male end of one with the bubble flared fitting that's supposed to go in there. Interesting:

It was these fittings which had given trouble before. So much so I gave them each a wrap of teflon tape before screwing them in last time.

In consultation with Cory Drake I learned that fitment issues with these are very common, if not universal. He suggested I replace them with "stock" hoses and, digging through my box of brake lines I did come up with something a bit less flashy:

About three inches shorter than the steel braided lines, but by then I had already decided to put a short length of hard line into the T junction to give it something it likes, and I had a spare male/male barrel fitting in stock.

Comparing the business end of the "rubber" line to the braided line we see maybe what the problem has been:

I'm thinking that the beveled edge, in steel, is different enough from what is supposed to fit in there as to account for my troubles.* Fingers crossed on that.

So I reassembled the whole mess on the bench and then popped it in the car.

Went out to buy a power bleeder but it's Easter, ya know, so I just pumped the brake pedal a little with a mop while I opened and closed the bleeders. Seems like maybe it will work. I'll get an assistant back in here tomorrow or Tuesday and—I hope—finally get the brakes squared away.

=

*Hat tip to Gordon as well on this.

Attachments

Interesting. Where did those braided lines come from?

Mine came from Airkewld in Arizona. But since they are designed to fit a Beetle, the rears were nowhere near long enough. The ones I got were AN-3 on both ends. Metric adapters to the hard lines in the chassis and a banjo adapter at the caliper. I bought the longer hoses from Pegasus racing.

Believe it or not, I had absolutely no trouble with any leaks of any kind.

Hope you get it sorted, Ed.

Like I said, D: They were in a bag which was in a box with the other brake parts I got with the build. Cory says the first set he got for the Hoopty (EMPI or CB) did something similar and he ended up going back to stock lines. Sartwell told him they were bad all over the hobby at the time.

I of course knew nothing of this. The threads are regular VW metric (M10-1?) and that's what fooled me.

Cory surmised that some Chinese manufacturer made them wrong and a salesman on commission pawned them off on EMPI's (or someone's) buyer anyway. This would have been mid 2000s. Pretty sure that's when most of the parts I got were stockpiled for this build.

Update: Pumped the brakes, bled them, the air came out, the pedal came up, and then...

We broke them. Pedal sank to the floor. Spongy, comes up a little when pumped but not where it was. I think we blew a seal in the MC.

So that's pretty great.

No leaks up front. A tiny drip still from the damned T junction.

Plan is to again R&R the rear system—all new lines and fittings—and see about changing out the MC as well. Because that little drip ain't what did this.

Knowledgable advice welcomed.

I'm glad it broke under test conditions, Ed. You'll feel much better once it's out and you've got your new parts going in. Good luck.

.

Have you been monitoring fluid level at the MC reservoir?

Did it just drop?

.

@edsnova posted:

I'm not sure exactly what I'm looking at, but it appears that those are two dissimilar fittings. Like one of each of these?

FWIW, my long time buddy and pro Ducati mechanic once warned me that Teflon tape was for plumbing and if he ever found any on my bike again, he'd never work on my bike again. (After he'd dug a microscopic piece of Teflon tape out of one of my carbs after trying for two hours to get them sync'ed.)

Brake line fittings seal at the flange, if you're using tape to get them to seal, you're just putting a bandaid on a leaking flare (which will most likely always allow air into your lines.)

Attachments

Yeah, and since the brass T had the wrong fitting in it, it's seat is trashed now and needs to be replaced.

Ed can't seem to catch a brake these days. ![]()

@Sacto Mitch posted:.

Have you been monitoring fluid level at the MC reservoir?

Did it just drop?

.

it dropped in proportion to how much I was bleeding out, and I refilled it as needed.

Bob: IM S6 will be appearing all week in the Speedster Lounge high atop the first floor of the lovely Fixxit Resort Hotel and Carwash. Shows at 3:00 am and 5:45 am. No cover, 11 drink mimimum, try the pheasant! Drawing for a free Spyder Bimini top at each show.

That's show business, folks... ![]()

Good one, PB. Those with removable bikini tops get free admission.

Late update. Neighbor lent me his vacuum bleeder and my brakes are operable. Took the car to a little show in Glen Burnie last Saturday and met up with Cory and Chris.

What was the problem, you ask? It was not just the T junction in back! Nor the couplers. It was also the brake light sender switch in front. Bleeding through the spade connectors. So I chucked that one and plugged the port, and moved the wires to the other switch.

So the brakes work. But I'm also waiting for flex lines with banjo fittings, as my hard lines, where they go into the calipers, hit the bodywork on hard bumps. They'll be OK for now like this but as soon as the new parts come in I'll be re-making the rear brake lines a third time.

Oil also seeping from the axle boots. I got those big accordion style ones not realizing I could also get a split boot shaped more like the stock item. So I ordered a set of those, supposedly German made.

Tried aiming the headlights last night. I think they might be OK.

Today I made a set of rear axle limiting straps similar to the one's @DannyP made for his car.

With these, downward axle travel is limited to about 2 1/2 inches from the neutral ride height, meaning the suspension cannot "jack." Maybe not needed for the way I'm driving it but worth trying out to see if they harm the ride quality. They can be put on or taken off in about 10 minutes with a couple 3/4-inch wrenches.

I do still like this car.

Attachments

Lots and lots of little details to see in every photo - Those little things that make you say, "Wow, that's really nice" when you see them. And you keep seeing more every time you look.

Nice job, Mr. Ericson

Second that motion ![]() ... it will be hard the day you sell that baby. Looks so awesome.

... it will be hard the day you sell that baby. Looks so awesome.

Each time i look at the photos I see more cool stuff !

Ed-That’s the same thing that happened to my switch when I bottomed out over a set of railroad tracks and thumped my MC.

Only it was leaking everywhere. The spade lugs like yours as well as where the metal sides were crimped over the phenolic and the threads, too.

"I do still like this car."

As well you should.

Cory, Kelly and I all jammed into the Annapolis C&C at The City Dock. Couldn't park near each other but we managed to make contact.

I got there first (an hour drive!) (And I got lost and had to ask the Navy dudes guarding the base where the hell I was going!) circa 8:20. Parked it and got swamped.

Kelly rolled in next with his maroon beauty. His car is running well, as is mine.

Cory did his usual get-off-work-come-to-show thing, I think. He got a spot next to the water and ended up chatting with a bunch of Mustang fellas he's interacted with in the past. Hoopty is also looking good these days.

Gorgeous setting, this is. Yacht club with public rest rooms. There was a fairly good sized contingent of young kids running significant stereos as well.

Basically everyone who gets a new Vette brings...

I bugged out after about an hour to make brunch for Karen. Also hit the FedEx copy store and Office Depot for some Carlisle accoutrements. Driving the Spyder in normal afternoon city traffic is still fun...but not as fun as other situations. Anyway, a bunch of stops, a bunch of hot starts, and no mishaps or trouble of any kind. Cleaned these bugs off the car when I got home and set about making our name tags.

Attachments

It's a light for nighttime racing use.

@DannyP posted:It's a light for nighttime racing use.

oh, now I'm seeing them on the side also...

wow, all the details that can be done on these cars

I thought it was where you inserted the rolled up $100 bills 🙂

No those are the "wallet lightening holes." Lots of them on every Spyder.

@edsnova posted:No those are the "wallet lightening holes." Lots of them on every Spyder.

Those accept stacks of $100 bills

OK guys! 2 days 'til Carlisle and I went ahead and rebuilt the rear brake lines using some soft lines with banjo fittings that shipped from Latvia. The hard lines to the rear calipers had to come up and over and make a sharp bend down into the ports, and I found that the apex of that bend hit the inner fenders on strong bumps.

The car was stopping fine but for how long? The banjo fittings make for a lower profile connection at the top of the caliper and now the high point is a bolt head. Plus it's now a flex line that goes to a hard line running along the frame rail to a bend where it goes to the T fitting, instead of a hard line from the caliper running along the spring plate to a soft line bending to another hard line to the T fitting.

No leaks and she stops OK.

This morning I strapped the hard lines in neat and then got after the sump plate.

It's been dripping a while now (no, not that bad!) because one of the studs was short and the acorn nut on it was missing the copper washer and only had like 2 threads. I figured while I was in there...

So I got a new gasket and stud/nut/copper washer kit. When I checked the stud it was just turned in too far, not pulled out or stripped as I'd feared. All the rest were solid so I left those and went with the new nuts and one new stud.

Decided while the plate was out I'd put in a drain plug, as the other one I put in the sump is less than perfectly accessible with the underpan on the car (you can see it in the lower left).

So I got a quarter inch NPT drain plug and the requisite tapered 18 thread tap. The plate was already center-punched on the thicker boss, so it wasn't too tough. Three quarts of Brad Penn and we're back to just above the "add" line, which seems to be the sweet spot with this engine.

I'll run it tomorrow and throw it back up on the lift before stepping off for the hotel. May have to once again sideline my Filter King as well. Hope it's all good.