@ALB types faster than me!! but here it is anyway.

The long transmission "what's going on in that box?" explanation (from kindergarten to college in 9 paragraphs):

There are multiple ratios in a transmission and they are expressed differently. There is the gear ratio of each gear and the final drive ratio. It helps to think of it in steps; power goes from the engine into the transmission, out of the transmission into the final drive, and out of the final drive to the wheels. To wit:

The transmission has an input shaft that spins at whatever speed the engine is turning. That rotation goes through the ratio of the gear selected and that turns the output shaft of the transmission at a different speed based on the ratio. That speed of the transmission output shaft then goes to the final drive and goes through the final drive ratio (the ring and pinion gears) and spins the axles/tires at the road speed of the car. If we know the circumference of the tire, we can multiply the axle rotation speed by the circumference and get the road speed for a given engine speed. Our transaxles combine the transmission and the final drive into one unit, which makes it seem confusing, but it all works the same as if we had a transmission, a drive shaft and a rear end like a pick-up truck.

Let's make up a super simple imaginary transmission to illustrate. Let's make it a 2 speed transmission to keep it simple. First gear ratio is 2:1 and top gear ratio is 1:1(say 2 to 1 and 1 to 1 out loud). If the engine is spinning at 1,000 RPM the transmission input shaft is also spinning at 1,000 RPM. After going through 1st gear the out put shaft is spinning 500 RPM. In top gear at the same engine rpm the input shaft is spinning 1,000 RPM and the output shaft is spinning 1,000 RPM. If we were buying this gear stack from a catalog the gears would be sold as a 2. first gear and as a 1. top gear. The second half of 2 to 1 or 1 to 1 is implied as only the first number is given. We hear .82 used frequently for a type 1 transmission 4th gear. It means .82:1 (point 82 to 1) or that the output shaft spins .82 times slower than the input shaft. This is called an overdrive gear.

Now let's add a final drive. Let's make that final drive ratio 4:1. That means the axles will spin a 1/4 the speed of the output shaft from the transmission. So all together if the engine is spinning 1,000 RPM and we select first gear, the output from the transmission spins at 500 RPM and the tires will spin at 125 RPM. In top gear with the same engine speed our axles will spin 250 RPM. If we bought this final drive from a catalog it would be sold as a 4 (with the to 1 implied as with the gears). We hear folks say "I have a 3.88 ring and pinion" and that means a final drive ratio of 3.88, or 3.88:1 (3.88 to 1).

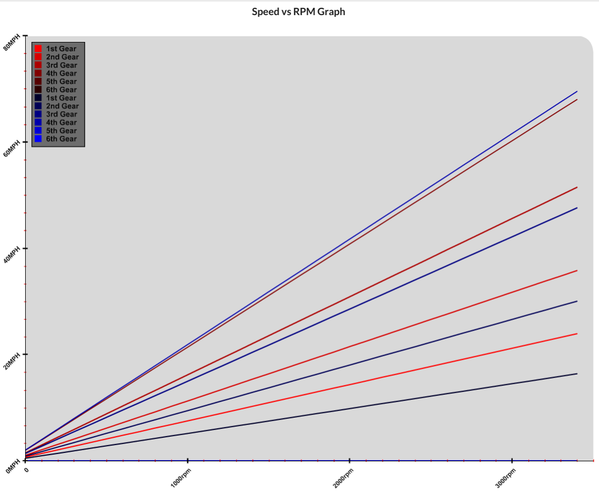

So that's the simple explanation of what's happening to the engine RPM getting to the RPM of the tires. Once we've got our heads around that, we can start to talk about torque multiplication. We know that in first gear of our transmission the engine spins 8 times faster than the tires and so it has an easier time moving the car. We can think of gears like being levers and the lower the gear (1st in our transmission) the longer the lever. It's multiplying the torque of the engine at the tires. This is where designing a transmission gets interesting and difficult. As we move through the gears the engine drops RPM at each up-shift. If we go back to thinking of levers and we're moving a big rock, we don't want to suddenly switch to a lever that's too short so the rock stops moving. That what having too big a drop in RPM at a shift feels like. Getting this right is what makes a transmission feel right...or wrong. I'm guessing your transmission this is the feeling you're getting particularly between 3rd and 4th, but maybe 2nd and 3rd, also.

Now to get what we want we need to know several things; 1) Tire size 2) Engine max torque RPM or torque curve 3) Number of speeds 4) Intended use. There is no use in our cheating on any of these if we want to make ourselves happy. A car designed to make the most of a curvy road with max speeds of 80 MPH will make us very unhappy if we spend 75% of our time on the highway.

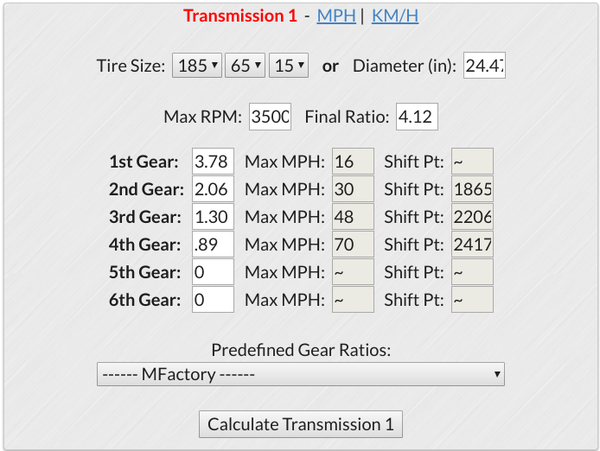

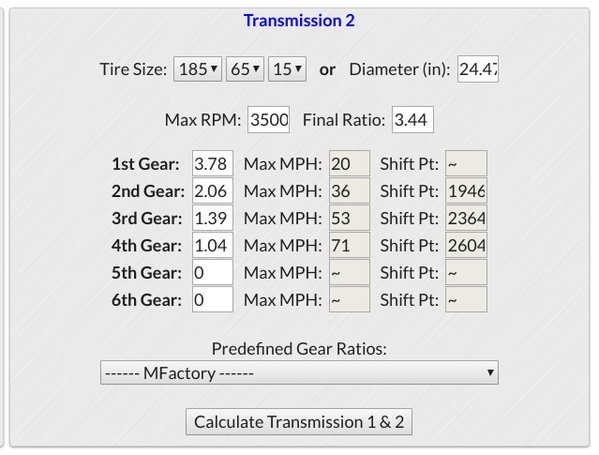

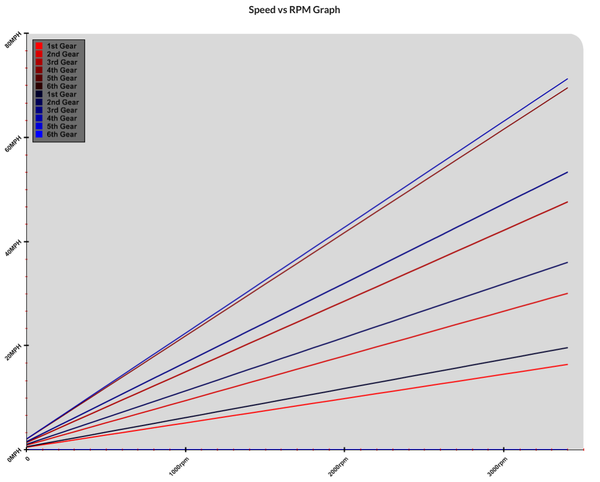

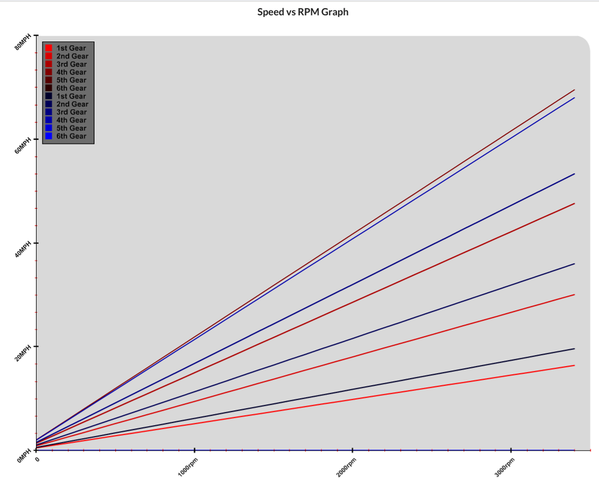

Once we know these things we need design tools. We need a gear calculator like this Weddle Gear Calculator. We need to know our tire size for that so we need a tire size chart to find circumferences and heights to enter into our calculator. We also need to know what gearing is available, so a catalog like the Weddle site is handy, too.

I referenced Stan's transmission above ( @Stan Galat you got a link? I can't find it) and we see it's a 4 speed designed for the engine characteristics and his intended use. His conversation around it is very useful to illustrate the thought process at play. My transmission is very similar with tweaks for the different characteristics of my engine and not surprisingly it's really close to being the same. We are always limited by what is available, and the budget, and what we want. But this is the 101 on getting there. Probing the brain trust here is a huge part of getting there, too. There's a ton more to explore like drivetrain losses, and other stuff, but in our case it's not really necessary to go there to get something good.

There...I think we only got as far as 12th grade, but it's far enough I think. Oh, I almost forgot, @MotoCarlo your final drive would be written 4.12:1 or sold as a 4.12 ring and pinion. That should work pretty well for back roads. I think what you might be after is a close ratio gear set dropping 3rd and 4th gear down and closer together, and keep that 4.12 if you're not doing much cruising at 70+.