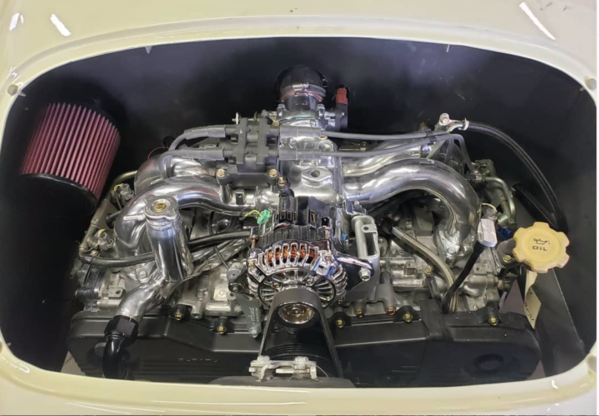

Went down to VMC on Friday to get some measurements and ideas for the Spyder. While there Greg showed me an outlaw speedster with a Subaru Engine and transaxle in it. He raised the engine a little more to get the shorter oil pan even higher for safety. This is not a mid engine installation so the space behind the front seats is still intact. What was really cool is how the clutch cable and Bowden tube are moved and re-secured. Also the shifter and linkage work perfect. Since a little of the sheet metal had to be trimmed due to the new overall height of the engine and trans, a new cover for that area had to be fabricated. It looks similar to a little saddle but is centered so it divides the seating area back there into two little mini seats ! Quite clever and will look nice and finished.....Photo's below............Bruce

Replies sorted oldest to newest

That rear seat is going to look really cool! It reminds me of the rear seats in an early 911.

Great fabrication! Neat clean and looks like it belongs!

This. Is. Excellent.

Bruce, any pictures yet of the Spyder IRS chassis?

Li-rick, nope, not yet. Greg just got the last Spyder off the welding jig before mine. Possibly next week he will start on the frame. First thing will be a visit from Kevin Zagar, Mendeola Suspension, to confer with Greg on how best to build in his suspension and still get a radiator in up there as well.

By the way, the radiator in the Subaru Speedster looked really good in as much as how it was installed up front. Greg uses AN hose and fittings for all the coolant hoses so this means that the coolant stand off tank/manifold on the engine will need to be removed and weld on an AN fitting in lieu of the std. hose connection. The photo below is of my engine and that tank/manifold. This little vertical tank was added by John over at Outfront and solves the air entrapment issues since it is the highest point on the system. looks good too ! Most likely the intake manifold will need to be removed for access.............Bruce

Attachments

Speechless. . . .Your collaboration with Greg is like listening to two virtuosos on the same stage bring out the best in each other! Stunning!

Please keep the pics and updates coming! Absolutely cant wait to see it all come together!!

I took some pictures of that Subaru wide body when I visited the @VSpyder shop in April. I really liked the way Greg had laid out the cooling system. Some real thought and quality components went into the execution. Seeing it firsthand cemented my thoughts that if I couldn't do it myself, then Greg should do it.

Attachments

This is VERY cool and we are fortunate to have a reputable Speedster builder who has the experience of working with the Subaru engine and is now applying it to a pan based Speedster. AWESOME!!!

JMM (Michael) posted:I took some pictures of that Subaru wide body when I visited the @VSpyder shop in April. I really liked the way Greg had laid out the cooling system. Some real thought and quality components went into the execution. Seeing it firsthand cemented my thoughts that if I couldn't do it myself, then Greg should do it.

Could you explain how he laid out the cooling system, please ? How did he route the hoses from front to back especially where he had to get through the front beam ? Just curious if it was a similar system to what I did. Thanks.

I don't know David, I looked at the radiator from underneath just as they were lowering it to move it so I didn't have time to study it. I know that the radiator is a Two Pass unit, ie, the coolant goes thru half the radiator then turns around and goes thru the other half. The top and bottom tanks have sealed baffles inside to direct the coolant this way. The core is a I" tube, two row aluminum unit with welded tanks and giant AN connections. The square inch area, size and construction of it is about the same as I used to cool a Jeep V-6.................Bruce

Sure thing, @David Stroud IM Roadster D. The install was in process when I saw it, and Greg was quite busy when I was there, so I didn't bug him much with questions because most of it was pretty obvious. Anyway, here's what impressed me. First the materials chosen:

-AN fittings instead of hose barbs and clamps allowing smooth but tight 90 degree bends with no restrictions, and one assumes no leaks if installed properly. Ask @Jim Kelly about restrictions and ask @Stan Galat about leaks (...or anything to do with pipes, he probably knows more than the rest of us put together about the subject).

-All aluminum radiator, possibly double pass and definitely big enough, no plastic end tanks. The radiator was installed with the top higher than the bottom (with the outlet on the high side I think). The high part of the rad looked to be much lower than the swirl pot at the engine.

-He had John at Outfront Motorsports (engine builder) put a welded on aluminum swirl-pot/coolant fill tank on the coolant outlet of the engine, that in turn has an AN fitting welded on. This swirl pot is the highest point in the system.

-The hoses weren't installed when I was there, but it looked like they would be able to run through the tunnel and in the picture I just snitched off Greg's instagram feed it looks like the return line is coming from that area. I'll attach the photo. We'd need info from greg on this, but whatever he did, I'm confident it's up to snuff.

Lastly, The whole thing looked factory. Clean, sensible. It looked like a COMPLETE SYSTEM, not an assortment of parts and a few coins thrown in a fountain in the hopes it would do the job. Here's that instagram pic (also, look at that rorty exhaust!)

Attachments

JMM (Michael) posted-He had John at Outfront Motorsports (engine builder) put a welded on aluminum swirl-pot/coolant fill tank on the coolant outlet of the engine, that in turn has an AN fitting welded on. This swirl pot is the highest point in the system.

What is a swirl-pot?

This whole thing (as well as the ride in Phil's Spyder) is making me rethink my great love-affair with the Type 1.

A Subaru 5-speed, not more rare that shards of the true cross (like a Berg-5) and a legit 200 hp engine for considerably less dinero than the attendant air-cooled stuff sounds really, really good right about now... as my own car sits on jack-stands, waiting for parts from Italy and GB to make their way back to my garage.

@Stan Galat - I was wondering the same. Considering the expense, do you think it better to use the Subaru 5 speed with a Subaru engine, or the Berg? With the Berg, you don't have to buy a reverse ring and pinion or new axles, and possibly suspension parts, but with the Subaru, you don't have to buy the adapter.

Todd...I think he's talking about this (see photo).

Another thing will be the exhaust routing. Hopefully equal length. Greg said that with it being a mid-engine and IRS, it may be necessary to route it up-over the trans and down again. With a Spyder there's a lot more room to work with back there. That remains to be worked out though. Besides himself, he has some pretty swift craftsman in his employ......Bruce

Attachments

JMM (Michael) posted:

Thanks. That makes perfect sense. I did not even know that was the coolant output from the engine. I assumed is was the intake because it is on top and the other port is on the bottom.

Stan Galat posted:This whole thing (as well as the ride in Phil's Spyder) is making me rethink my great love-affair with the Type 1.

A Subaru 5-speed, not more rare that shards of the true cross (like a Berg-5) and a legit 200 hp engine for considerably less dinero than the attendant air-cooled stuff sounds really, really good right about now... as my own car sits on jack-stands, waiting for parts from Italy and GB to make their way back to my garage.

Heresy! The weather or Jeanie being in Colorado......or something....is rattling your brain. go sleep in your VW panel bus for the night and call me in the morning if this persists and I'll talk you down.

Either way it flows it should work the same. Subarus are a little weird with the coolant system, like the thermostat is on the return line. Strange, but a couple hundred thousand Subies on the road and it all seems to work. Speaking of plumbing, I need to get myself back out in the garden and get back to work on that irrigation system my wife wants done before next weekend.

Stan Galat posted:This whole thing (as well as the ride in Phil's Spyder) is making me rethink my great love-affair with the Type 1.

A Subaru 5-speed, not more rare that shards of the true cross (like a Berg-5) and a legit 200 hp engine for considerably less dinero than the attendant air-cooled stuff sounds really, really good right about now... as my own car sits on jack-stands, waiting for parts from Italy and GB to make their way back to my garage.

It is another learning curve for sure but I am happy with the subie torque, the no carb and my creature comforts like the recaro seats. I can drive 10 hours and I never have any body issues upper or lower ![]()

JMM (Michael) posted:

Thanks for the info, Michael. This setup looks to be like the one Beck does and works well. Near horizontal rad up front similar to what I did. I don't think what you say is a swirl pot is actually that. I believe what you have there is simply a rad cap on the top of the highest point in the system. We used swirl pots on Subaru engines in airplanes and a swirl pot ( by definition ) Is a canister which has one inlet and two outlets on it.

The main inlet and main outlet are hose fittings attached onto the pot on a tangent in different directions and coolant from a high spot on the coolant system would enter the swirl pot near the center and swirl in a circle and allow any air in the system to rise out a top vent while the coolant (that had been swirled) would exit the can at the bottom back into the cooling system . Google swirl pot and you may see examples.

The Subaru engine has been proven to be a very viable alternative and is within the capabilities of a " mechanical handyman " to do at home. If I did another....and I might, I again would dumb mine down with a Megajolt Ford edis ignition and a simple Weber 32/36 carb. Not a system that all would go for but that's just the way I roll. Dead simple is good for me.

The conundrum that I feel I'm in is that I have a perfectly running 2332 built by a well known builder so why pull that out and go for a Soob ? On the other hand I could probably sell my good running 2332 and get enough money to pay for 1/2 or better of the Soob conversion cost and I already know how to do it. I don't have much $$$ invested in my Speedster / Roadster experience either so a Soob could be very easily justified.

Interesting to hear Stan think about it....

JMM (Michael) posted:Either way it flows it should work the same. Subarus are a little weird with the coolant system, like the thermostat is on the return line. Strange, but a couple hundred thousand Subies on the road and it all seems to work.

If you don't want a stat on the return line and need things a bit more German, a BMW stand alone stat could be easily adapted onto the outgoing line. There wouldn't be any advantage though.

One thing to note is that Beck also has a coolant overflow tank, as well, in the front of the car.

I had my coolant overflow in the back with the engine and I just put in a second tank that looks very much like what you have on the BECK except it is not under pressure but is plumbed from the overflow tank directly and correct the overflow and then allows the engine to suck it back into the coolant system. So far the results are very positive and my engine coolant has not gone down and I have not gotten any air bubble issue or need to bleed the coolant system. This season will be the big test.

David I agree with you it is a conundrum but if you could find a buyer and arrange to do it near seasons end you would have the whole winter to do it... and that means 6 months... ![]()

Todd M posted:@Stan Galat - I was wondering the same. Considering the expense, do you think it better to use the Subaru 5 speed with a Subaru engine, or the Berg? With the Berg, you don't have to buy a reverse ring and pinion or new axles, and possibly suspension parts, but with the Subaru, you don't have to buy the adapter.

Well look at the options, if you use the stock ECU, the tranny plugs right in and sends all the info of the VSS, to the ECU, you can also have Drive by wire so it really makes the whole car function with a 2006 ish ECU. You can even get cruise control by using the stock ECU which already has the program in it by simply adding the clutch, brake and momentary switches necessary to operate the unit.

The Subie tranny with the reverse Ring and Pinion is now pretty mature.

I know I was the guinea pig... wew still alive. ![]()

Berg is fine on a VW platform but what is there not to like in a full platform change that was made to work together? I think we need to not reinvent the wheel when a million cars are out there ... WORKING.

BTW, I wish I would have asked @550 Phil, to get a ride in his really nice Spyder it was so nice and I heard so fast.

It would have been nice to compare a cammed 2.5L with Stinger ECU ... maybe next year.

next you people will be considering electric. I am crushed.

You know, when I think about it, having the thermostat on the return side isn't a big issue. Today I recalled that GM used a double set of them on the return on their Toro Flow V-6 478 CID Diesels way back in the 60s. Never had any problems with that part but did on just about everything else on them. It eliminated the bypass hose as well. Also Detroit diesels in locomotives had the thermostats on the return too . Funny how you remember stuff like that a hundred years later ! Probably because it was outside of the usual parameters....Bruce

You're right, David, it's not a real swirl-pot. It kinda acts like one during the burping I imagine, by running the car with the cap off until all the air is out, then toping off to whatever level is right.

The thermostat on the inlet isn't a big deal really, just a tad unusual. The circuit is...well... a circuit. Stop the flow from circulating anywhere you want and there's no circulation. Is this is circular reasoning? ![]()

I decided on Subie power because I can travel from 100' above sea level to 7,000' in about an hour and a half. I plan to travel up into and over the mountains a lot, so fuel injection for me. Plans are for heat and air conditioning, why have a coupe if it's not a year round driver. Plus, I've done all sorts of air-cooled stuff in the past and I feel like I'm ready to do something else. Like Stan said in his comments about electric, every situation has a solution that works better.

Irrigation system 90% complete. Yay. My back hurts.

Well is you had another car it would be my Beck hurts

I thought I read somewhere a while back that Greg at VMC was working on a tubular chassis. Maybe I'm mistaken.

I think Greg is working pretty hard right now just keeping up with demand.

I'll bet he is. Good to see his business is doing well.

JMM (Michael) posted:Sure thing, @David Stroud IM Roadster D. The install was in process when I saw it, and Greg was quite busy when I was there, so I didn't bug him much with questions because most of it was pretty obvious. Anyway, here's what impressed me. First the materials chosen:

-AN fittings instead of hose barbs and clamps allowing smooth but tight 90 degree bends with no restrictions, and one assumes no leaks if installed properly. Ask @Jim Kelly about restrictions and ask @Stan Galat about leaks (...or anything to do with pipes, he probably knows more than the rest of us put together about the subject).

-All aluminum radiator, possibly double pass and definitely big enough, no plastic end tanks. The radiator was installed with the top higher than the bottom (with the outlet on the high side I think). The high part of the rad looked to be much lower than the swirl pot at the engine.

-He had John at Outfront Motorsports (engine builder) put a welded on aluminum swirl-pot/coolant fill tank on the coolant outlet of the engine, that in turn has an AN fitting welded on. This swirl pot is the highest point in the system.

-The hoses weren't installed when I was there, but it looked like they would be able to run through the tunnel and in the picture I just snitched off Greg's instagram feed it looks like the return line is coming from that area. I'll attach the photo. We'd need info from greg on this, but whatever he did, I'm confident it's up to snuff.

Lastly, The whole thing looked factory. Clean, sensible. It looked like a COMPLETE SYSTEM, not an assortment of parts and a few coins thrown in a fountain in the hopes it would do the job. Here's that instagram pic (also, look at that rorty exhaust!)

Are they stock? Or custom? Exhaust. How does it sound? What muffler is use? What Subie motor?

thanks

aircooled posted:Went down to VMC on Friday to get some measurements and ideas for the Spyder. While there Greg showed me an outlaw speedster with a Subaru Engine and transaxle in it. He raised the engine a little more to get the shorter oil pan even higher for safety. This is not a mid engine installation so the space behind the front seats is still intact. What was really cool is how the clutch cable and Bowden tube are moved and re-secured. Also the shifter and linkage work perfect. Since a little of the sheet metal had to be trimmed due to the new overall height of the engine and trans, a new cover for that area had to be fabricated. It looks similar to a little saddle but is centered so it divides the seating area back there into two little mini seats ! Quite clever and will look nice and finished.....Photo's below............Bruce

How much higher did he raise the engine and tranny Bruce?

The angle of the axels are a bit different than mine but I think they are much like a beetle Subie install. So good stuff.

Guys that have an Audi watercooled had a lot of CV boot issues using a Type I tranny but If you do a full subie you can get the axels completely straight and even eliminate the CV boot issue that some people get.

If you stay to within VW beetle angles there are no issues in the first place.

Hence the reason for the short oil pan from Smallcars.

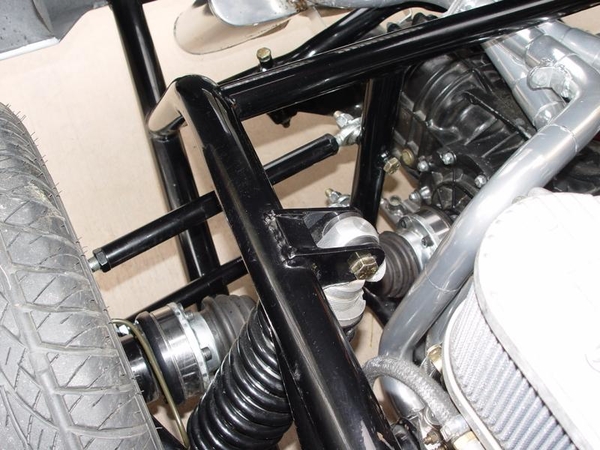

In a Spyder, if you are going Subaru, the BEST option is a Subaru 5 speed, but that also means fabricating a custom rear suspension as ALL Spyders have either swing-axle VW or DeDion tube.

With the Subaru engine exhaust ports on the bottom, it would be easier to route the exhaust to avoid the suspension, unlike with a type1 VW.

Ray, Phil's car is a BLAST! Honest 200hp and 8k redline. If I had to do it again I'd go Suby/5speed/custom IRS front and rear with custom anti-sway bars. Deeper fenders for wider tires too.

In a Speedster, I think I'd opt for the reverse ring and pinion, and keep the Suby trans and motor. Clutch slave on the bellhousing makes it a no-brainer.

Well if I could sit in that rocket ship, ![]() and I can't in reality at all, it might be worth doing a 914 ish flared fender routine on that spyder to keep it planted to the ground. That would be fun for sure.

and I can't in reality at all, it might be worth doing a 914 ish flared fender routine on that spyder to keep it planted to the ground. That would be fun for sure.

DannyP posted:In a Spyder, if you are going Subaru, the BEST option is a Subaru 5 speed, but that also means fabricating a custom rear suspension as ALL Spyders have either swing-axle VW or DeDion tube.

Well, apparently not ALL, but point taken.

This was supposedly built by Vintage around 2004. Why wasn't this pursued further? Was there an issue with the handling? Too expensive?

Attachments

Rick, I'm aware of these, but there were only a few, and Greg didn't want to build me one in 2016, when I ordered and received my painted body on frame, almost a roller. So maybe I'm wrong, but it doesn't appear to be a current option.

I believe the origin was way back in the ACI days, before Greg got all the tooling and molds from them and started Vintage Spyders.

Ray, I'm really not a fan of flared Spyders(or Speedsters) except for Angela's black one. That was/is badass!