Am I totally in orbit with all this or am I simply missing an underlying concept or assumption that is causing my brain to catch fire?

First of all Joel, I can't tell you how much I like you and what you are bringing to the discussion.

I was where you are about 10 years ago - wondering why the hobby seemed frozen in amber, and not picking all the low-hanging fruit that other branches of the ICE tree have been harvesting for years.

After many engines and many experiments, I can tell you this: there are really, really smart people doing all sorts of things with the T1 VW engine - and if (almost) none of them are doing something, there's generally a reason.

To start with, yes - there are guys doing roller rockers in T1 engines. Keeping the lifters parallel is an issue, which can be overcome with some creative machining. Rollers are great. They reduce friction and heat amazingly well. The cam profiles can be a lot more aggressive without problems at the cam/lifter interface.

But the thing is, the flat tappet lifters aren't in the top 5 things that these engines typically lack. They aren't low-hanging fruit - they're fruit out on the leafy ends of the tippy-top branches, and there's a ton of things you can do before you get to that point.

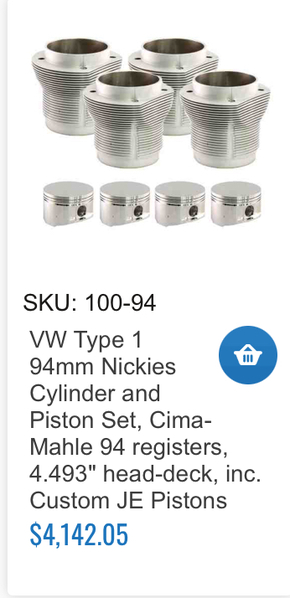

Typical T1 engines have a really hard time with cylinder seal - the cylinders don't want to stay round, and the rings don't want to seat. This is partially a function of poor parts - but even with JE pistons and Total Seal rings, getting a good seal on a Mahle 94 isn't all that easy because the cylinders don't want to stay round. They're thin and they distort as they get hot. Getting this squared up will be worth 10x what a roller cam brings to the table.

As far as the valve-train- the valve-springs are a lot stronger in a typical T1 engine than they are in a lot of applications, because the pushrods are long and there are a lot of harmonics in the valve-train. The typical T1 rocker is kinda flimsy, and the entire setup often requires gentle ramps on the cam and strong valve-springs (which create a lot of heat with the flat tappet). If you just stick a roller lifter and a super-aggressive cam profile on there - yes, there will be less friction and heat, but you will have done nothing to control the valve more accurately. The pushrods will still flex, as will the rockers, and you'll need a killer valve-spring to control the entire mess.

Far, far more productive is to get the weight of the entire arrangement down. Bleeding edge T1s have titanium valves, beehive springs, tapered aluminum pushrods, and the lightest lifters possible, activated by a cam with gentle ramps (opening and closing). Such an engine doesn't need a lot of parlor tricks (like roller rockers) to stay cool, simply because the nose and seat pressure of the valve-springs doesn't need to be crazy high to control the valve. Heat is pretty easily controlled, even running higher than average compression.

This is why the hobby seems like it isn't moving forward. Running lazy ramps, weird pushrods, stout rockers, and titanium valves works really, really well - but it's hard to explain and doesn't seem like a place where spending money gives much return. It doesn't show up on a dyno, but it does show up in your daily life.

If you want to put roller lifters in your car - knock yourself out. I did a twin-plug configuration because I wanted to see why nobody was doing it. Now I know.

Your mileage may vary.