@curtissb, thanks for the info. and photo. Do you still have the rubber flex disc?

no. I eliminated it.

The rack furnished by Alex has 62 splines on the 16mm u-joint connection. I am thinking of using the super Beetle double u-joint piece and cutting the u-joint off one end.

16mm is 5/8". Because the rack has a "flat" on the splined area, the 5/8" x 36 spline adapter fits perfectly.

Here is a picture of my kit still in Finland:

I bought a late Super Beetle shaft with a u-joint on each end. It is about 16" long and it matches the splines on the rack. I will cut the u-joint on one end off and cut it to the length I need.

Attachments

Michael McKelvey posted:

I guess you will get it when they are Finnish with it

Oooooooohhhhhhh........ 😱

He’s here all week folks.

@Michael McKelvey Any word on your rack?

He got it and has been working on it I believe. I'm hoping to see photos. @Michael McKelvey

I have had it for a while but have been working on other things. I sent the pieces out to be powder coated.

After powder coating, I had a lot of trouble reattaching the piece that holds the tie rods on the rack. It was like it shrunk. I had cleaned all holes of powder coat material. I had to use a pretty big hammer to tap it onto the rack shaft. I hope I didn't damage anything inside the rack.

The kit doesn't have any provision for using the steering damper. Alex thinks it isn't needed even though some pictures show it being used in several different configurations. If I really want to use it I would have to drill a hole.

I will probably start on it in the next few days.

I haven't gone beyond the mailbox for about 2 1/2 weeks and now my wife gets the mail. When I needed some lock nuts I ordered them from Amazon instead of going to the hardware store. I am hoping I don't need to get hardware to install the rack.

Attachments

You definitely don’t need the damper with this rack.

i can't see why you would use one, have you seen a damper on a R&P normally? I never have but who knows. I know on some P cars the steering is twitchy.

The 911 never had one. But I could see that MAYBE the trailing arm suspension might need it. It can't hurt.

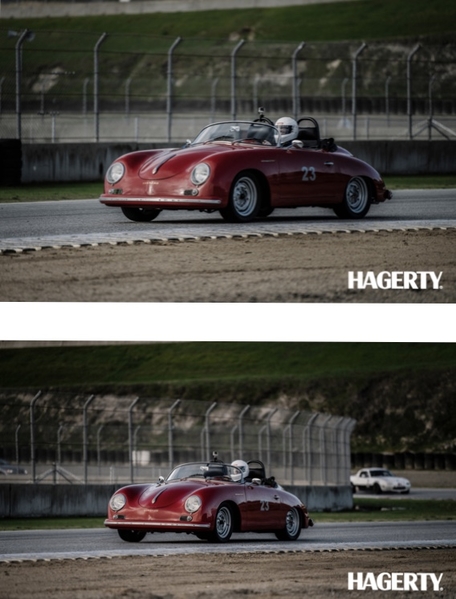

I’ve had this set up for a few years and I even occasionally race my car. There is no need for the damper. It would only slow the steering down.

Very cool, Curtiss. Cone Killer, HPDE, or wheel to wheel?

Last year I had a 150hp 2110 which was fun. This winter I stepped it up and built a 2276 with a dry sump making just over 200hp. I can’t wait to get it back out again.

curtissb posted:Last year I had a 150hp 2110 which was fun. This winter I stepped it up and built a 2276 with a dry sump making just over 200hp. I can’t wait to get it back out again.

Great looking car and I'm sure it'll be wicked! Can you let us in on engine details? Gearing?

I might start a new thread about tracking my car. I can give the motor and chassis details there.

They have this new sensor you can install to that you can track it from a satelite. ![]()

I started a new thread: building a faux cam Carrera track car. It is in the technical general section.

@Michael McKelvey Did you ever finish this project?

Other weirdos that want one want to know.

@DannyP, I thought I was finished but when I turned the steering wheel 180 degrees the horn honked. I discovered the bottom end of the steering shaft was moving around and at one point touched the tube, grounding the horn.

I have installed a Super Beetle bushing in the bottom of the tube. I had to have it turned down a bit to fit. And, I am installing a double u-joint.

I had to shorten the shaft and tube to make room for the double u-joint.

I will post more, with pictures in a few days.

I was out riding the countryside yesterday (it seemed OK at about 90F until you stopped for something ) and noticed that my horn button didn't always make contact and it didn't seem to be steering related.

When I got home I pulled the button off and must have emptied 1/8 of a can of Electrical Contact Cleaner into the housing while swishing it around as much as possible and pushing the button in a bunch. Seems to be working OK, now. That CRC contact cleaner (I got it at NAPA) is pretty good stuff!

Agreed, Michael. I have an early 911 column, double-jointed intermediate shaft and a 911 rack. The rack can't be used(IMHO too much bump steer introduced) but the other parts maybe. The 911 column is SHORT though at 9", and the shaft is about 11" total. I'd rather not re-invent the (steering) wheel, but would if I have to. Sounds like a great winter project.

The intermediate shaft will need shortening, but I like the idea of two joints. That way any misalignment is taken care of by the U-joints. The rack can be centered EXACTLY where it should be.

@Gordon Nichols CRC makes GREAT stuff, indeed. I have some CRC "Lectra-Motive" electric parts cleaner that just plain WORKS.

Danny, you could look at ididit.com for a column but the wheel hub is not close to original.

Sorry what I meant to say or what I should’ve said is that they have column parts that might be useful and universal joints

Thanks Ray. My 911 parts are compatible with the VW Polo rack and the Beetle column.

As mentioned above, I removed the single u-joint and installed a double u-joint and a Super Beetle bushing.

This is the double u-joint. I couldn't find a 16mm x 60 spline double u-joint so I bought a 5/8" by 36 splines double u-joint from kartek.com. It is made by Sweet Mfg. My old single u-joint clamped onto the shafts. The double one uses set screws.

The splined end of the u-joint wouldn't fit over the shaft on the rack so I used a 5/8" drill bit to remove the splines. If you look at the shaft on the rack you can see that it has flat spots at two different depths. It has a shallow one on the end, then a longer, deeper one, then a shallow one again.

I was a bit concerned that with no splines, it was only the set screw that prevented rotation of the u-joint in the shaft or movement of the u-joint along the shaft.

I made a little aluminum piece that I epoxied onto the deeper flat area in the shaft. It will help prevent u-joint rotation or movement along the shaft.

This is the Super Beetle bushing. It replaced the bearing previously used on Super Beetles. I am glad they replaced the bearing because I don't want any electrical connection between the shaft and tube. I hope the Nylatron bushing isn't conductive.

This is the bushing installed in the tube and the modified steering shaft. A 5/8" x 36 spline piece is welded in the end. The splined piece is an Empi part from mooreparts.com. If you get it from them on eBay shipping is free.

This is what the completed installation looks like.

Attachments

No big news yet from me.

I just got a tracking number from Alex. He says 1.5 to 2 weeks.

I have been unable to find a u-joint that matches the splines on the rack. I emailed Alex and he said to use an unsplined connection with a set screw. That is what I have in the photo above. So, I am going to leave things as-is unless a problem develops.

I have two Super Beetle bushings and I installed the tighter one. After driving the car I think maybe I should have used the looser one. There is a little resistance to turning the steering wheel. I hope it will wear a little and free up.

@Michael McKelvey posted:I have been unable to find a u-joint that matches the splines on the rack. I emailed Alex and he said to use an unsplined connection with a set screw.

WOW!!! I'd re-think that one. About as bad a day as you could ever expect is when the set screw doesn't hold. Scares me!

@Jim Gilbert - Madison, Mississippi I clicked the like button ten times but the counter is not incrementing. ![]()

@Michael McKelvey I guess the question is, are you intending to drive it or parade it ?

I plan to drive it. I would be much more concerned about the set screw if it was going on a completely round shaft. I think it is less likely to be a problem going to the flat spot on a D-shaped shaft. I also have the little aluminum piece in there.

The u-joint can't have unlimited rotation on the shaft unless the set screw shears off right where it screws into the u-joint. If the aluminum piece disintegrates and the set screw loosens its grip a bit I would get limited rotation of the u-joint of the shaft. The set screw wouldn't get past the flat spot.

I still would prefer to have a u-joint with splines that match. I would welcome anyone pointing me toward a 16mm 60 spline u-joint.

The setscrew used looks similar to the ones above. It has a nylock nut securing it.

That’s what I get for looking at pics on my phone!

Is there a way for you to drill a countersink into the rack input shaft? I'd do that.