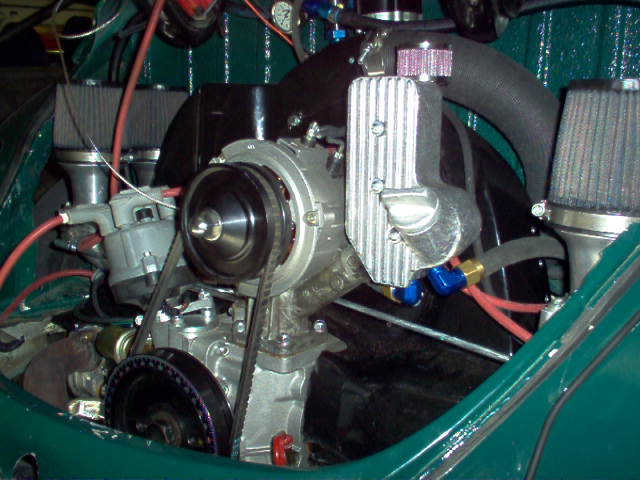

I finished the last (I know, no such thing) detail of Whitecloud's new engine this afternoon. I made up the last hose from the 356 oil filter/breather box and connected it to the air cleaner on passenger side.

The breather box is full of white nylon scrub pads cut round and stuffed into the oil filter to the top. It's been working great but spitting a mist of fine "stuff" all over the engine so I decided it's time to finish what I begun...